Manufacturing method of long fiber nonwoven fabric

A technology of non-woven fabric and manufacturing method, which is applied in the directions of non-woven fabric, fiber treatment, fiber chemical characteristics, etc., can solve the problems of poor dimensional stability, unpublished manufacturing of PPS long fiber non-woven fabric, etc., and achieves stable spinnability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

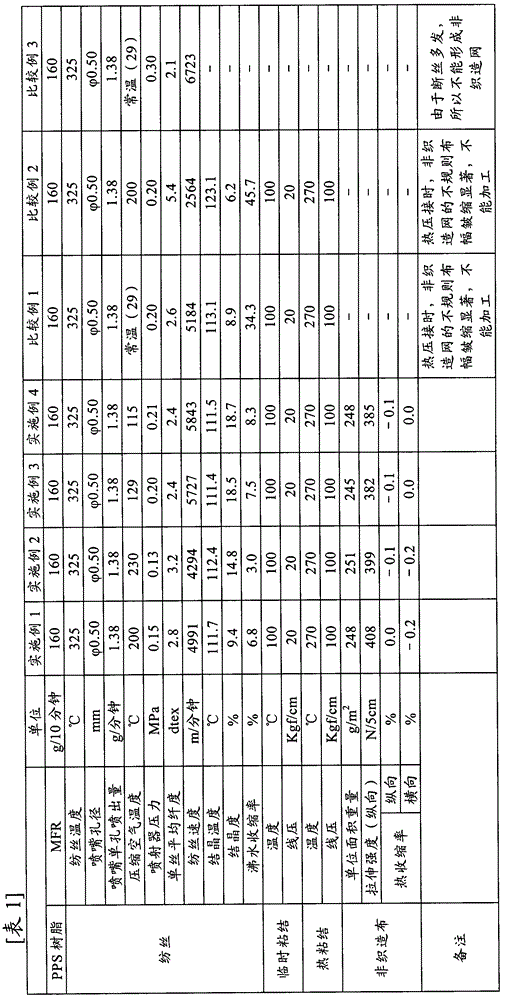

Embodiment 1

[0101] (PPS resin)

[0102] Dry a 100 mol% linear polyphenylene sulfide resin (manufactured by Toray Corporation, product number: E2280, MFR: 160 g / 10 minutes) that is not intended to be copolymerized with trichlorobenzene at a temperature of 160° C. 10 hours, use the resin.

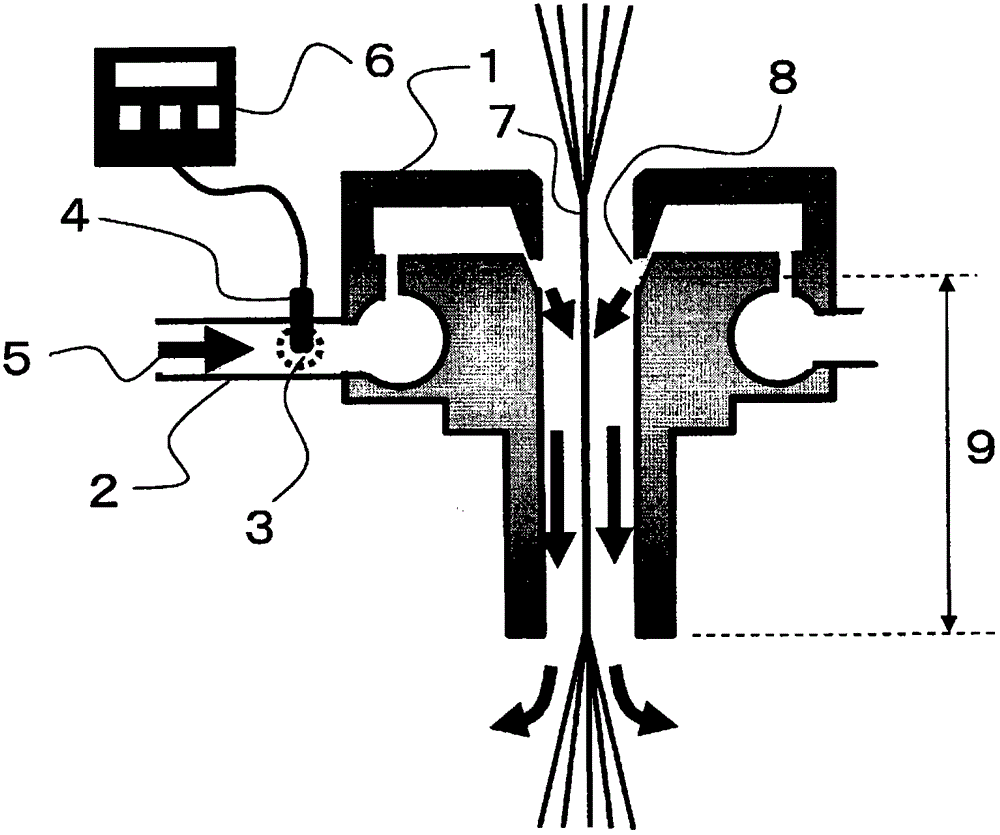

[0103] (spinning and forming nonwoven web)

[0104] Melt the above PPS resin with an extruder, at a spinning temperature of 325°C, from the hole diameter A 0.50 mm rectangular spinneret was spun at a single hole discharge rate of 1.38 g / min. The distance from the rectangular spinneret to the rectangular injector was 55 cm, and the spun filaments were cooled and solidified in an atmosphere at a room temperature of 20°C. Make the cooled and solidified filaments pass through the long 30cm rectangular injector of the injector, inject compressed air from the injector, the compressed gas is heated to a temperature of 200°C with an air heater, and the injector pressure is 0.15MPa, traction, pulling The fil...

Embodiment 2

[0108] (PPS resin)

[0109] The same PPS resin as that used in Example 1 was used.

[0110] (Spinning to form a nonwoven web)

[0111] A nonwoven web was formed by spinning using the above-mentioned PPS resin in the same manner as in Example 1, except that the temperature of the compressed air was 230° C. and the ejector pressure was 0.13 MPa. The obtained long fiber had an average single fiber fineness of 3.2 dtex, a crystallization temperature of 112.4°C, a crystallinity of 14.8%, and a boiling water shrinkage of 3.0%. In addition, the spinning speed was 4,294 m / min, the spinnability was good, and there were no yarn breakages during the one-hour spinning period.

[0112] (Temporary bonding, thermal bonding)

[0113] Next, the nonwoven web was temporarily bonded and thermally bonded in the same manner as in Example 1 to obtain a long-fiber nonwoven fabric. When embossing rollers are used for thermal bonding, the obtained long-fiber nonwoven fabric is also of good quality,...

Embodiment 3

[0115] (PPS resin)

[0116] The same PPS resin as that used in Example 1 was used.

[0117] (spinning and forming nonwoven web)

[0118]A nonwoven web was formed by spinning using the above-mentioned PPS resin in the same manner as in Example 1 except that the temperature of the compressed air was 129° C. and the ejector pressure was 0.20 MPa. The obtained long fiber had an average single fiber fineness of 2.4 dtex, a crystallization temperature of 111.4°C, a crystallinity of 18.5%, and a boiling water shrinkage of 7.5%. In addition, the spinning speed was 5,727 m / min, the spinnability was good, and there was no yarn breakage during the spinning period of 1 hour.

[0119] (Temporary bonding, thermal bonding)

[0120] Next, the nonwoven web was temporarily bonded and thermally bonded in the same manner as in Example 1 to obtain a long-fiber nonwoven fabric. When embossing rollers are used for thermocompression bonding, the quality of the obtained long-fiber nonwoven fabric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com