Acaricide water emulsion composition and preparation method of acaricide water emulsion composition

A mite-killing water emulsion and water-emulsion technology are applied in the field of compound pesticides, which can solve the problems of large environmental pollution and poor acaricidal effect, and achieve the effects of low drug cost, reduced pollution, and reduced drug dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

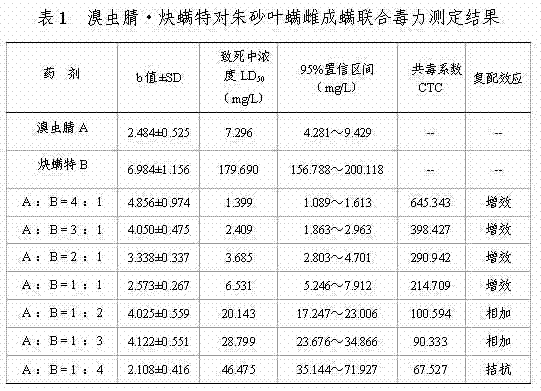

Method used

Image

Examples

Embodiment 1

[0025] Example 1 10% chlorfenapyr-propargite emulsion in water

[0026] Chlorfenapyr 5 g, propargite 5 g, toluene 10 g, No. 33 10 g, ethylene glycol 8 g, xanthan gum 0.6 g, organosiloxane 0.2 g, and water added to 100 g.

[0027] Its preparation process is as follows: melt chlorfenapyr and propargyl acarid solvent (toluene) to form a uniform oil phase; mix emulsifier (No. 33), antifreeze agent (ethylene glycol), thickener (xanthan gum ), antifoaming agent (organosiloxane) and water are stirred and mixed to form a uniform water phase; the oil phase is poured into the water phase, and stirred at 20 ° C for 5 minutes at a speed of 1000 rpm to prepare the described 10% chlorfenapyr-propargite emulsion in water.

Embodiment 2

[0028] Example 2 10% chlorfenapyr-propargite emulsion in water

[0029] Chlorfenapyr 6.7 g, propargid 3.3 g, xylene 20 g, No. 34 18 g, propylene glycol 8 g, gum arabic 0.6 g, gelatin 0.2 g, polyether 0.4 g, water to 100 g.

[0030] Its preparation process is as follows: melt chlorfenapyr and propargyl acarid solvent (xylene) to form a uniform oil phase; mix emulsifier (No. 34), antifreeze agent (propylene glycol), thickener (gum arabic and gelatin) ), antifoaming agent (polyether) and water were stirred and mixed to form a uniform water phase; stirred at 21°C for 8 minutes at a speed of 1200 rpm, and poured the water phase into the oil phase to form the 10 % Chlorfenapyr · propargite emulsion in water.

Embodiment 3

[0031] Example 3 10% chlorfenapyr-propargite emulsion in water

[0032]Chlorfenapyr 7.5 g, propargite 2.5 g, toluene 20 g, propylene glycol 10 g, Tween 20 18 g, urea 6 g, sodium alginate 2 g, natural rubber 6 g, organic silicone 0.4 g, water added to 100g.

[0033] Its preparation process is as follows: melt chlorfenapyr and propargyl acarid special solvent (toluene) to form a uniform oil phase; mix emulsifier (Tween 20), antifreeze agent (urea), thickener (sodium alginate and Natural rubber), antifoaming agent (organic silicone) and water are stirred and mixed to form a uniform water phase; the oil phase is poured into the water phase, and stirred at 22 ° C for 10 minutes at a speed of 1500 rpm to obtain the prepared The 10% chlorfenapyr-propargite aqueous emulsion mentioned above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com