Recovery processing method for low-concentration stray smoke S02

A recycling, low-concentration technology, applied in the fields of chemical and metallurgical engineering, can solve problems such as low absorption efficiency, environmental pollution, and excessive discharge, and achieve the effects of high absorption efficiency, reduction of environmental pollution, and effective recovery and treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

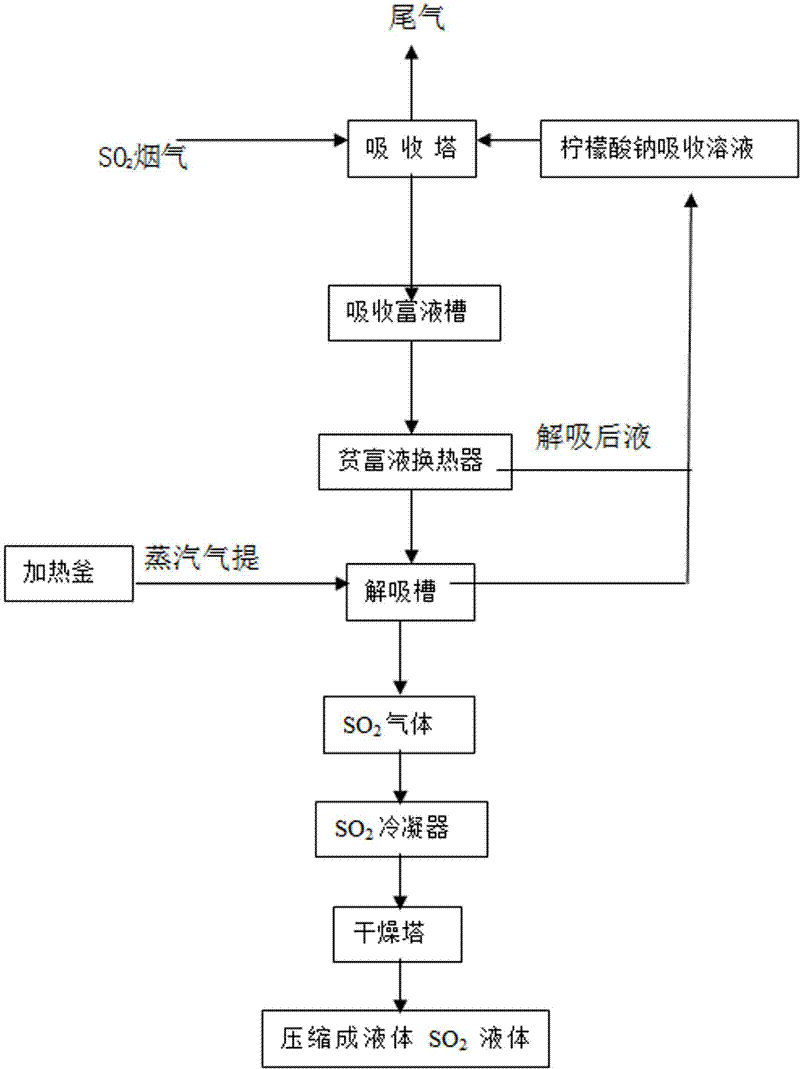

[0012] A low-concentration stray flue gas SO 2 Recycling method, the concrete steps of the method are:

[0013] (1) The low-concentration flue gas enters the bottom of the absorption tower after being cooled, and is in countercurrent contact with the lean liquid sprayed down from the top to complete the absorption process to the maximum extent. 2 The tail gas of the flue gas is tested and then vented. At this time, the S0 in the tail gas 2 The volume fraction does not exceed 0.05%;

[0014] (2) The absorption liquid in (1) enters the rich liquid tank, and the rich liquid and water vapor are countercurrently contacted in the desorption tower, and the water vapor passing through the condenser is condensed, and S0 with a volume fraction of more than 90% is separated. 2 gas;

[0015] (3) Most of the S0 is removed from the absorption liquid 2 After becoming poor liquid, it enters the absorption tower for recycling. That is, the absorption liquid circulates between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com