Multi-morphology rare earth doped BiVO4 composite photocatalyst and preparation method thereof

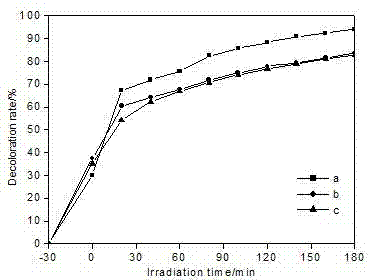

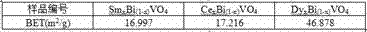

A rare earth doping and catalyst technology, applied in the field of photocatalytic materials, can solve the problems of limited utilization by humans, and achieve the effects of controllable morphology and structure, high photocatalytic degradation effect, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

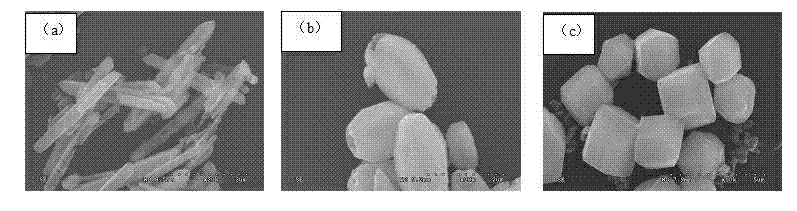

[0021] Embodiment 1: Synthesize Sm-doped BiVO according to the following steps 4 :

[0022] 1) Weigh 2.425g Bi(NO 3 ) 3 ?5H 2 O dissolved in 10mL 2mol / L HNO 3 solution, then add 0.9304g of EDTA and ultrasonically dissolve for 30min to obtain solution a, weigh 0.5800g NH 3 VO 4 Dissolved in 20mL of 2mol / L NaOH solution to obtain solution b;

[0023] 2) Gradually add the above solution b to the solution a dropwise under constant stirring, and add 0.0005mol of Sm(NO 3 ) 3 , continue to stir for 1h to obtain a yellow suspension, then add 10mL of absolute ethanol and continue to stir for 2h to obtain a reaction precursor;

[0024] 3) Move the reaction precursor to a stainless steel reactor lined with white polytetrafluoroethylene, and put it in a 140°C constant temperature box for hydrothermal treatment for 6 hours;

[0025] 4) Extract the reaction product by filtration, wash the obtained product with deionized water and absolute ethanol for 2 to 3 times until the pH of t...

Embodiment 2

[0026] Embodiment 2: BiVO of Ce is synthesized according to the following steps 4 :

[0027] 1) Weigh 2.425g Bi(NO 3 ) 3 ?5H 2 O dissolved in 5mL 4mol / L HNO 3 solution, then add 0.9304g of EDTA and ultrasonically dissolve for 20min to obtain solution a, weigh 0.5510g NH 3 VO 4 Dissolved in 10mL of 4mol / L NaOH solution to obtain solution b;

[0028] 2) Gradually add the above solution b to the solution a dropwise under constant stirring, and add 0.001mol of Ce(NO 3 ) 3 , continue stirring for 30 minutes to obtain a yellow suspension, then add 15 mL of absolute ethanol and stir for 1 hour to obtain a reaction precursor;

[0029] 3) Move the reaction precursor to a stainless steel reactor lined with white polytetrafluoroethylene, and put it in a 120°C constant temperature box for hydrothermal treatment for 6 hours;

[0030] 4) Extract the reaction product by filtration, wash the obtained product with deionized water and absolute ethanol for 2 to 3 times until the pH val...

Embodiment 3

[0031] Embodiment 3: Synthesize Dy-doped BiVO according to the following steps 4 :

[0032] 1) Weigh 2.425g Bi(NO 3 ) 3 ?5H 2 O dissolved in 2.5mL 6mol / L HNO 3 solution, then add 0.9304g of EDTA and ultrasonically dissolve it for 10min to obtain solution a, weigh 0.5220g NH 3 VO 4 Dissolved in 5mL of 6mol / L NaOH solution to obtain solution b;

[0033] 2) Gradually add the above solution b to the solution a dropwise under constant stirring, and add 0.00025mol of Dy(NO 3 ) 3 , continue to stir for 30 minutes to obtain a yellow suspension, then add 20 mL of absolute ethanol for 30 minutes to obtain a reaction precursor;

[0034] 3) Move the reaction precursor to a stainless steel reactor lined with white polytetrafluoroethylene, and put it in a 160°C constant temperature box for hydrothermal treatment for 4 hours;

[0035] 4) Extract the reaction product by filtration, wash the obtained product with deionized water and absolute ethanol 2 to 3 times until the pH value of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com