Preparation method of polyurethane elastomer for engineering tire treads

A polyurethane elastomer, engineering tire technology, used in special tires, tire parts, transportation and packaging, etc., can solve the problems of complex production process, environmental pollution, short life of rubber tires, etc., to achieve simple processing technology, wear resistance, etc. The effect of improving and reducing rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

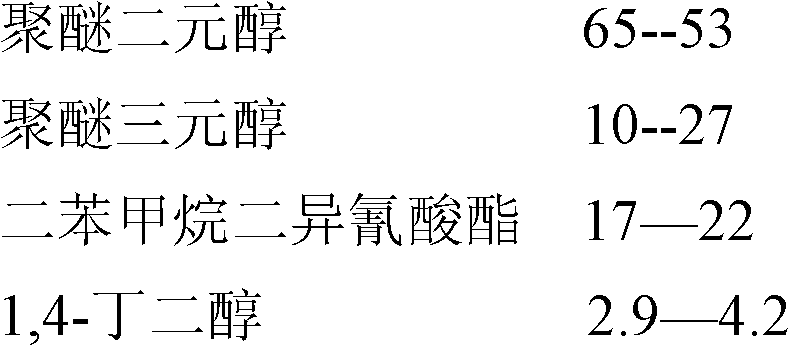

[0015] The polyurethane elastomer that is used for engineering tire tread is synthesized by two-step method, and the isocyanate radical content of prepolymer is set at 3%, and raw material proportioning is configured by following weight percentage:

[0016]

[0017] The sum of the weight percentages of the above four raw materials is 100%, and the catalyst dibutyltin dilaurate is 0.23% of the total amount of raw materials

[0018] After the ratio of raw materials is selected, the specific production process is carried out:

[0019] First, add polytetrahydrofuran diol into the three-necked flask, heat the oil bath to 125°C, start stirring under vacuum conditions, dehydrate for 2.5 hours, then cool down to 60°C, add the measured MDI, let it heat up naturally for 15 minutes, and heat to 80°C. React at a constant temperature for 2 hours, then take a sample and titrate to measure the -NCO content, stop the reaction when it reaches the preset value, then debubble for 30 minutes u...

Embodiment 2

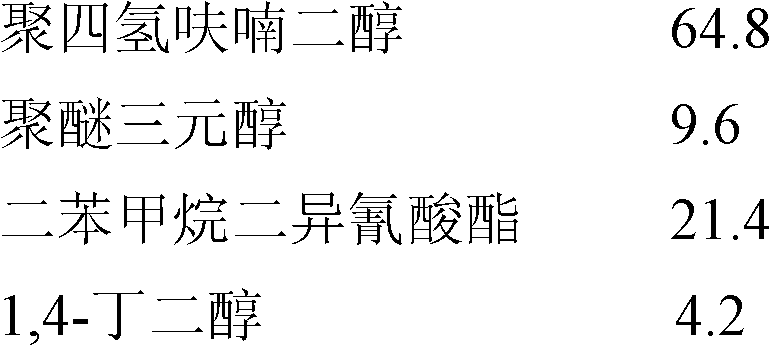

[0021] The polyurethane elastomer that is used for engineering tire tread is synthesized by two-step method, and the isocyanate radical content of prepolymer is set to 4%, and raw material proportioning is configured by following weight percentage:

[0022]

[0023] The sum of the weight percentages of the above four raw materials is 100%, and the catalyst dibutyltin dilaurate is 0.23% of the total amount of raw materials

[0024] After the ratio of raw materials is selected, the specific production process is carried out:

[0025] First, add polytetrahydrofuran diol into the three-necked flask, heat the oil bath to 130°C, start stirring under vacuum conditions, dehydrate for 2.5 hours, then cool down to 59°C, add the measured MDI, let it heat up naturally for 15 minutes, and slowly heat to 83°C, constant temperature reaction for 2 hours, then sampling and titration to measure -NCO content, the reaction can be stopped when the preset value is reached, and then vacuum degass...

Embodiment 3

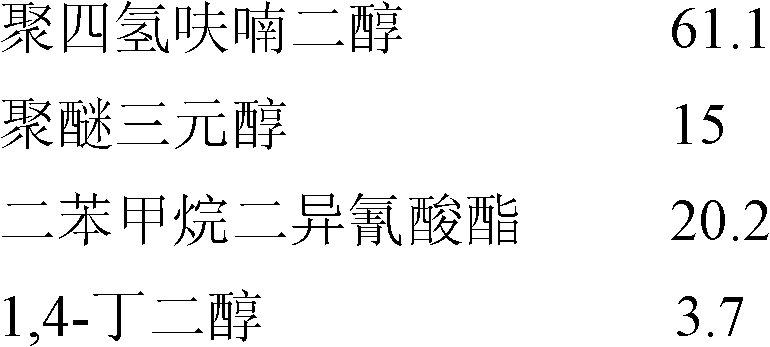

[0027] The polyurethane elastomer that is used for engineering tire tread is synthesized by two-step method, and the isocyanate radical content of prepolymer is set to 6%, and raw material proportioning is configured by following weight percentage:

[0028]

[0029] The sum of the weight percentages of the above four raw materials is 100%, and the catalyst dibutyltin dilaurate is 0.23% of the total amount of raw materials

[0030] After the ratio of raw materials is selected, the specific production process is carried out:

[0031] First, add polytetrahydrofuran diol into the three-necked flask, heat the oil bath to 120°C, start stirring under vacuum conditions, dehydrate for 3 hours, then cool down to 65°C, add the measured MDI, let it heat up naturally for 15 minutes, and slowly heat to 75°C ℃, constant temperature reaction for 2.5 hours, and then sample titration to measure -NCO content, the reaction can be stopped when the preset value is reached, vacuum degassing for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com