Low-smoke type antimonous oxide compound fire retardant and preparation method thereof

A technology of antimony trioxide and compound flame retardant, which is applied in the chemical industry, can solve the problems of smoldering, toxic gas, large smoke generation, etc., and achieves the promotion of full mixing, reduction of mechanical properties, and improvement of compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

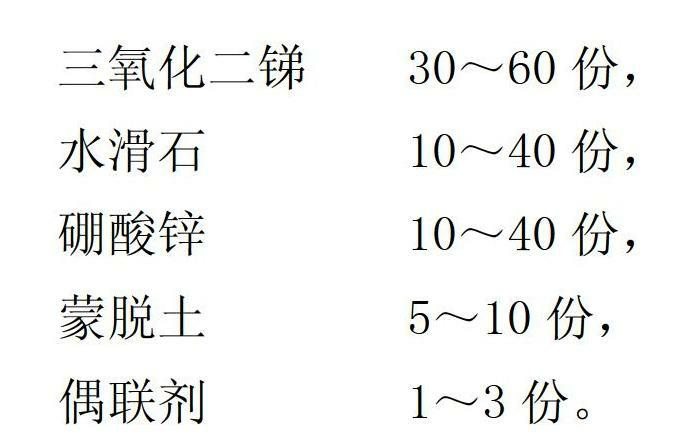

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh raw materials of low-smoke antimony trioxide compound flame retardant: 30 kg of antimony trioxide (main content above 99.6%), 10 kg of hydrotalcite, 10 kg of zinc borate, 5 kg of organically modified montmorillonite kg, 1 kg of titanate coupling agent;

[0034] (2) Put the above-mentioned prepared components into a high-speed mixer with water cooling function and mix evenly. The mixing time is 30 minutes, and the temperature of the material in the mixer is controlled below 100°C during the mixing process;

[0035] (3) Transport the uniformly mixed materials to the vibrating screen for preliminary screening, remove large particles or agglomerated materials, and then transport the preliminary screened materials to the centrifugal sieve for secondary screening; vibrating screen model: Zxs1000 type, motor 1.5kw, speed: 1100rpm; centrifugal sieve type: kemutec k650 type;

[0036] (4) Transport the materials screened out from the centrifugal sieve to the packaging ...

Embodiment 2

[0038] (1) Weigh low-smoke type antimony trioxide compound flame retardant raw materials: 60 kg of antimony trioxide (main content above 99.6%), 40 kg of hydrotalcite, 40 kg of zinc borate, 10 kg of organically modified montmorillonite kg, 3 kg of aluminate coupling agent;

[0039] (2) Put the above-mentioned prepared components into a high-speed mixer with water cooling function and mix evenly. The mixing time is 35 minutes, and the temperature of the material in the mixer is controlled below 100°C during the mixing process;

[0040] (3) Transport the uniformly mixed materials to the vibrating screen for preliminary screening, remove large particles or agglomerated materials, and then transport the preliminary screened materials to the centrifugal sieve for secondary screening; vibrating screen model: Zxs1000 type, motor 1.5kw, speed: 1100rpm; centrifugal sieve type: kemutec k650 type;

[0041] (4) Transport the materials screened out from the centrifugal sieve to the packag...

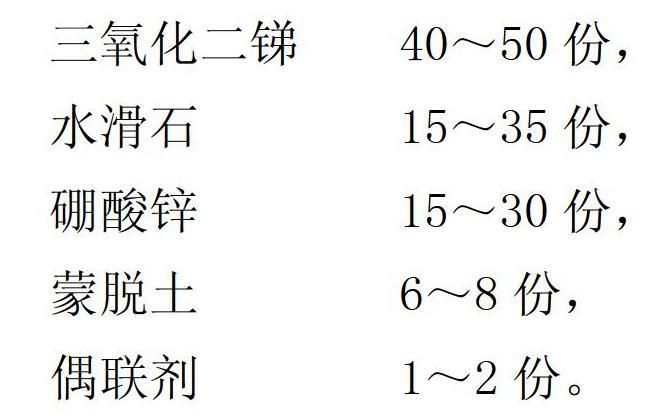

Embodiment 3

[0043] (1) Weigh raw materials of low-smoke antimony trioxide compound flame retardant: 40 kg of antimony trioxide (main content above 99.6%), 15 kg of hydrotalcite, 15 kg of zinc borate, 6 kg of organically modified montmorillonite kg, 1 kg of titanate coupling agent;

[0044] (2) Put the above-mentioned prepared components into a high-speed mixer with water cooling function and mix evenly. The mixing time is 55 minutes, and the temperature of the material in the mixer is controlled below 100°C during the mixing process;

[0045] (3) Transport the uniformly mixed materials to the vibrating screen for preliminary screening, remove large particles or agglomerated materials, and then transport the preliminary screened materials to the centrifugal sieve for secondary screening; vibrating screen model: Zxs1000 type, motor 1.5kw, speed: 1100rpm; centrifugal sieve type: kemutec k650 type;

[0046] (4) Transport the materials screened out from the centrifugal sieve to the packaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com