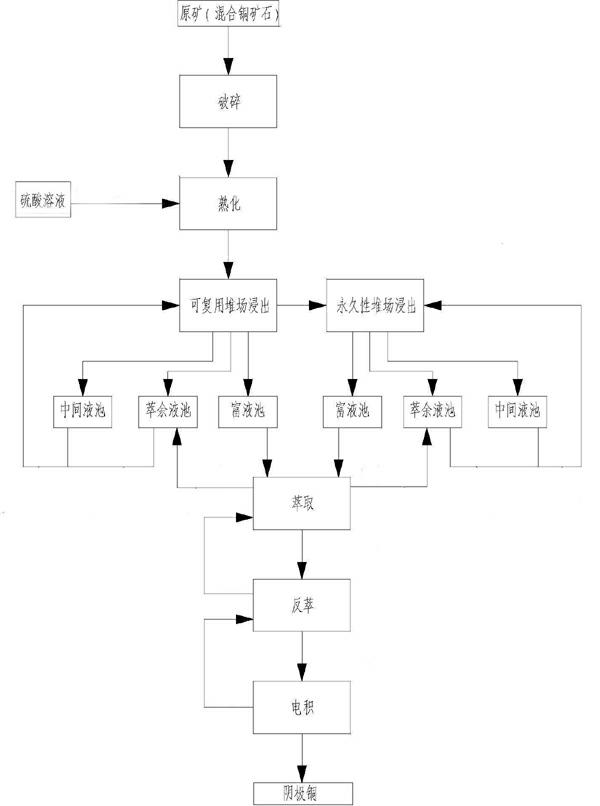

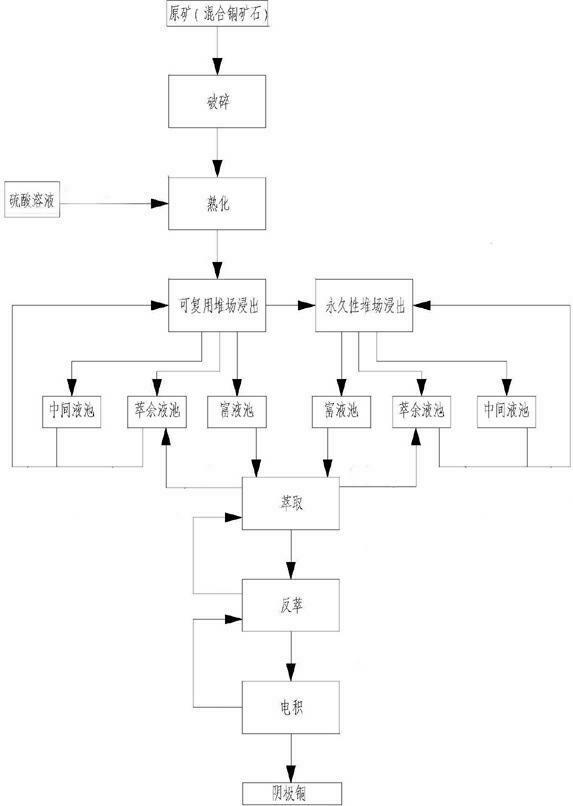

Stage-by-stage dump leaching technology for low-grade mixed copper ore

A mixed copper ore, low-grade technology, applied in the direction of improving process efficiency, can solve the problems of poor flotation effect of copper oxide minerals, high operating costs, low copper recovery rate, etc., and is conducive to effective recovery and heap leaching. Short cycle time and the effect of improving leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a copper mine, the above-mentioned steps are used for step-by-step heap leaching. The copper metal in the copper oxide minerals with a fast leaching speed is recovered in the heap leaching stage of the reusable stockyard, and the copper metal in the copper sulfide minerals with a slow leaching speed is recovered. Copper metal is recycled in permanent storage yards, and the copper leaching rate is 10-15% higher than that of conventional heap leaching methods.

[0037] The copper mine is a porphyry-type copper deposit, which is a low-grade mixed copper ore, and its content ratio of copper oxide ore and copper sulfide ore is about 3:1. Copper oxide ores are mainly malachite, azurite and chrysocolla; copper sulfide ores are mainly chalcocite and bornite; gangue minerals are mainly feldspar, quartz and biotite.

[0038] The low-grade mixed copper ore contains 0.42% copper, and the daily raw ore processing scale of the mine is 7000t. The processing technology of this mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com