On-line atomic layer deposition device and deposition method

A technology of atomic layer deposition and carrying device, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of complex loading components and substrate carrying devices, shorten the flushing time, reduce configuration, and facilitate Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

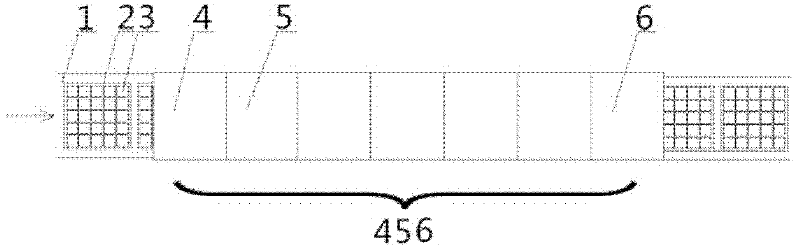

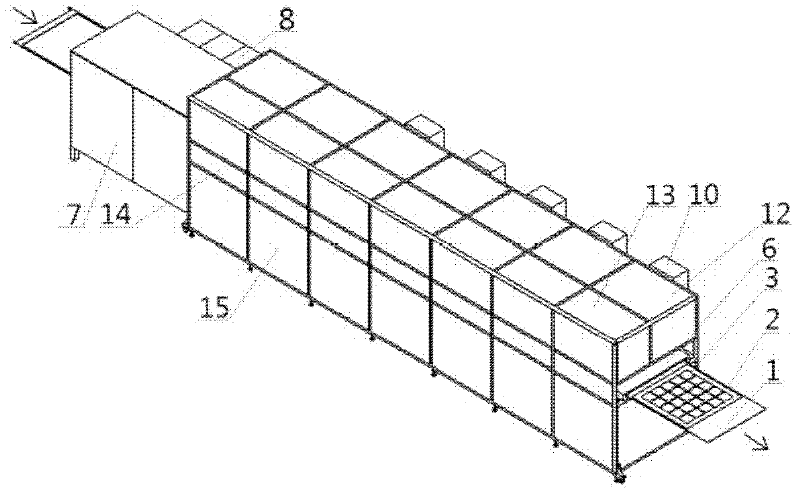

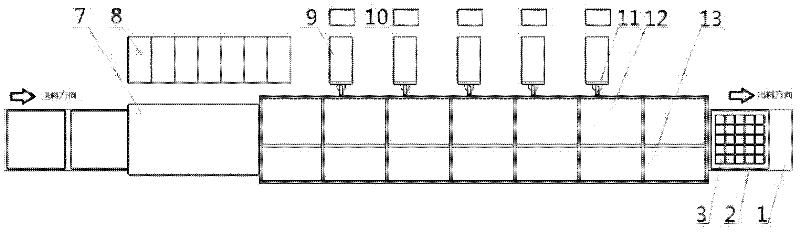

[0052] see Figure 1~5 As shown, the invention is applied in the photovoltaic field, and the size is 156×156mm under low voltage 2 A passivation film of aluminum oxide with a thickness of 15 nm was deposited on the solar panel substrate. The device includes a preheating chamber 4, five sequentially arranged ALD reaction chambers 5, a cooling chamber 6, a substrate feeding system 1, a precursor feeding system 13, a heating system, loading and unloading elements 7, and lifting elements 19 , control and detection system 12, vacuum pump 9, vacuum pipeline 11, electrical cabinet 8 and tail gas treatment system. exist figure 1 In , five reaction chambers are arranged sequentially between a preheating chamber and a cooling chamber. The reaction precursors are TMA and H 2 O or O 3 . Flushing gas is N 2 .

[0053] The substrate feeding system 1, loading and unloading components 7, heating system, exhaust gas treatment system and control and detection system 12 are shared by all...

Embodiment 2

[0056] An atomic layer deposition apparatus, which is different from Embodiment 1 in that it does not include a vacuum pump 9 and a vacuum pipeline 11, but is equipped with a fan to pump air into a closed reaction chamber formed by the substrate carrying system 2 and the upper covers 18 of each chamber . This device is used for the ALD method under normal pressure with a size of 156×156mm 2 A 15nm aluminum oxide passivation film was deposited on the solar panel substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com