Heating system using biomass as boiler fuel and vertical energy-saving boiler

A boiler fuel and biomass technology, applied in the direction of solid fuel combustion, water heaters, fluid heaters, etc., can solve the problems of energy saving and emission reduction, low thermal efficiency, and increased equipment costs, so as to reduce pollution and coal resources The effect of energy consumption, increasing the heating area and volume, and reducing the loss of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

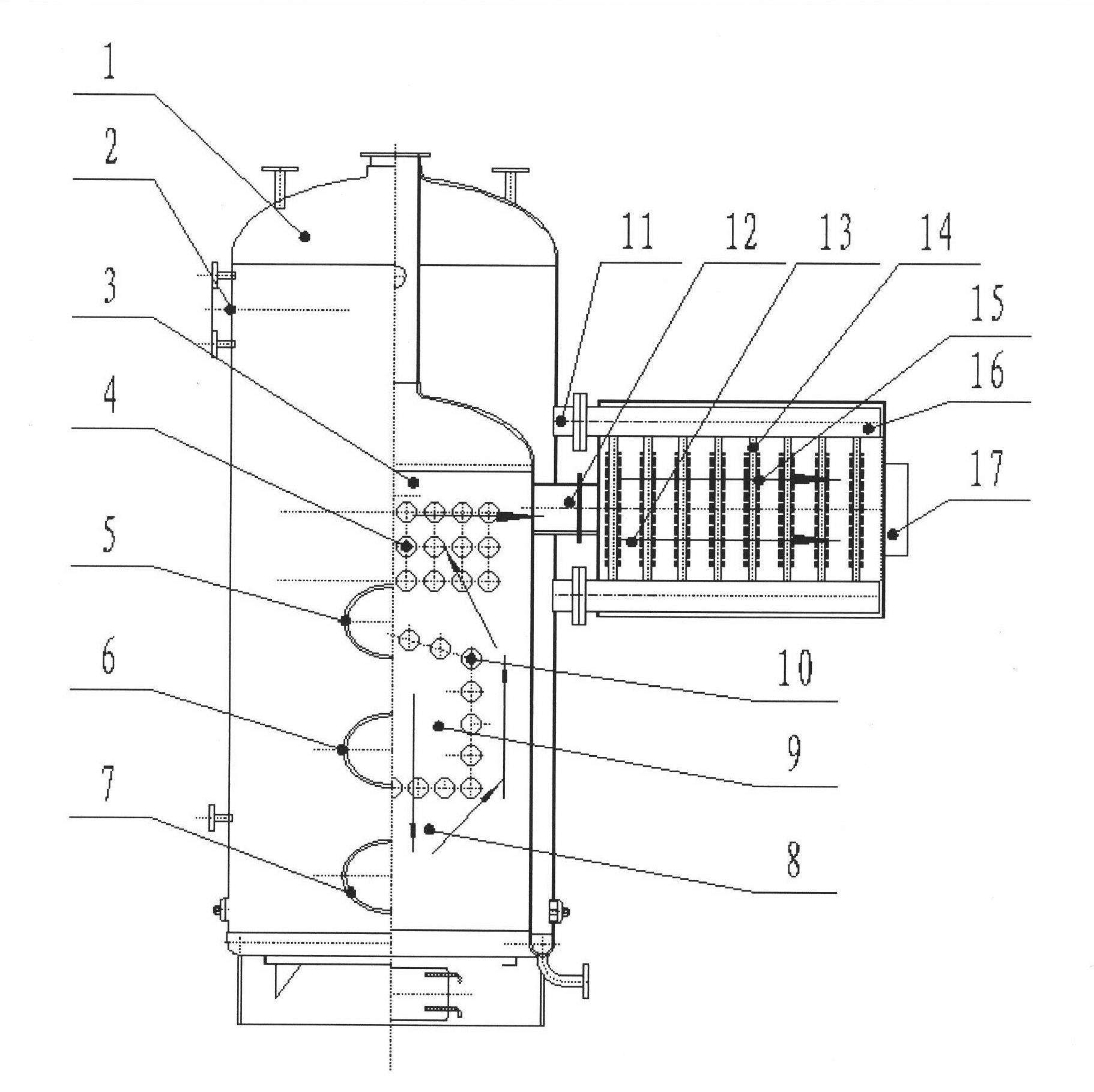

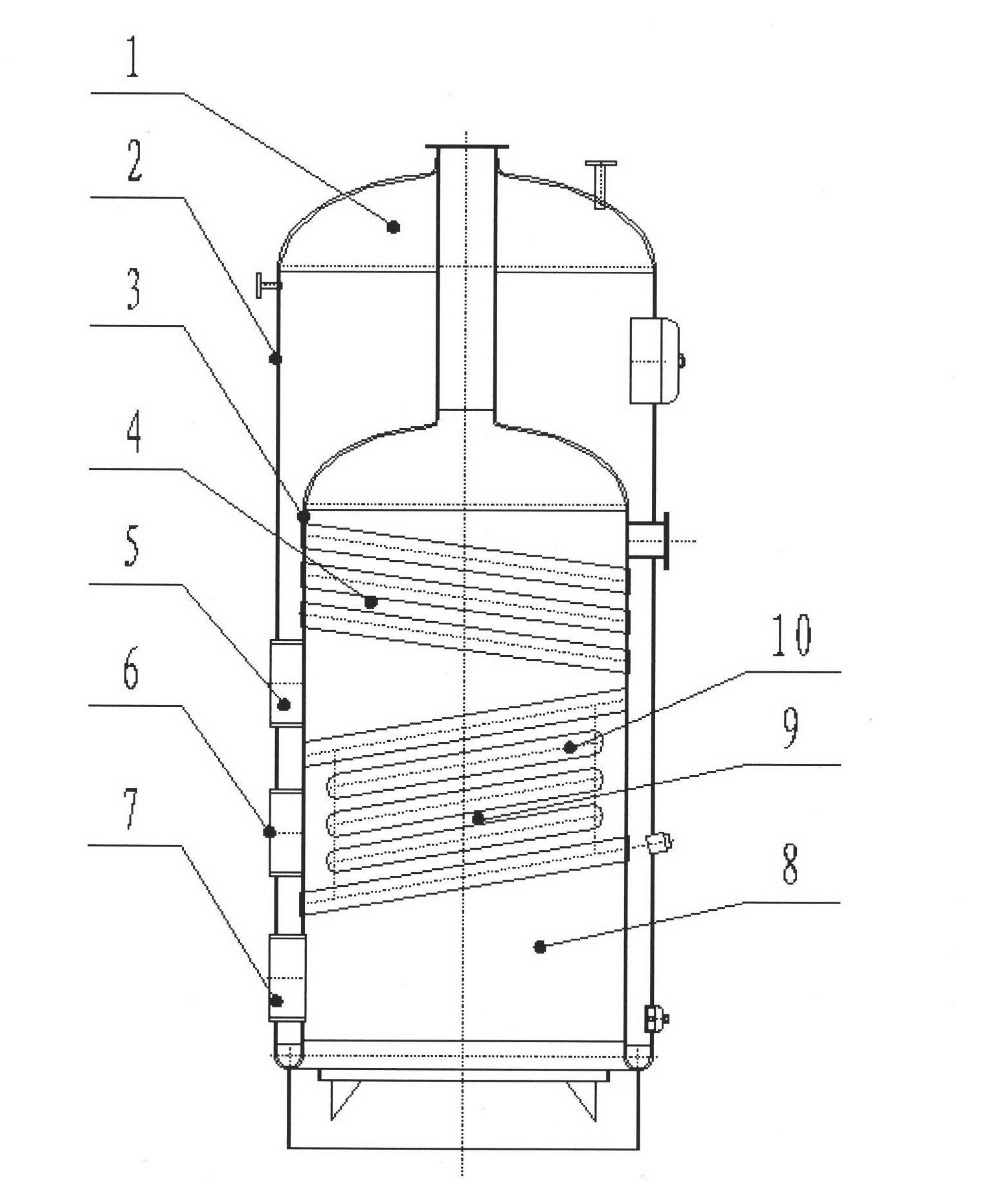

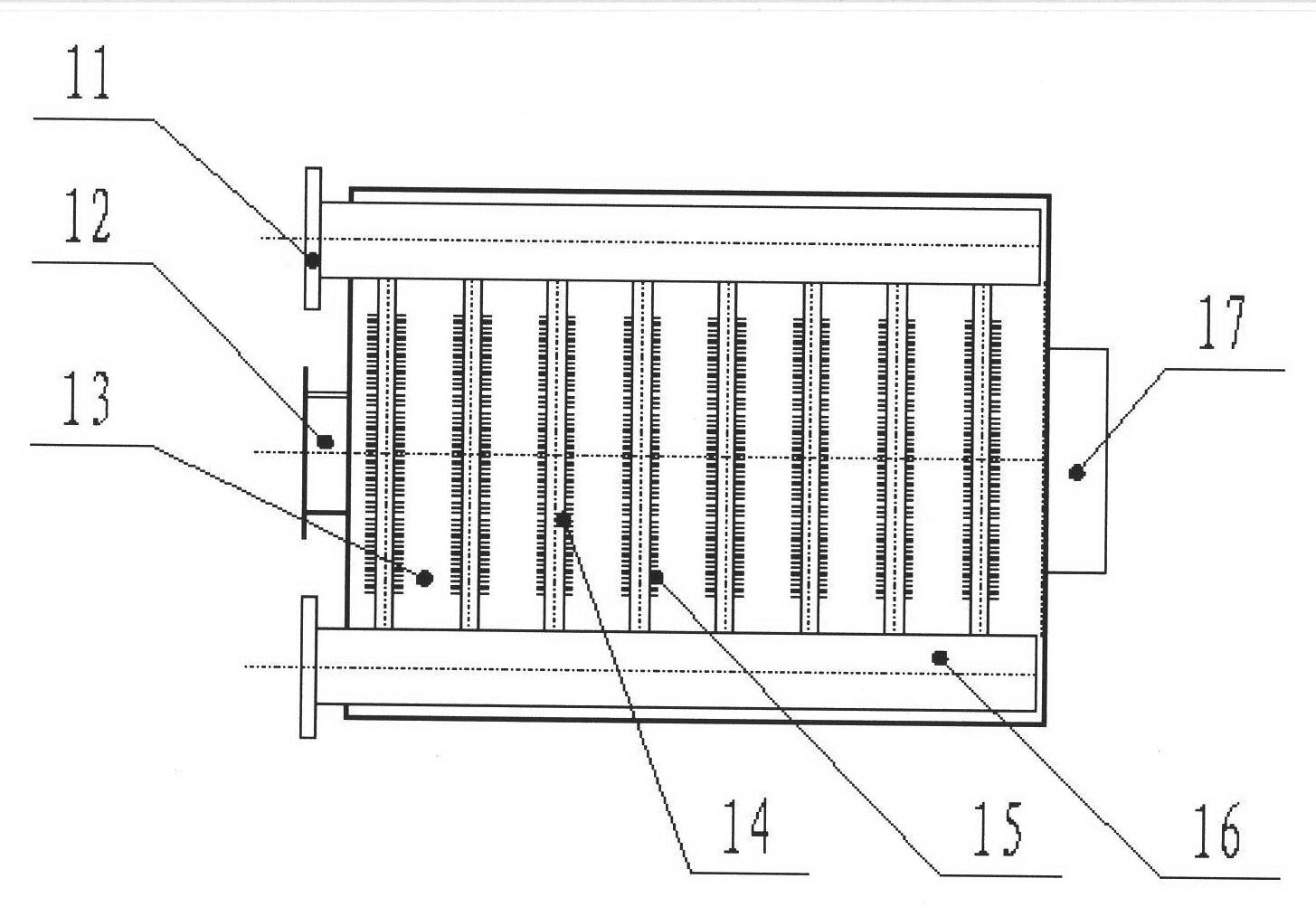

[0023] Such as figure 1 , 2 , 3, and 4 show a heating system and a vertical energy-saving boiler using biomass as boiler fuel. This boiler is a vertical water tube double-layer grate shell boiler. Composed of water pipes, economizers, chimneys and pipeline valves and instruments.

[0024] The boiler body is welded by a pot shell 2, a head 1, a furnace 3 and a furnace top, and a U-shaped foot ring, and is vertically arranged.

[0025] The inner upper layer of the furnace 3 is a horizontal water pipe 4, and the lower layer is a cold water wall pipe 10 cast iron grate, which are connected to the inner wall of the furnace respectively, and double-layer grate is used for reverse combustion. The feed inlet 6 is connected to the furnace 9, the biomass fuel enters the furnace 9, the radiant heating surface forms the combustion chamber 8, the combustion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com