Method for measuring content of mixed ester in nitro paint cloth

A determination method and mixed ester technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of long analysis time and complicated operation procedures, achieve high analysis success rate, reduce extraction operation process, and meet production timeliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

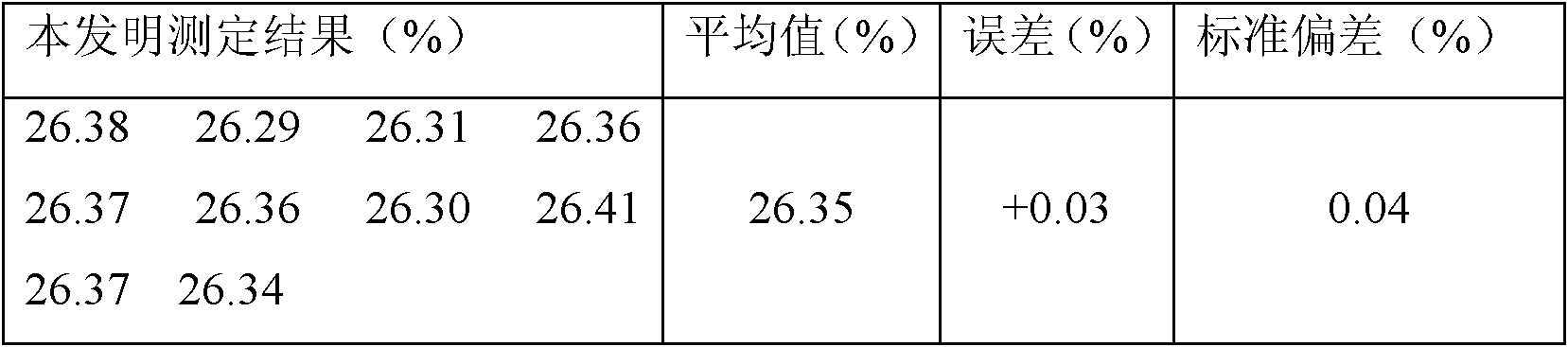

[0027] The standard value of the content of mixed ester in the sample of embodiment 1 is 26.33%

[0028] Adopt same sample to measure ten times respectively with the present invention and existing method respectively, and measurement result contrast is as follows:

[0029] The result that table 1 embodiment 1 sample adopts the method analysis of the present invention to measure

[0030]

[0031] Table 2 Example 1 sample adopts existing method to analyze and measure the result

[0032]

Embodiment 2

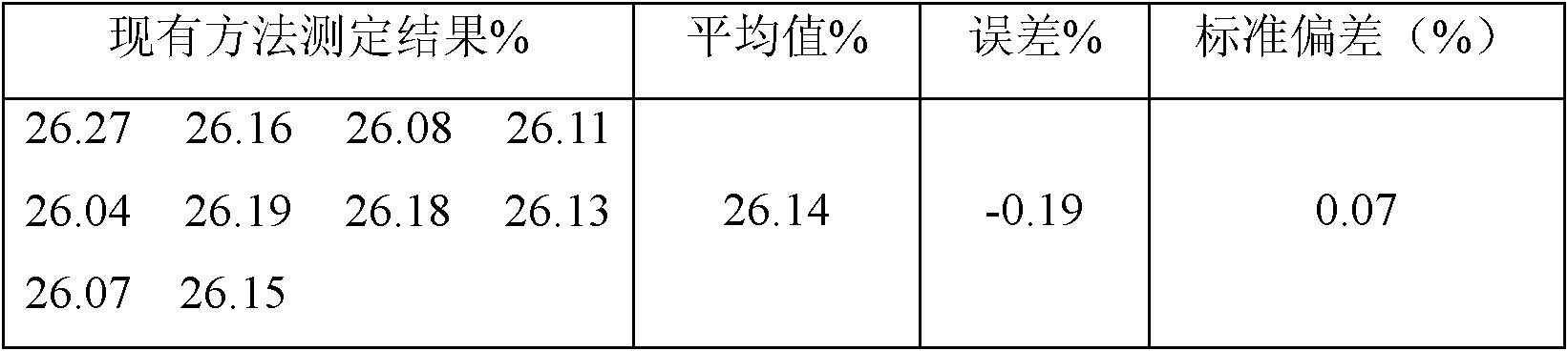

[0033] The standard value of the content of mixed ester in the sample of embodiment 2 is 25.86%

[0034] Embodiment 2 sample adopts the result that the present invention analyzes and measures

[0035]

[0036] Embodiment 2 sample adopts existing method analysis to measure the result

[0037]

Embodiment 3

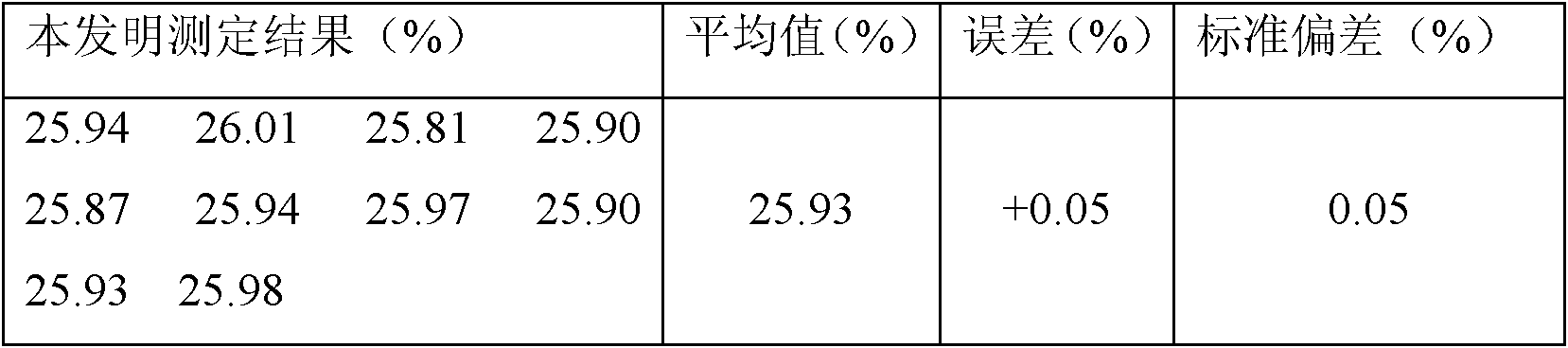

[0038] The standard value of the content of mixed ester in the sample of embodiment 3 is 27.17%

[0039] Embodiment 1 sample adopts the result that the present invention analyzes and measures

[0040]

[0041] Embodiment 1 sample adopts the result that existing method analysis measures

[0042]

[0043] It can be seen from the above data that the accuracy of the analysis results of the present invention is high, and the analysis precision is also very good.

[0044] The present invention adopts dichloromethane or chloroform as extractant, can selectively extract the mixed ester and neutralizing agent in the sample, boric acid, chrysotile and nitrocellulose are not extracted, thereby reducing the extraction operation process, making The operation is simplified; the sample will not agglomerate, so the filter cup will not be blocked; it only takes 4 hours to analyze a sample, which can well meet the production timeliness requirements. In addition, because the operation proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com