Experimental immersed projective lithography objective lens

A projected light and immersion technology, which is applied in the field of high-resolution projection lithography objective lens, can solve the problems of complex structure of total refraction lithography projection objective lens, low-frequency contrast reduction, long system length, etc., and achieve simple structure and high numerical aperture. , Guarantee the effect of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better illustrate the purpose and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

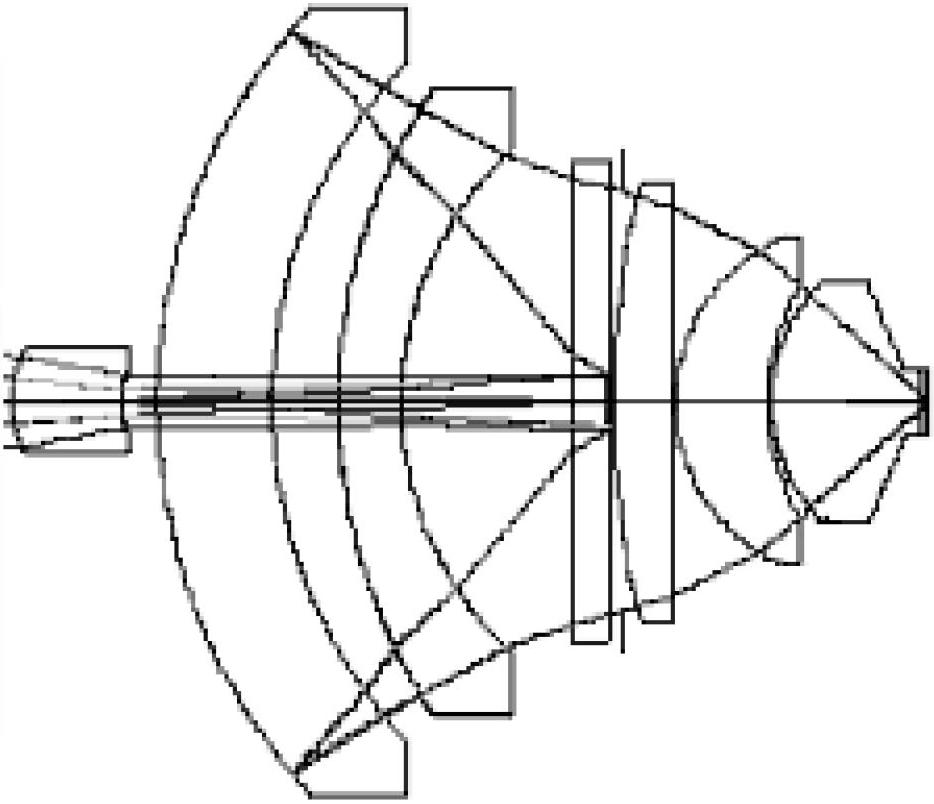

[0035] An experimental immersion projection lithography objective lens of the present invention comprises a first positive lens L1, a second Mankin concave mirror L2, a diaphragm, and a third Mankin lens arranged in sequence on the same optical axis from the mask plate to the photolithography surface. Gold convex mirror L3, the fourth meniscus lens L4, the fifth meniscus lens L5, the sixth meniscus lens L6, the seventh meniscus lens L7, the eighth plano-convex lens L8 and the ninth deionized water layer L9, wherein:

[0036] The second Mankin concave mirror L2 and the third Mankin convex mirror L3 form a Schwarzschild reflective structure, which is used to improve the image-side numerical aperture of the lithography system and ensure a working bandwidth of 70pm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius of curvature | aaaaa | aaaaa |

| Clear aperture | aaaaa | aaaaa |

| Clear aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com