OLED (organic light-emitting diode) device, AMOLED (active matrix organic light-emitting diode) device and manufacturing method of AMOLED device

A device and anode layer technology, which is applied in the field of lighting device and display device manufacturing, can solve the problems of complex manufacturing process and high production cost of AMOLED devices, achieve the effects of shortening production time, reducing manufacturing process, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

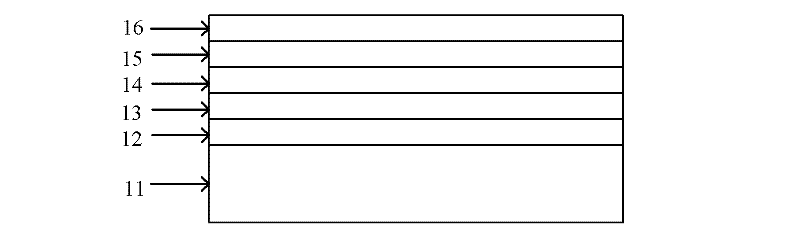

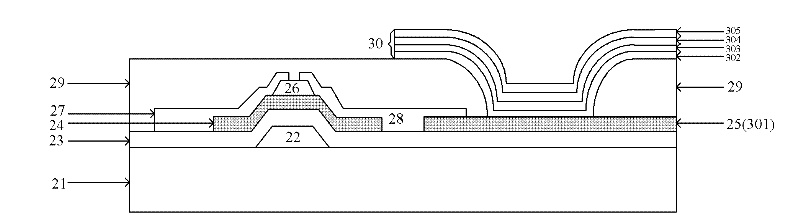

[0060] As the first embodiment of the manufacturing method of the AMOLED device provided by the present invention, as Figure 9 , the method includes the following steps,

[0061] 501. Clean the substrate 21. SiO with a thickness of 200nm was deposited by CVD method 2 The thin film acts as a buffer layer. Metal Mo with a thickness of 200 nm is deposited by sputtering, and the gate electrode 22 is obtained by photolithography and etching. SiO with a thickness of 150 nm was deposited at 370 °C by CVD method 2 as the gate insulating layer 23 .

[0062] 502 . Deposit an IGZO film layer with a thickness of 50 nm by sputtering, and perform photolithography and etching to obtain the active layer 24 and the pixel electrode layer 25 .

[0063] 503. Deposit SiO with a thickness of 50 nm by sputtering 2 Layer, photolithography, etching to obtain the barrier layer 26.

[0064] 504. Deposit a metal layer with a thickness of 200 nm by using a sputtering method, where the metal layer ...

no. 3 example

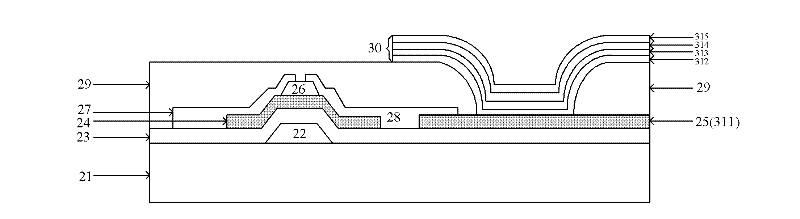

[0079] As the third embodiment of the manufacturing method of the AMOLED device provided by the present invention, as Figure 11 , the method includes the following steps,

[0080] 701. Clean the substrate 21. An Al layer with a thickness of 150-300 nm is vapor-deposited on the back of the substrate 21 as a mirror. Metal Mo with a thickness of 200 nm is deposited by sputtering, and the gate electrode 22 is obtained by photolithography and etching. SiO with a thickness of 120 nm was deposited at 390 °C by CVD method 2 and SiN x as the gate insulating layer 23 .

[0081] 702. Deposit an IGZO thin film layer with a thickness of 50 nm by sputtering, and obtain the active layer 24 and the pixel electrode layer 25 by photolithography and etching.

[0082] 703. Deposit SiO with a thickness of 50 nm by sputtering 2 Layer, photolithography, etching to obtain the barrier layer 26.

[0083] 704. Deposit a metal layer with a thickness of 200 nm by using a sputtering method, where t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Deposition thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com