Synthesis method of massoia lactone

A technique of massoia lactone and a synthetic method, applied in the direction of organic chemistry and the like, can solve the problems of no commercial value, high cost of raw materials, cumbersome steps and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

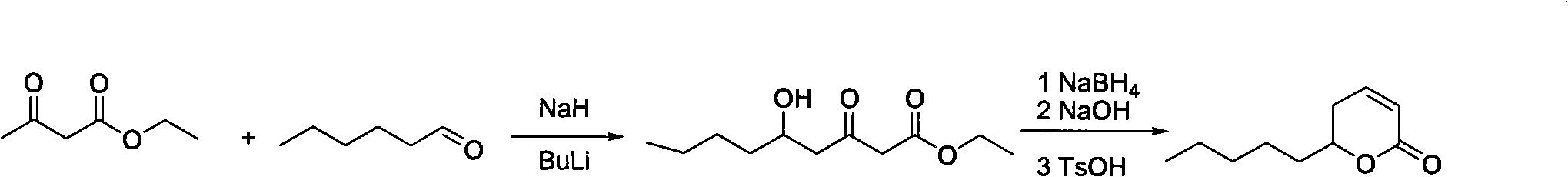

Method used

Image

Examples

Embodiment 1

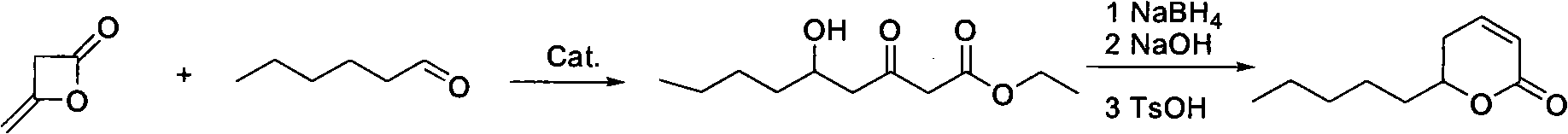

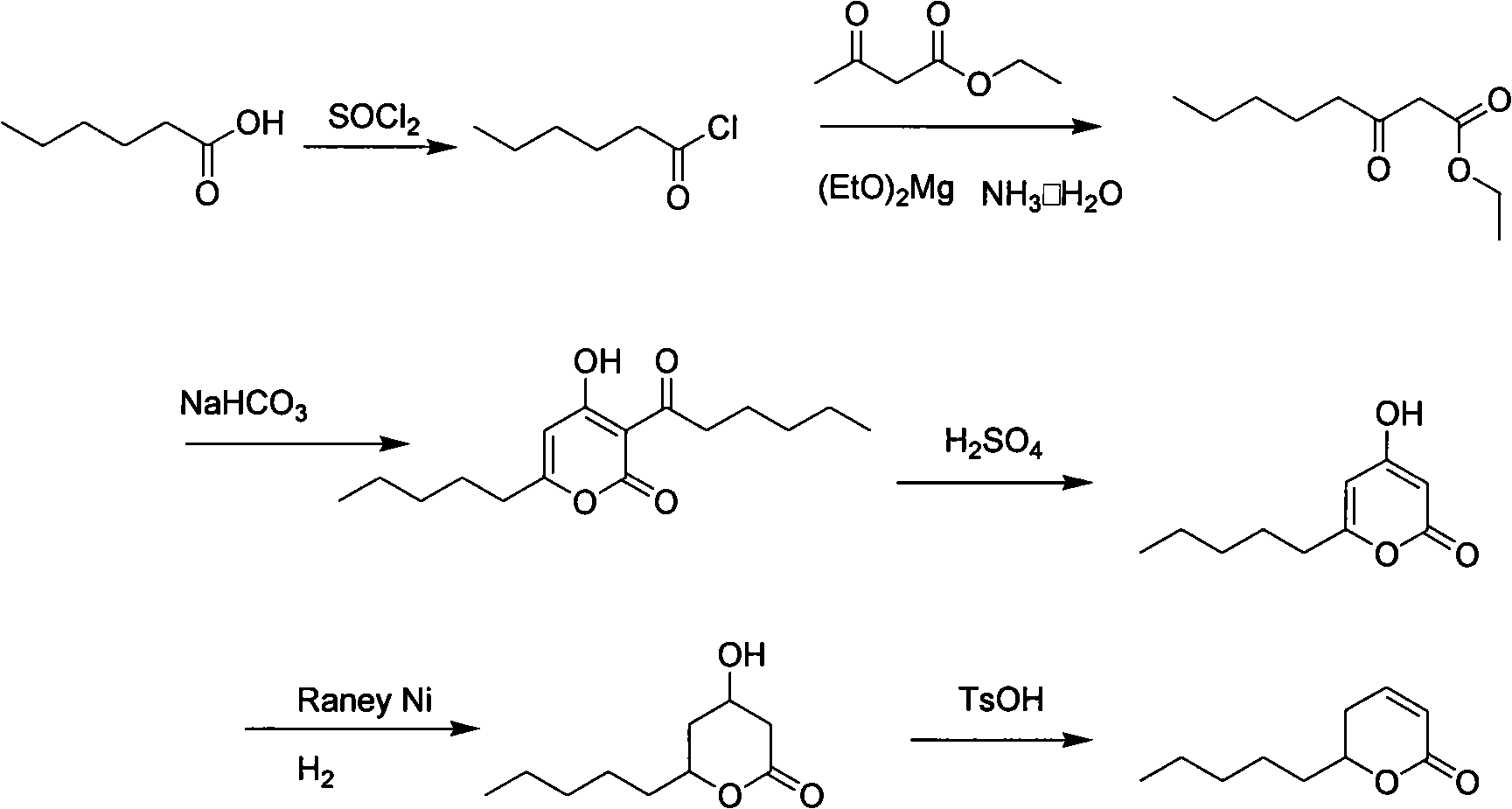

[0029] Step 1: Preparation of Ethyl Hexanoacetate

[0030] In a 5000ml three-neck flask equipped with mechanical stirring, a thermometer and a reflux tube, add 300g of ethyl acetoacetate, 3L of toluene, and 360g of magnesium ethoxide in sequence, react at room temperature for 1 hour, heat to reflux, and slowly add 350g of hexanoyl chloride dropwise for about 2 hours After dripping, add 200ml of 5% HCl after cooling, wash with 50ml of saturated sodium chloride, add 800ml of 25% ammonia water, react at room temperature for 2 hours, separate liquids, wash with dilute hydrochloric acid for 1 hour, wash with saturated sodium chloride, and water. Recover toluene, distill under reduced pressure, collect the components at 87-92 degrees / 1mmHg to obtain ethyl hexanoyl acetate with a yield of 82%.

[0031] Step 2: Preparation of 3-hexanoyl-6-pentyl-2H-pyran-2,4(3H)dione

[0032] Into a 2000mL three-necked flask, add 1000g of ethyl hexanoacetate obtained in step (1), 0.1g of sodium bicar...

Embodiment 2

[0043] Step 1: Preparation of Ethyl Hexanoacetate

[0044]In a 5000ml three-necked flask equipped with mechanical stirring, a thermometer and a reflux tube, add 300g of ethyl acetoacetate, 3L of tetrahydrofuran, and 380g of magnesium ethoxide in sequence, react at room temperature for 1 hour, heat to reflux, and slowly add 350g of hexanoyl chloride dropwise for about 2 hours After dripping, add 200ml of 5% HCl after cooling, wash with 50ml of saturated sodium chloride, then add 1000ml of 25% ammonia water, react at room temperature for 2 hours, separate liquids, wash with dilute hydrochloric acid for 1 hour, wash with saturated sodium chloride, and water. Recover toluene, distill under reduced pressure, collect 87-92 degree / 1mmHg component, yield 80%.

[0045] Step 2: Preparation of 3-hexanoyl-6-pentyl-2H-pyran-2,4(3H)dione

[0046] Add 1000g of ethyl hexanoacetate and 0.05g of sodium bicarbonate to a 2000mL three-necked flask, replace with nitrogen, react in a nitrogen strea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com