Semi-dry salting method for potherb mustard and equipment for salting

A technology for pickled cabbage and equipment, which is applied to the semi-dry pickling method and equipment field of pickled cabbage, can solve the problems of high nitrite content, backward production technology, large amount of wet pickled salt fontanels, etc., and achieves short fermentation time, Easy packaging and transportation, the effect of less salt and brine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

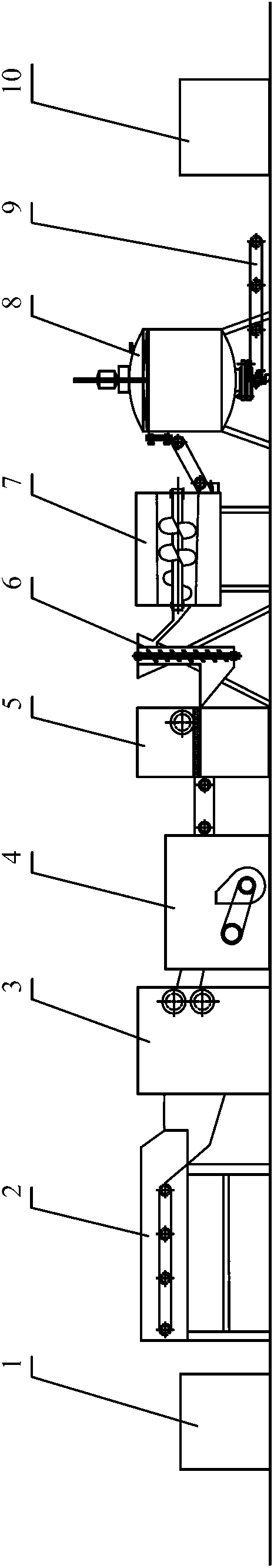

[0042] Example 1, Figure 1~Figure 4 A semi-dry pickling equipment for pickled vegetables is presented, including a cutting machine 3, a washing machine 4, a press 5, a mixer 6, a centrifuge 7 and a fermentation equipment 8 which are connected in sequence; the raw material frame 1 passes through the front conveyor belt 2 and The entrance of the slitting machine 3 is connected. The discharge port 85 of the fermentation device 8 is connected to the finished product basket 10 through the rear conveyor belt 9.

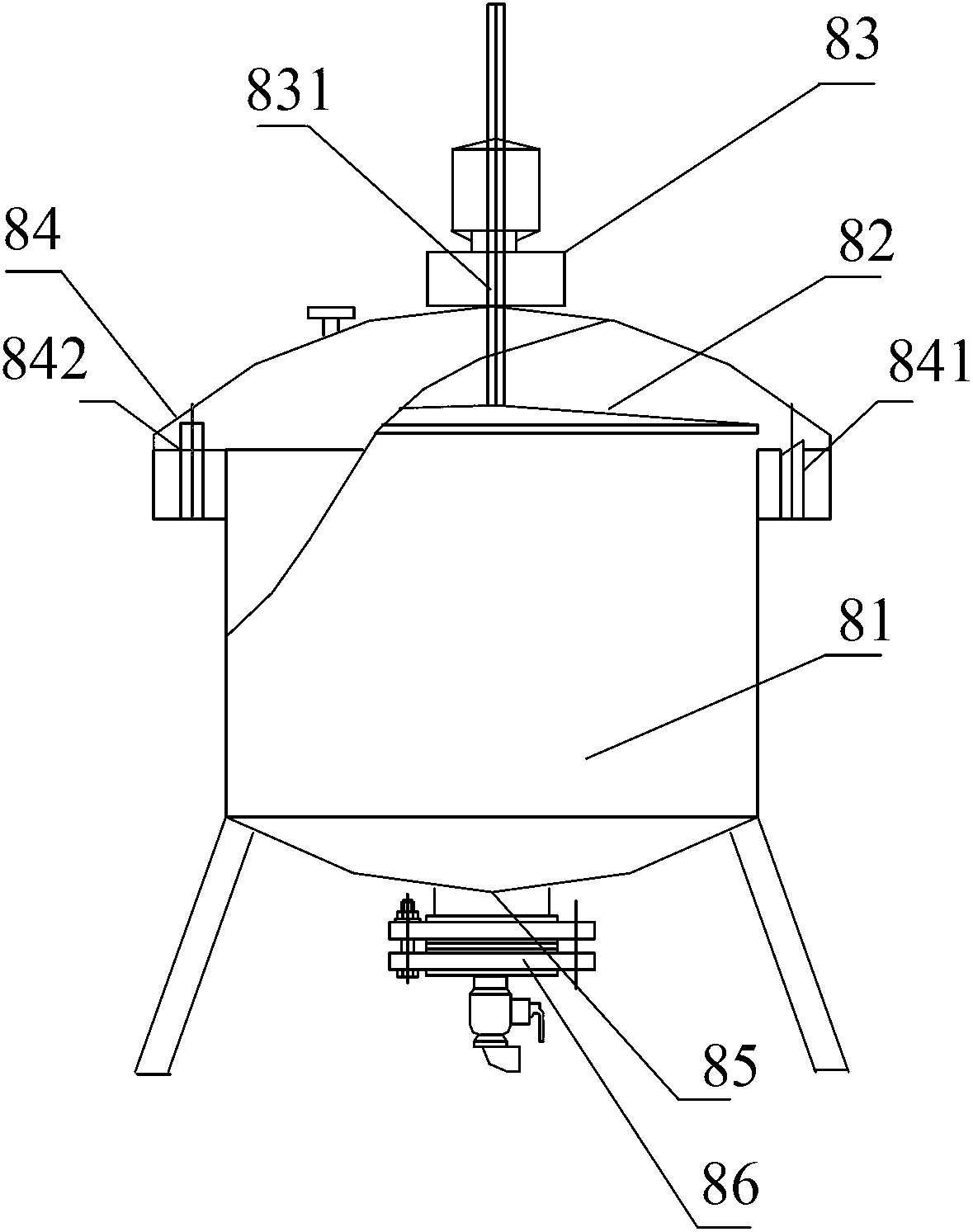

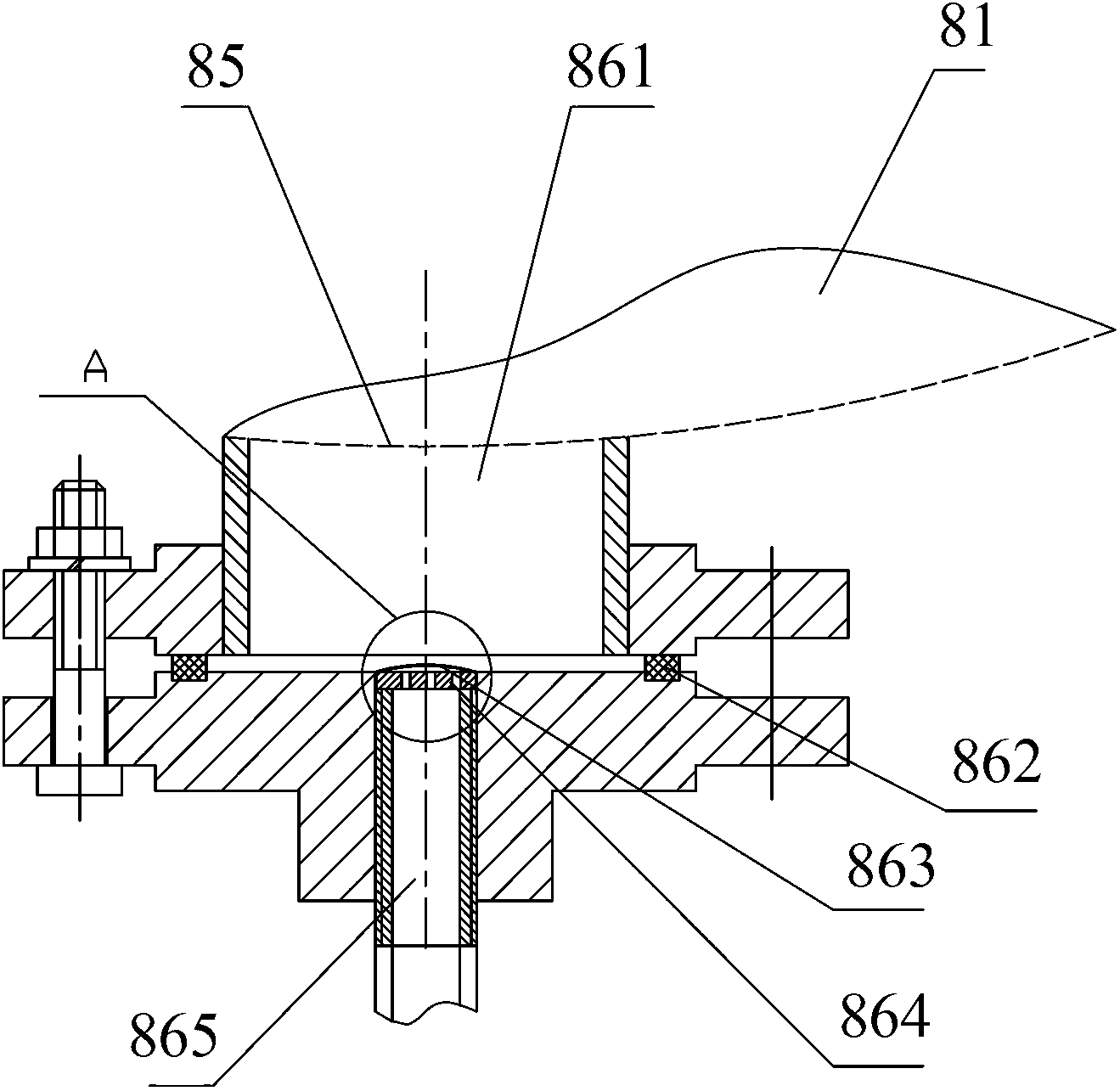

[0043] The fermentation equipment 8 includes a tank-type fermentation chamber 81, which may be made of stainless steel, or may be made of neutral paint such as epoxy resin coated with other metals. An openable top cover 84 is provided on the top of the fermentation chamber 81. For example, the top cover 84 is rotatably connected to the fermentation chamber 81 by a top cover rotating shaft 841. When the top cover 84 rotates to the position of the top cover positioning bayonet...

Embodiment 2

[0057] Embodiment 2. A method for semi-dry pickling of pickled vegetables includes the following steps in sequence:

[0058] 1) Choose high-quality snow vegetable---Zhejiang snow red, and remove impurities on the surface of snow vegetable; 1000 kg of snow vegetable after impurity removal is used as raw material, and packed into raw material box 1.

[0059] 2) The pickled vegetables after removing the impurities enter the slitting machine 3 under the transmission of the front conveyor belt 2, and the slitting machine 3 cuts it into 0.5cm sections; then it is further conveyed to the washing machine 4, the washing machine 4 Wash the above-mentioned segmented pakchoi with clean water to remove the silt entrained in the pakchoi; the washed pakchoi is further conveyed to the press 5, where the gap between the press rolls is adjusted in the press 5, Under the action of the roller, 30% of the water content of the pickled vegetables is removed, and 700 kg of pressed pickled vegetables is ob...

Embodiment 3

[0070] Example 3. In step 2), 30 kilograms of salt and 15 kilograms of chili as a seasoning were respectively mixed in, and the rest were the same as in Example 2.

[0071] In the end, 245 kilograms of pickled pickled vegetables. In the above process, a total of 500 kg of bittern was produced.

[0072] The characteristics of the pickled pickled vegetables are as follows:

[0073] The color is normal, with the inherent aroma of pickled vegetables, moderately salty, sweet and palatable, slightly spicy and refreshing, no peculiar smell, beautiful color matching, no mildew spots, and no impurities. After testing: the salt content is 3.7%, the nitrite content is 1.1mg / kg, the total acid content is 4.0%, and the water content is 74.8%. The product has low salinity and the nitrite content is far below the national standard.

[0074] Comparative test 1-1, using the same 1000 kg of impurity-removed pickled cabbage as the raw material, using the traditional dry pickling method, the required s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com