Material with water-controlled function and preparation method of same

A technology of functional materials and absolute ethanol, which is applied in the field of water-controlling functional materials and its preparation, based on foamed metal water-controlling functional materials and its preparation, can solve the problems that limit the practical application of preparation methods, and achieve good hydrophobic effect and excellent performance. Stable and fast lipophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

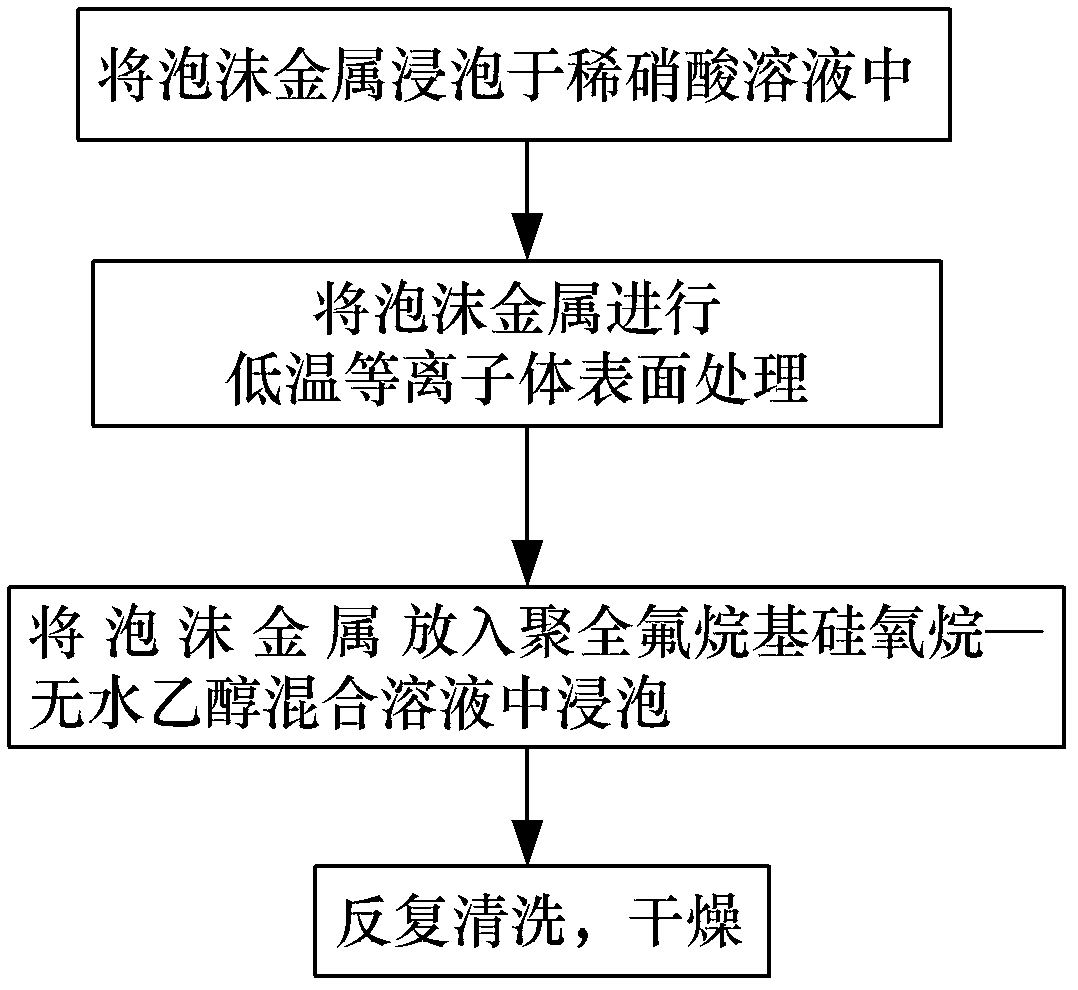

[0045] The preparation method of the water control functional material provided by the present invention can be carried out according to the following steps, and its process is as follows: figure 1 Shown:

[0046] (1) Take a metal foam with a length of 1cm-20cm (preferably 10cm), a width of 1cm-20cm (preferably 5cm), and a thickness of 0.1cm-1cm (preferably 0.2cm), soak it in 100mL-300mL (preferably 200mL) with a mass concentration of 1mol / L-5mol / L (preferably 4mol / L) dilute nitric acid solution, soak for 20 minutes-1 hour (preferably 0.5 hour), take it out, rinse it repeatedly with deionized water 4-5 times, put it in 80℃-110 ℃ (preferably 90 ℃) drying oven ready for use.

[0047] (2) put the metal foam corroded by dilute nitric acid into the reaction chamber of the low-temperature plasma surface treatment instrument and process it twice. The parameters of the first pass treatment are: the vacuum degree of the back and the bottom is 9 Pa-20 Pa (preferably 10 Pa) , high-fr...

Embodiment 1

[0051] This embodiment provides a water control functional material, which is prepared through the following steps:

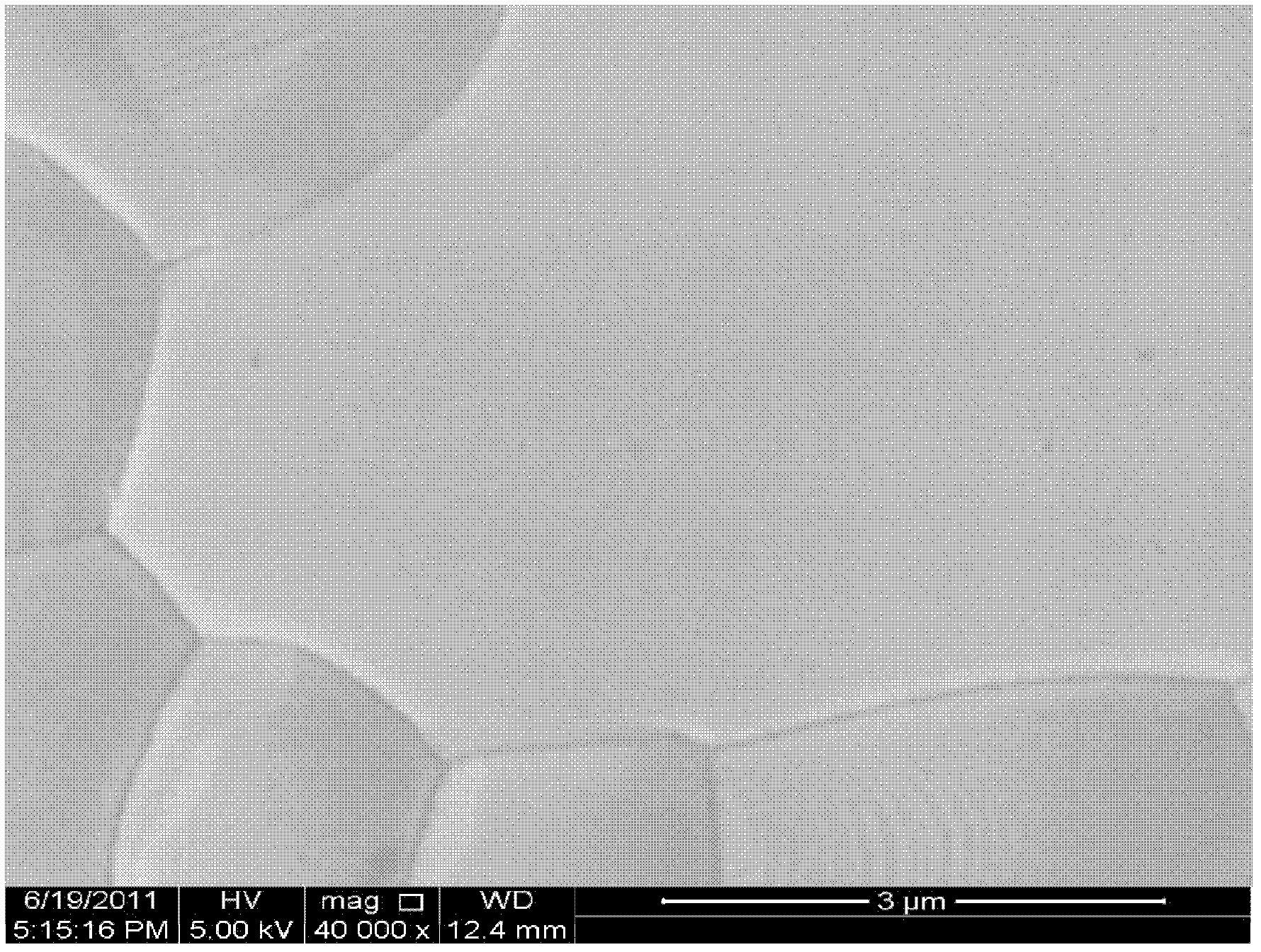

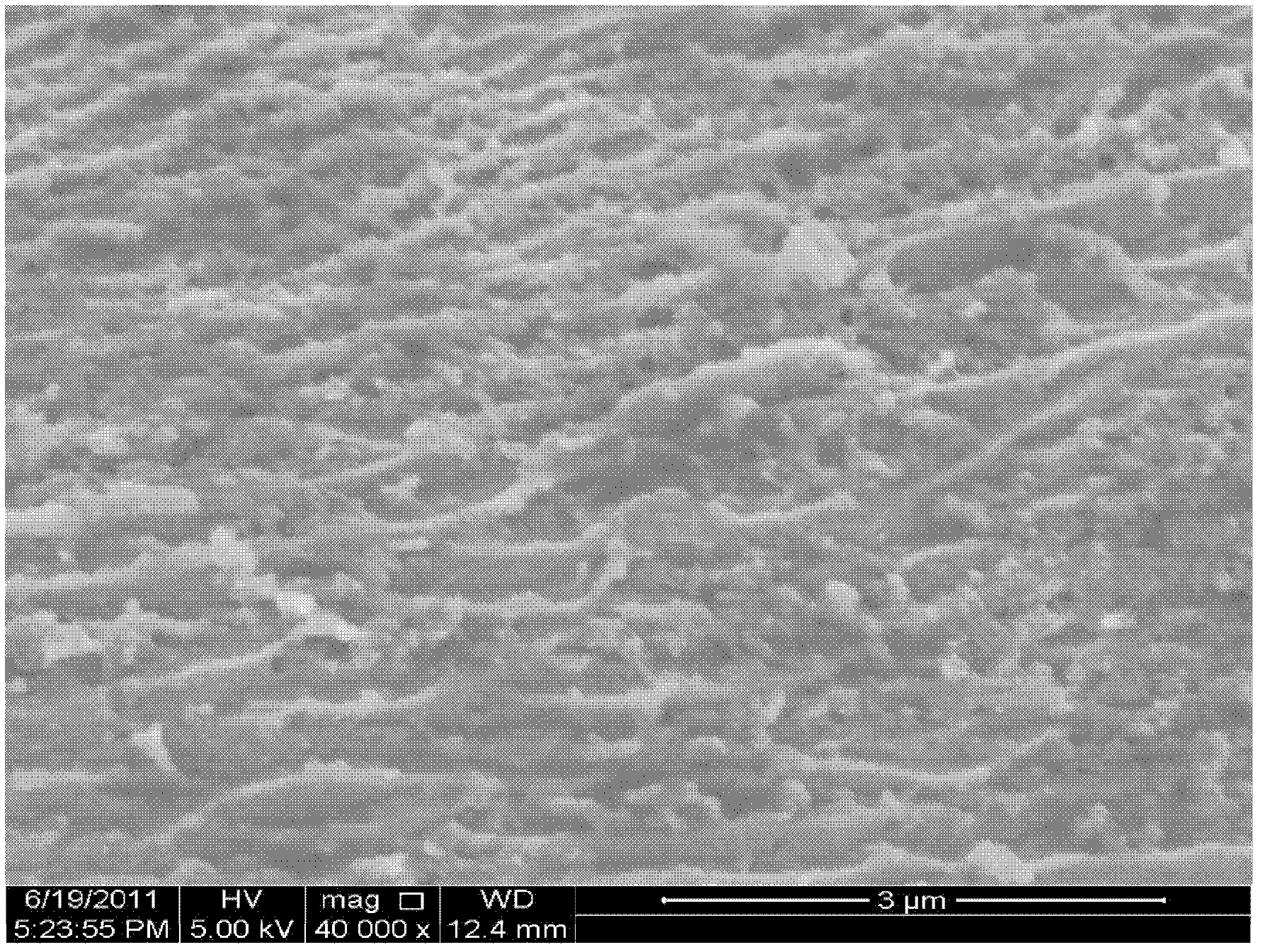

[0052] (1) Take a nickel-based open-cell foam metal with a size of 10cm×10cm×0.5cm, soak it in 100mL of dilute nitric acid solution with a concentration of 1mol / L for 20 minutes, take it out, rinse it repeatedly with deionized water 4-5 times, put Dry it in an oven at 80°C for later use; the electron microscope photo of the open-cell foam metal corroded by dilute nitric acid is as follows: image 3 As shown, it can be observed that the surface of the open-cell metal foam after treatment is relatively rough, which is different from that of the foam metal without dilute nitric acid corrosion treatment (such as figure 2 shown) is significantly different from the smooth surface.

[0053] (2) Put the open-cell foam metal corroded by dilute nitric acid into the reaction chamber of the low-temperature plasma surface treatment instrument for two times of treatment. T...

Embodiment 2

[0057] This embodiment provides a water control functional material, which is prepared through the following steps:

[0058] (1) Take a nickel-based open-cell foam metal with a size of 20cm×10cm×0.5cm, soak it in 300mL of dilute nitric acid solution with a concentration of 5mol / L for 1 hour, take it out, rinse it repeatedly with deionized water 4-5 times, Dry it in an oven at 110°C.

[0059] (2) Put the open-cell foam metal corroded by dilute nitric acid into the reaction chamber of the low-temperature plasma surface treatment instrument for two times of treatment. The parameters of the first treatment are: the vacuum degree of the back and bottom is 20 Pa, and the high-frequency power is 300 watts. , the discharge time is 1000 seconds; the parameters of the second pass are: the back vacuum is 20 Pa, the high-frequency power is 180 watts, and the discharge time is 1000 seconds.

[0060] (3) Take out the open-cell foam metal treated with low-temperature plasma, put it into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com