Highly adhesive thermoplastic polyimide resin, polyimide film containing same, and flexible copper clad plate

A technology of polyimide resin and polyimide film, which is applied in the fields of polyimide film, flexible copper clad laminate, and high-adhesive thermoplastic polyimide resin, which can solve the problem of increased product cost and mechanical properties of TPI film. Reduce problems such as improving peel strength, increasing surface roughness, and strong bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

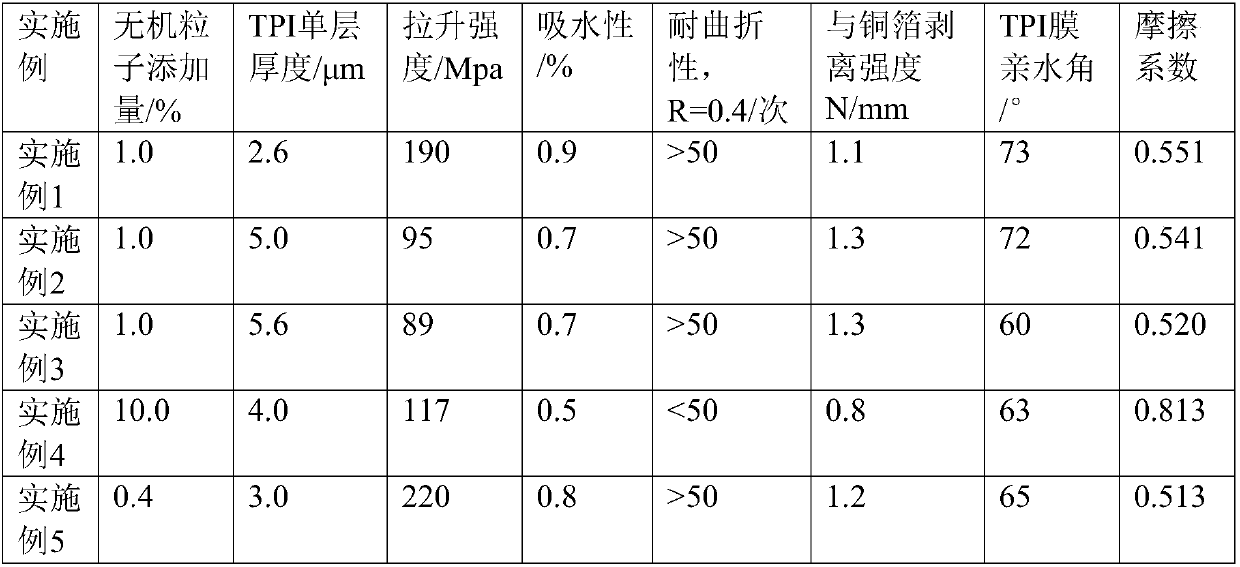

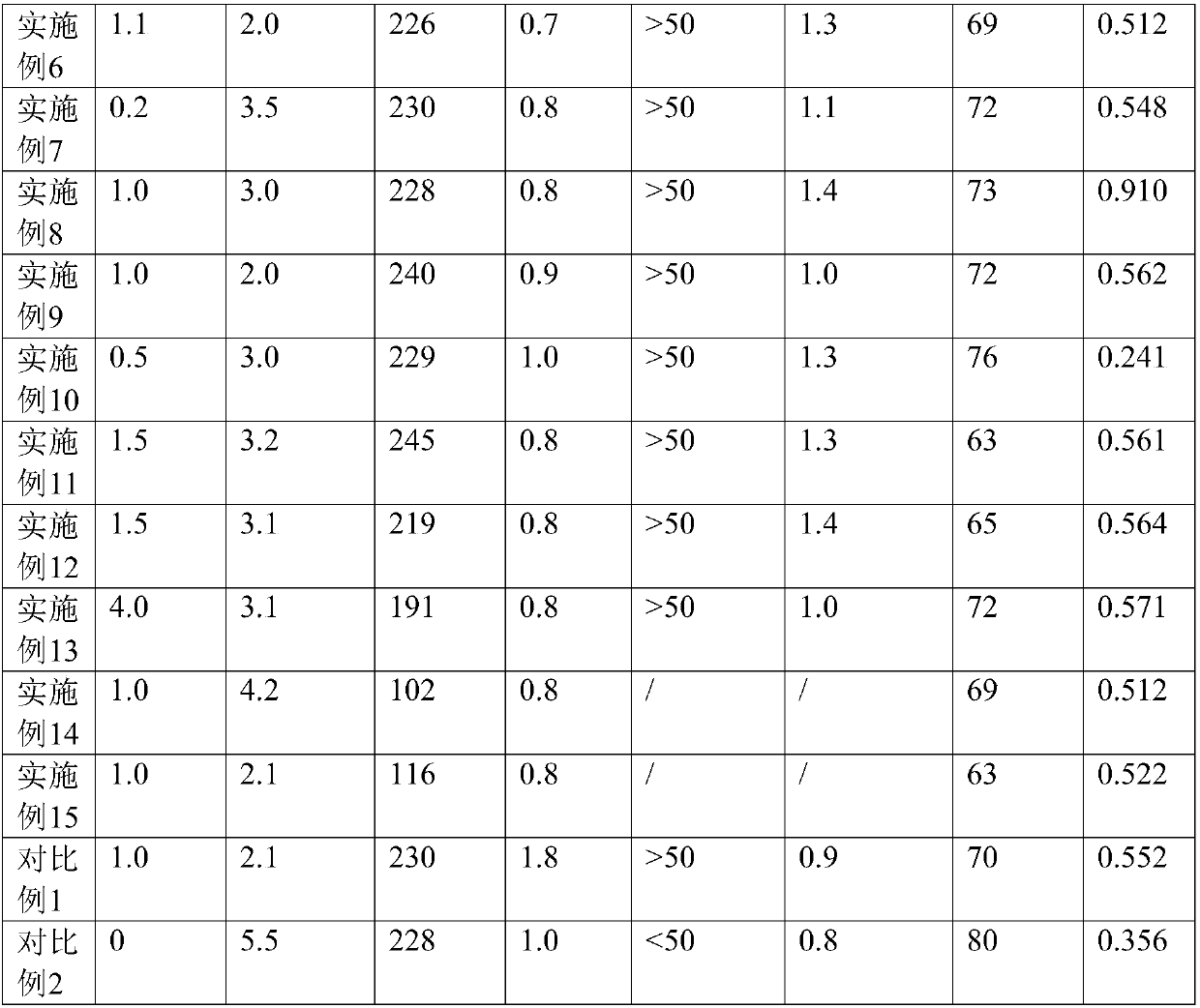

Examples

Embodiment 1

[0029] 1. Synthesis of high adhesive TPI resin

[0030] Step 1: Add 1.0 parts of 2-3 μm flakes to 399 parts of N,N-dimethylacetamide, and stir mechanically for 2 hours to obtain an inorganic dispersion;

[0031] Step 2: Add 20.249 parts of 4,4-diaminodiphenyl ether and 20.249 parts of 3,4-diaminodiphenyl ether to the inorganic dispersion prepared in step 1, stir and dissolve for 30 minutes, and add 59.523 parts in 6 times Parts of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride, and each time at an interval of 30min, and finally stirred for 4h to obtain a high-adhesive TPI resin (resin solid content is 20w / w%, Inorganic particles / resin 1.0 w / w%).

[0032] 2.2 L-FCCL preparation

[0033]Step 1: Coat the high-adhesive TPI resin synthesized in the previous step 2 on the PI film with a thickness of 12.5 μm and high dimensional stability produced by Kaneka Company in Japan, and pass 80°C / 30min→140°C / 30min→190°C / 30min→240°C / 30min→290°C / 30min→320°C / 30min degree of thermal im...

Embodiment 2

[0037] 1. Synthesis of PI resin with high dimensional stability

[0038] At room temperature, dissolve 23.932 parts of 4,4-diaminodiphenyl ether in 450 parts of N,N-dimethylacetamide, stir and dissolve for 30 minutes, add 4,4-diaminodiphenyl ether in 5 times 26.086 parts of pyromellitic dianhydride in an equimolar amount of diphenyl ether were stirred and reacted for 6 hours to prepare a PI resin with high dimensional stability (solid content: 10w / w%).

[0039] 2. Synthesis of high adhesive TPI resin

[0040] The preparation method is the same as in Example 1.

[0041] 3. Preparation of flexible copper clad laminate

[0042] Step 1: Scrape-coat the above-mentioned synthetic high-dimensionally stable PI resin on a smooth glass plate, and pass 80°C / 30min→140°C / 30min→190°C / 30min→240°C / 30min→290°C / 30min→320°C / 30min Degree of thermal imidization to obtain a PI film with high dimensional stability; then coat the high-adhesive TPI resin synthesized above on the PI film with high d...

Embodiment 3

[0046] 1. Synthesis of PI resin with high dimensional stability

[0047] At room temperature, 26.892 parts of 4,4-diaminodiphenyl ether and 14.523 parts of p-phenylenediamine were dissolved in 400 parts of N,N-dimethylpyrrolidone, stirred and dissolved for 30 minutes, and added in 5 times with two 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride in an equimolar amount of amine, and stirred for 6 hours to prepare a PI resin with high dimensional stability (solid content: 20w / w%).

[0048] 2. Synthesis of high adhesive TPI resin

[0049] The preparation method is the same as in Example 1.

[0050] 3. Preparation of flexible copper clad laminate

[0051] Step 1: Scrape-coat the above-mentioned synthetic high-dimensionally stable PI resin on a smooth glass plate, and dry it at 80°C / 30min→140°C / 30min to obtain a self-supporting PI film; then apply the above-mentioned synthetic high-adhesive The permanent TPI resin is coated on the PI base film with high dimensional stability...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com