Desulfurization and combustion method using calcium carbide slurry and coal slurry in thermal power plant

A combustion method and calcium carbide mud technology, which are applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of high cost of desulfurization technology and difficult by-product treatment, so as to overcome the difficulty of by-product treatment and achieve good sulfur fixation effect. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

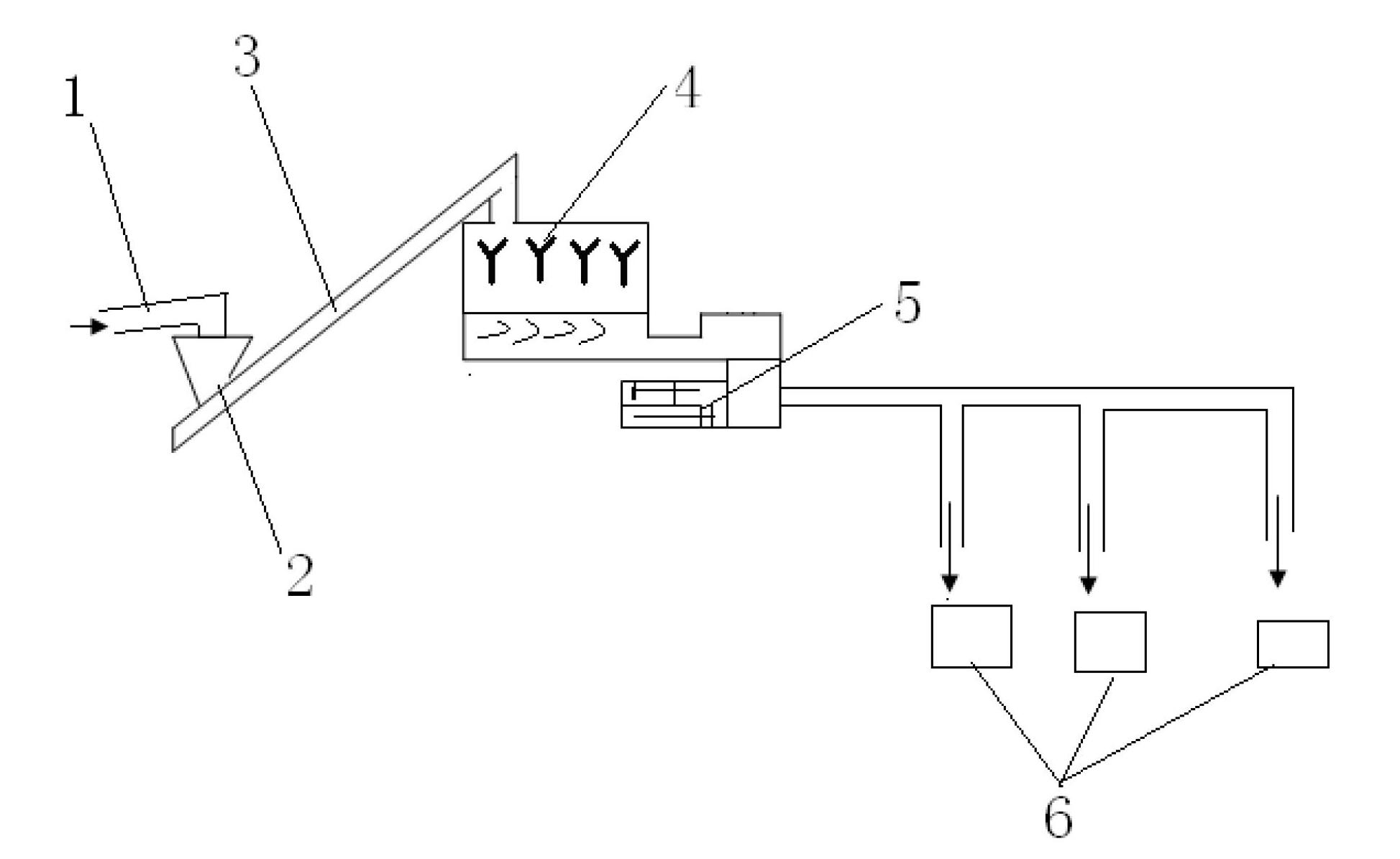

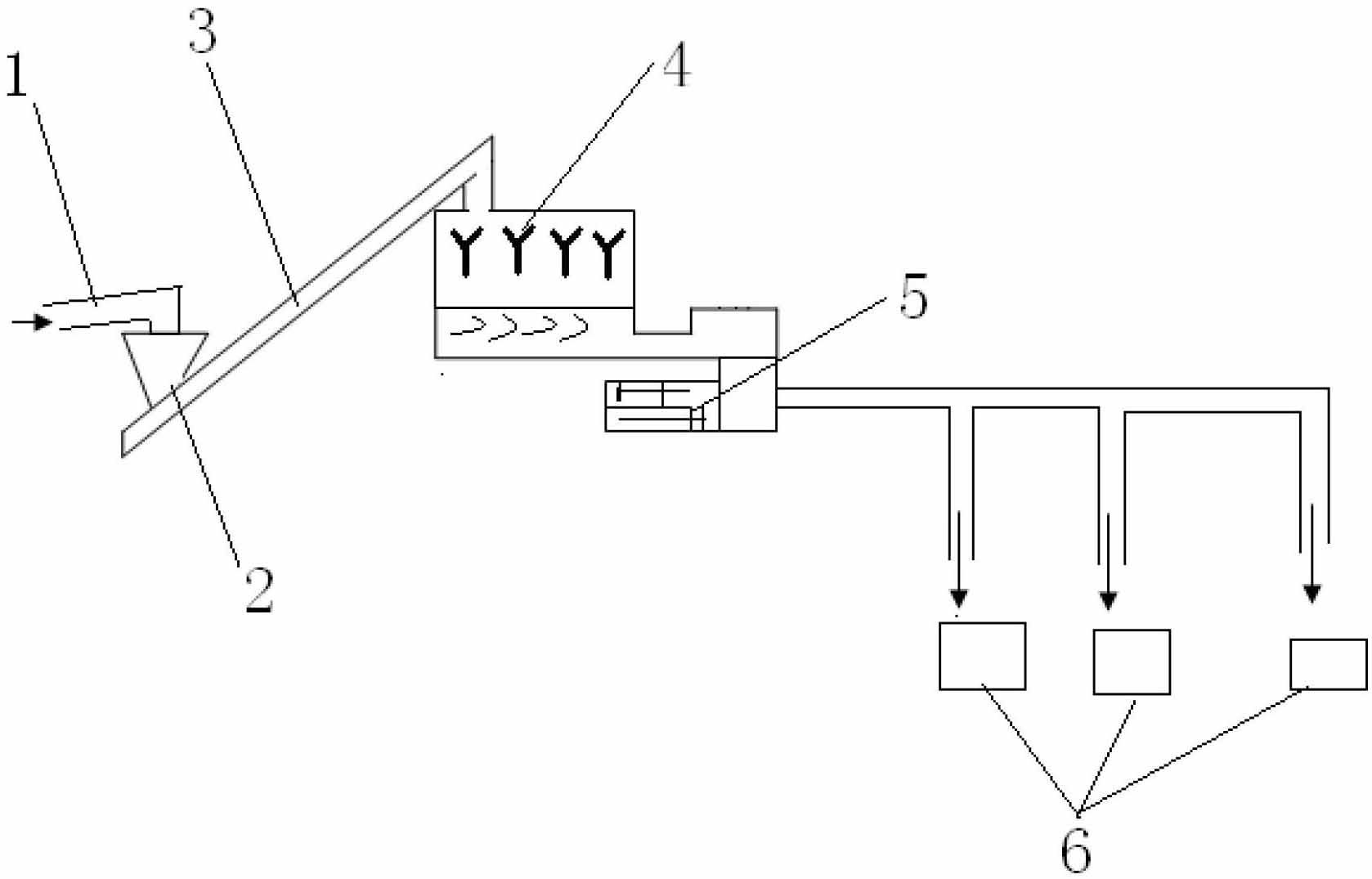

[0012] The desulfurization combustion method of the present invention will be further described below according to the accompanying drawings.

[0013] Such as figure 1 As shown, calcium carbide mud and coal slime enter the bin 2 through the scraper conveyor 1 according to the required ratio, and carry out preliminary mixing and mixing in the bin 2. After mixing, they are sent to the mixing bin 4 by the pre-pressing screw feeding device 3. The material in the mixing chamber 4 is stirred again, and then sent to the circulating fluidized bed boiler 6 by the concentrated material pump 5 for mixed deflagration to achieve the effect of desulfurization.

[0014] The pre-pressing screw feeding device of the present invention is existing commercially available equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com