Preparation of tellurate series glass with large stimulated emission section and high thermal stability

A high thermal stability, stimulated emission technology, applied in the field of optical materials, can solve the problems of less than ideal thermal stability and chemical stability, less thermal performance and high gain performance of laser glass, poor thermal stability against devitrification, etc. Achieve the effect of low phonon energy, wide fluorescence linewidth, and high thermal stability parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the above-mentioned tellurite-based glass includes the following process:

[0043] Use an alumina crucible to feed materials at 750°C-820°C, among which 800°C is the best; then, raise the temperature to 900°C-950°C to form the material; after the material is melted, stir once with a quartz rod to make the glass liquid uniform; after 20 minutes, the second Secondary stirring; heat preservation at 900°C-950°C for 10 minutes and release from the oven. Pour the molten glass on the preheated copper mold, and quickly move it into the annealing furnace after forming, and perform precision annealing at the glass transition temperature, the annealing rate is 2°C / min-3°C / min, until it cools to room temperature.

Embodiment 1

[0045] The composition of the glass is: TeO 2 : 66 mol%, Nb 2 o 5 : 10 mol%, ZnO: 18 mol%, PbF 2 : 2 mol%, ZrF 4 : 3mol%, Yb 2 o 3 : 1 mol%, and the purity of the raw materials is 4N and above. Accurately calculate, weigh and shake according to the formula.

[0046] In the experiment, alumina crucible was used to feed materials at 750°C; then, the temperature was raised to 900°C to form the materials; after 15 minutes, the materials were stirred once with a quartz rod to make the glass liquid uniform; after 20 minutes, the second stirring was carried out; , out of the oven. Pour the molten glass onto the preheated copper mold, move it into the annealing furnace quickly after forming, and anneal at the glass transition temperature for 6 hours, then cool naturally to room temperature.

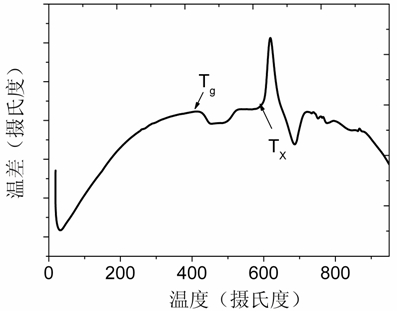

[0047] The DSC curve of the sample prepared by embodiment 1 is shown in figure 1 , its glass transition temperature is 406 (± 5 ℃) ℃, the crystallization start temperature is 592 ℃, and...

Embodiment 2

[0049] The composition of the glass is: TeO 2 : 66 mol%, Nb 2 o 5 : 10 mol%, ZnO: 14 mol%, PbF 2 : 6 mol%, ZrF 4 : 3mol%, Yb 2 o 3 : 1 mol%, and the purity of the raw materials is 4N and above. Accurately calculate, weigh and shake according to the formula.

[0050] In the experiment, alumina crucible was used to feed materials at 750°C; then, the temperature was raised to about 900°C to form the materials; after 10 minutes, the materials were stirred once with a quartz rod to make the glass liquid uniform; after 15 minutes, the second stirring was carried out; , out of the oven. Pour the molten glass onto the preheated copper mold, move it into the annealing furnace quickly after forming, and anneal at the glass transition temperature for 6 hours, then cool naturally to room temperature.

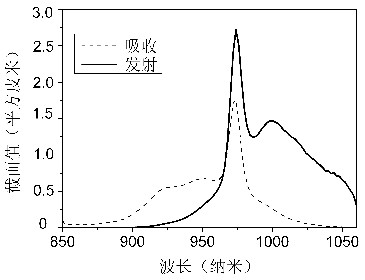

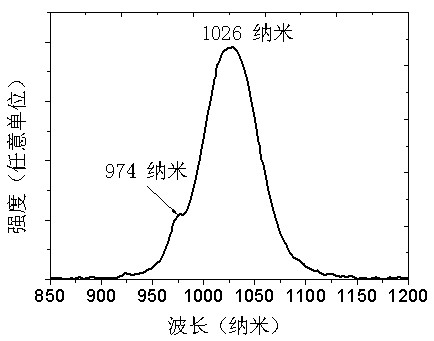

[0051] The absorption cross section and the stimulated emission cross section diagram of the sample prepared in embodiment 2 are shown in figure 2 shown. The glass has a subpeak ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com