Extracting method of lonicera caerulea anthocyanidin

An extraction method, the technology of cyanide fruit, applied in the direction of chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of low extraction rate and low activity of cyanide anthocyanins, and achieve good drug efficacy and activity Strong and suitable for promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

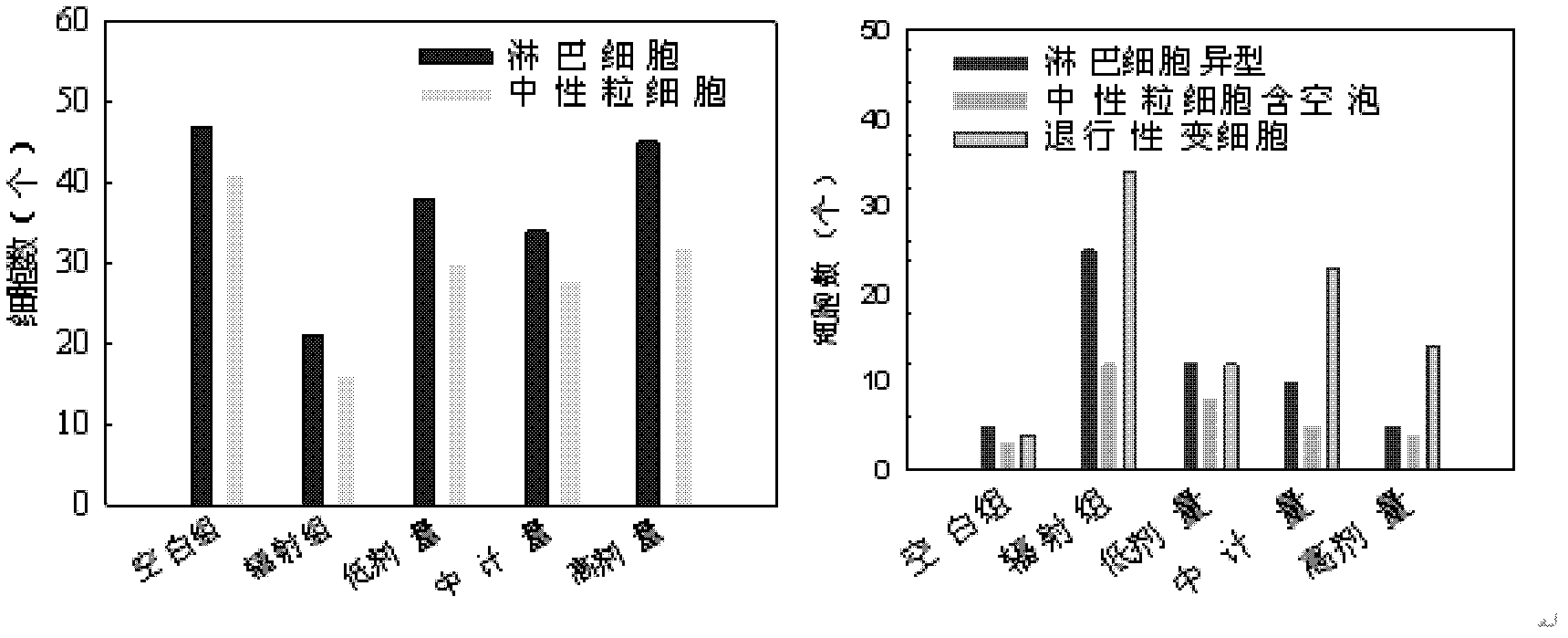

Image

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: in the present embodiment, the extraction method step of indigo anthocyanin is as follows:

[0014] 1. Preparation of the crude extract of indigo anthocyanins: Weigh the frozen fresh fruit, add ethanol with a volume concentration of 60-80% at a ratio of 1kg: 2-4L solid-liquid, squeeze the juice and homogenate for 3 minutes, homogenize at 16000 rpm For 3 minutes, use a decanter centrifuge to separate the solid and liquid at a speed of 1500-2000r / min, separate the extract and residue, add the residue to the aqueous solution at a ratio of 1kg: 2-4L, and continue the low-temperature process. Homogeneous extraction and centrifugation, continuous extraction 3 times, remove the residue, and combine the extracts.

[0015] 2. Concentration: Concentrate the extract of indigo anthocyanin with a vacuum scraper film, the concentration condition is 45-50° C., and the vacuum degree is 0.1-0.15 mbar to obtain the concentrated solution of indigo anthocyanin, and...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that in Step 1, the speed of the high-speed homogenizer is 16,000-24,000 rpm, the extraction time is 3-10 minutes, and the ethanol concentration is 60-80%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment is different from Embodiment 1 and Embodiment 2 in that: the vacuum degree of the vacuum concentration process in step 2 is lower than 0.09Mpa, and the temperature is 35-45°C. Others are the same as the specific embodiment 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com