High-efficiency extraction and cleaning production process for diosgenin

A technology of diosgenin and production process is applied in the field of efficient extraction of diosgenin and clean production technology, can solve the problems of low extraction efficiency, high production cost, environmental pollution and the like, and achieves the effect of high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

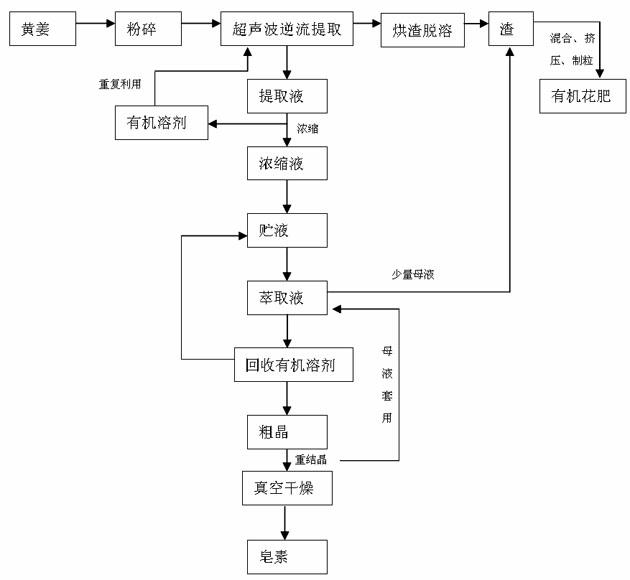

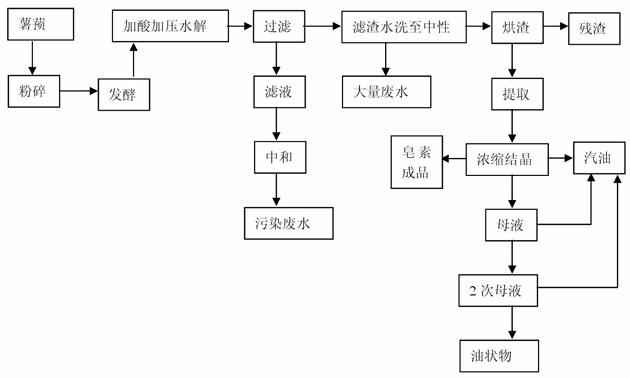

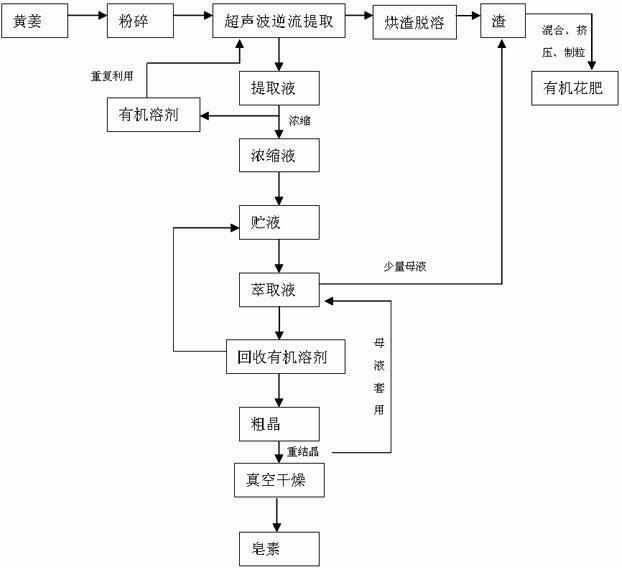

Method used

Image

Examples

Embodiment 1

[0038] Take 100kg of dry yam (containing about 2% diosgenin), crush it, pass it through a 10-mesh sieve, and use methanol solvent for ultrasonic continuous countercurrent extraction at a frequency of 25 Hz. The filter residue is used as bio-organic fertilizer, and the filtrate is concentrated. Put the concentrated solution into a pressurized hydrolysis tank, add hydrochloric acid to make the concentration 2mol / L, and perform enzymatic hydrolysis at 90°C for 5 hours. Filtration, drying, continuous countercurrent extraction with 120# gasoline of 8 times the liquid volume of the enzymatic hydrolyzate, cooling and crystallization of the extract after concentration, suction filtration, and drying to obtain 99.25% pure diosgenin with a melting point above 195.5°C.

Embodiment 2

[0040] Take 200kg of dry yam (containing about 2% diosgenin), crush it, pass through a 20-mesh sieve, and use ethanol solvent ultrasonic continuous countercurrent extraction at a frequency of 35Hz. The filter residue is used as bio-organic fertilizer, and the filtrate is concentrated. Put the concentrated solution into an atmospheric pressure hydrolysis tank, add hydrochloric acid to make the concentration 2mol / L, and hydrolyze at 90°C for 5 hours. Filter and adjust the pH of the hydrolyzate to neutral. The neutralized hydrolyzate was continuously extracted with 5 times the amount of liquid 120# gasoline, the extract was concentrated to a small volume, cooled and crystallized, suction filtered, and dried to obtain 98.5% pure diosgenin with a melting point of 195°C above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com