Temperature sensitive type microgel modified by L-amino acid

A microgel and amino acid technology, applied in the field of temperature-sensitive polymer materials, can solve the problems of slow reaction, high substrate requirements, and high product cost, and achieve the effects of stable molecular structure, simple operation, and controllable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

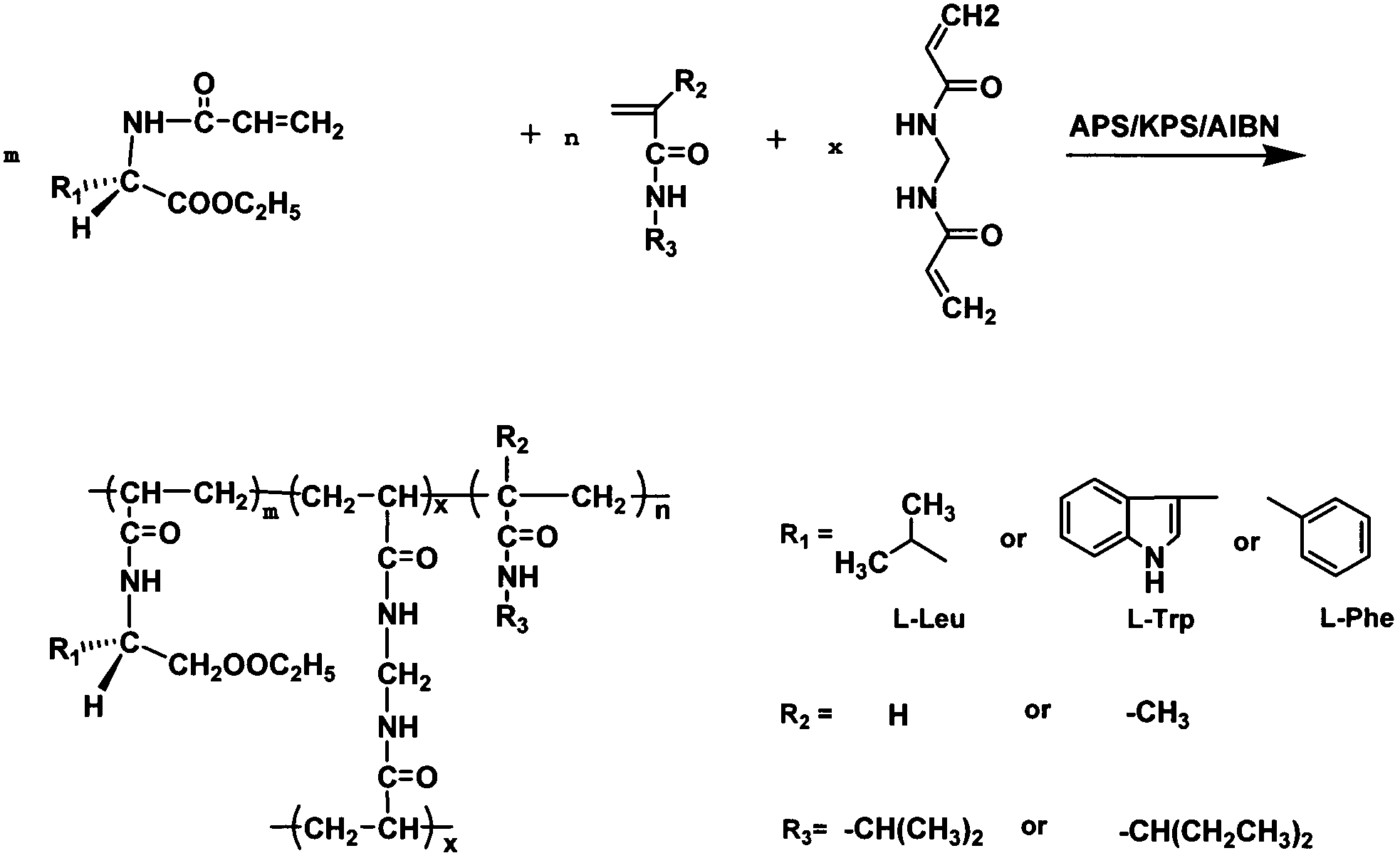

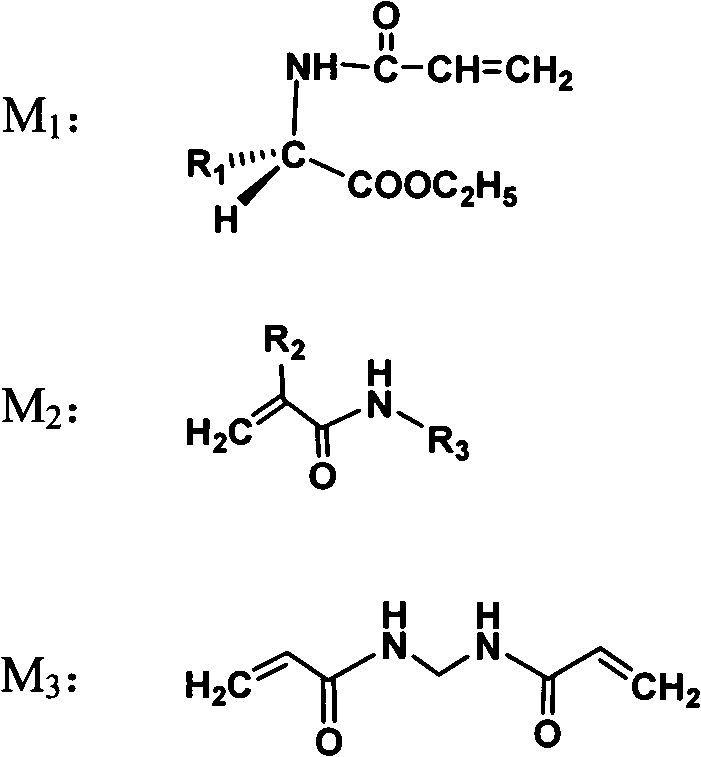

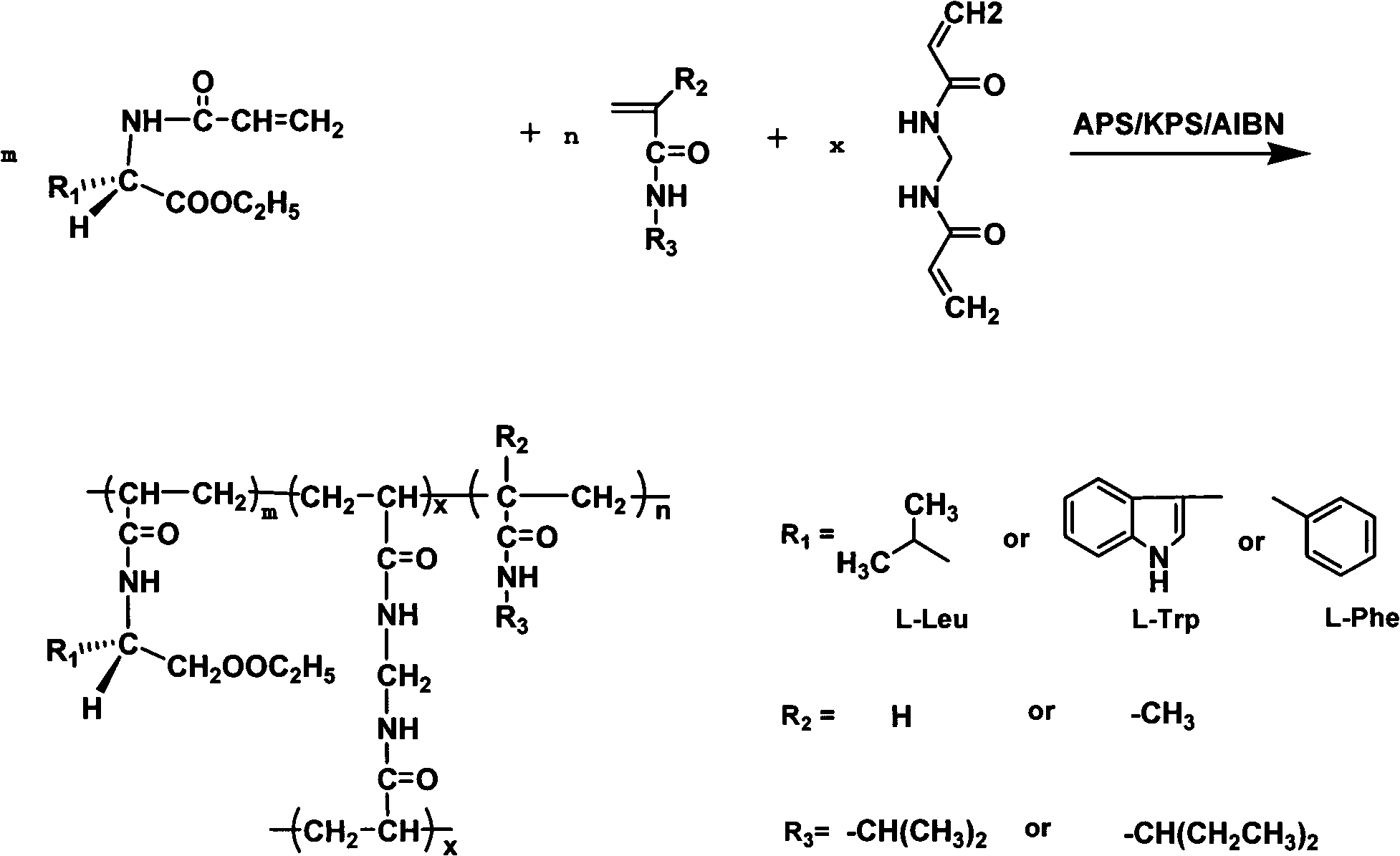

Method used

Image

Examples

Embodiment 1

[0023]Dissolve 1.00g of N-isopropylacrylamide (NIPAM) and 0.10g of MBA in 150mL of deionized water and stir until the solution is transparent, then transfer it into a 250mL four-neck flask equipped with a condenser, a constant pressure dropping funnel, a thermometer and a nitrogen inlet . Under low-speed stirring, pass nitrogen gas to remove oxygen for 30 minutes, raise the temperature to 70°C, keep the temperature for 30 minutes, add 5 mL of APS aqueous solution with a mass concentration of 0.5%, and drop it within 5 minutes. After 5 minutes, the system slowly turns milky white. Nitrogen was continuously passed during the reaction. After the reaction, it was naturally cooled to room temperature. Centrifuge the obtained microgel emulsion, redisperse the microgel in deionized water with ultrasonic oscillation, and centrifuge again, and repeat this three times to remove residual monomers and cross-linking agents, etc., and then put it in a freeze dryer Dry in medium temperatur...

Embodiment 2

[0026] Dissolve the chiral monomer AAc-L-Phe 0.05g, 0.95g NIPAM and 0.10gMBA in 150mL of deionized water and stir until the solution is transparent, then transfer it into a 250mL four-phase tank equipped with a condenser, a constant pressure dropping funnel, a thermometer and a nitrogen inlet. mouth flask. Under low-speed stirring, pass nitrogen gas to remove oxygen for 30 minutes, raise the temperature to 70 ° C, keep the temperature for 30 minutes, add 5 mL of APS aqueous solution with a mass concentration of 0.5%, and drop it within 5 minutes. Nitrogen was continuously passed through during the process. After the reaction, it was naturally cooled to room temperature. Centrifuge the obtained microgel emulsion, redisperse the microgel in deionized water with ultrasonic oscillation, and centrifuge again, and repeat this three times to remove residual monomers and cross-linking agents, etc., and then put it in a freeze dryer Dry in medium temperature, take out after 24 hours ...

Embodiment 3

[0029] Dissolve the chiral monomer AAc-L-Phe 0.10g, 0.90g NIPAM and 0.10gMBA in 150mL of deionized water and stir until the solution is transparent, then transfer it into a 250mL four-phase tank equipped with a condenser, a constant pressure dropping funnel, a thermometer and a nitrogen inlet. mouth flask. Under low-speed stirring, pass nitrogen gas to remove oxygen for 30 minutes, raise the temperature to 70 ° C, keep the temperature for 30 minutes, add 5 mL of APS aqueous solution with a mass concentration of 0.5%, and drop it within 5 minutes. Nitrogen was continuously passed through during the process. After the reaction, it was naturally cooled to room temperature. Centrifuge the obtained microgel emulsion, redisperse the microgel in deionized water with ultrasonic oscillation, and centrifuge again, and repeat this three times to remove residual monomers and cross-linking agents, etc., and then put it in a freeze dryer Dry in medium temperature, take out after 24 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com