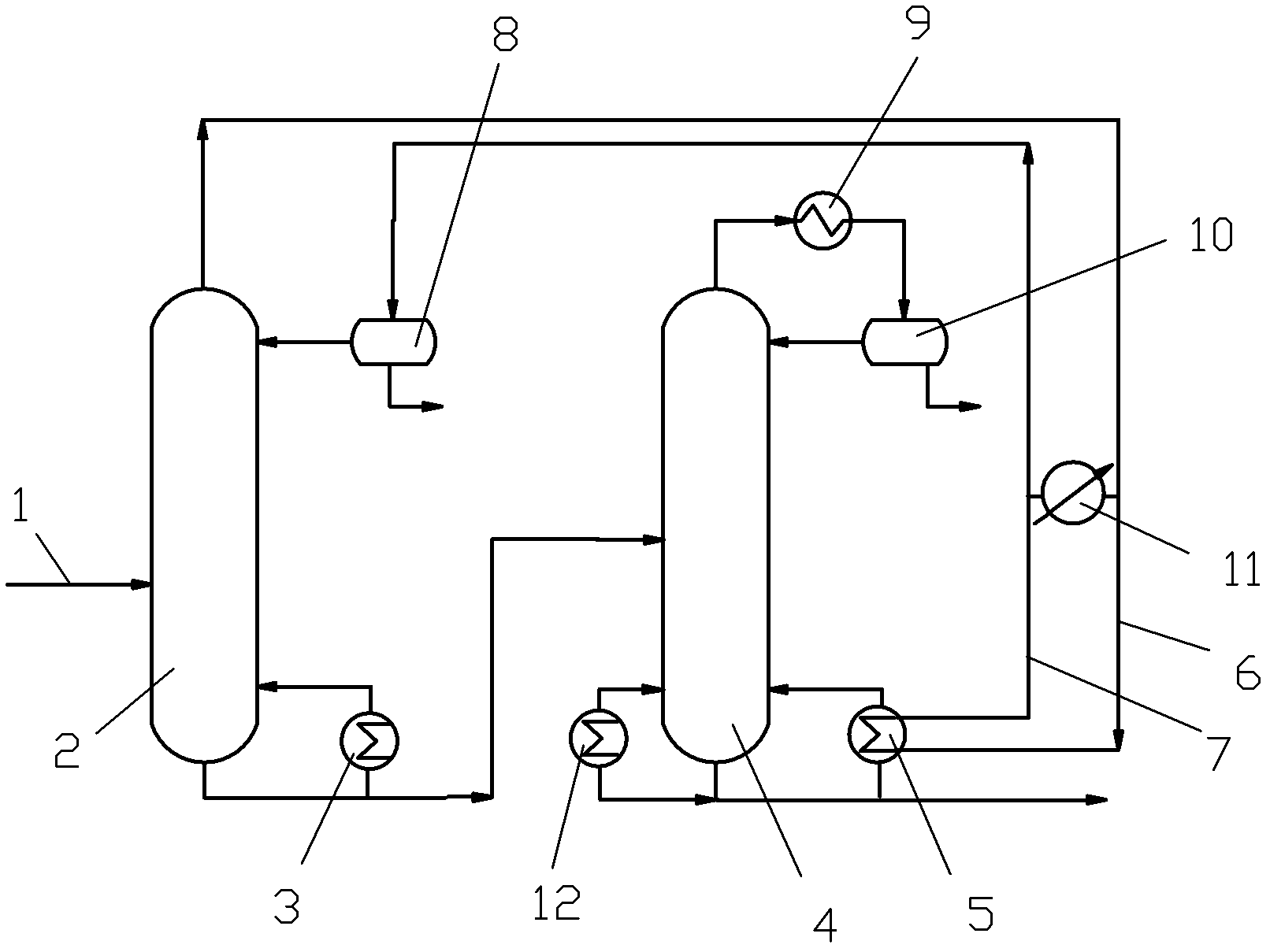

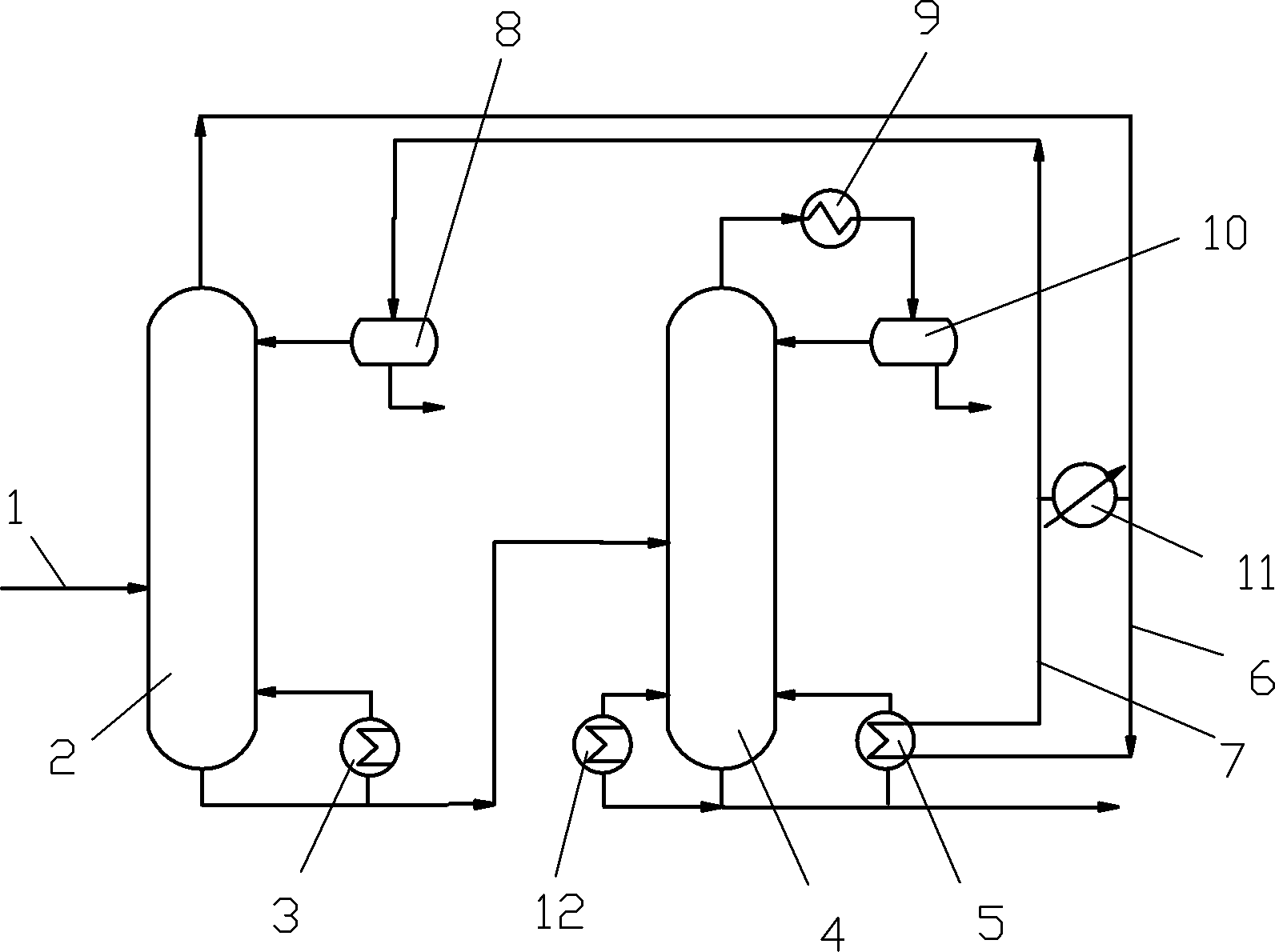

Thermal coupling method for preparing solvent naphtha from C9 resin flash oil

A solvent oil and flash oil technology, used in hydrocarbon distillation, petroleum industry, etc., can solve the problems of complex components, unsuitable single component, and many active components, and achieve simple process operation, increase added value, and process flow. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Will C 9 Resin flash oil is sent to 150# solvent oil rectifying tower, feed rate 100kg / hr, tower top pressure is 50kPa, tower top temperature is 120 ℃, obtains the 150# solvent oil that final boiling point is 150 ℃ by tower top; The pressure at the top of the 180# solvent oil rectifying tower is 5kPa, the temperature at the bottom of the tower is 105°C, and the 180# solvent oil with a final boiling point of 180°C is obtained from the top of the tower. The operating pressure of the 150# solvent oil rectification tower is higher than that of the 180# solvent oil rectification tower, so that the temperature of the reboiled material in the 180# solvent oil rectification tower is lower than that of the top material of the 150# solvent oil rectification tower Therefore, the matching heat exchange of the two materials can be used to realize the thermal coupling of the two towers. In this embodiment, the heat provided by condensation at the top of the 150# solvent oil rectific...

Embodiment 2

[0025] Will C 9 Resin flash oil is sent to 150# solvent oil rectifying tower, feed rate 150kg / hr, tower top pressure is 101kPa, and tower top temperature is 142 ℃, obtains the 150# solvent oil that final boiling point is 150 ℃ by tower top; The pressure at the top of the 180# solvent oil rectifying tower is 20kPa, the temperature at the bottom of the tower is 120°C, and the 180# solvent oil whose final boiling point is 180°C is obtained from the top of the tower. The operating pressure of the 150# solvent oil rectification tower is higher than that of the 180# solvent oil rectification tower, so that the temperature of the reboiled material in the 180# solvent oil rectification tower is lower than that of the top material of the 150# solvent oil rectification tower Therefore, the thermal coupling of the two towers is realized by using the matched heat exchange of the two materials. In this embodiment, the heat provided by condensation at the top of the 150# solvent oil rectif...

Embodiment 3

[0027] According to the above technical scheme, the C 9Resin flash oil is sent to 150# solvent oil rectifying tower, feed rate 200kg / hr, tower top pressure is 150kPa, and tower top temperature is 160 ℃, obtains the 150# solvent oil that terminal boiling point is 150 ℃ by tower top; The pressure at the top of the 180# solvent oil rectifying tower is 30kPa, and the temperature at the bottom of the tower is 140°C, and the 180# solvent oil whose final boiling point is 180°C is obtained from the top of the tower. In this embodiment, the heat provided by condensation at the top of the 150# solvent oil rectifying tower fully matches the heat required for the rising and reboiling steam at the bottom of the 180# solvent oil rectifying tower, without opening the auxiliary condenser or auxiliary reboiler. The heating energy consumption is reduced by 44.7% compared with the conventional heat-free coupling rectification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com