Preparation method for ZnO/ZnS heterostructure nanocone array

A heterostructure and nano-cone technology, applied in the manufacture of discharge tubes/lamps, microstructure technology, microstructure devices, etc., can solve problems such as unsatisfactory field emission performance, high turn-on electric field and threshold electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

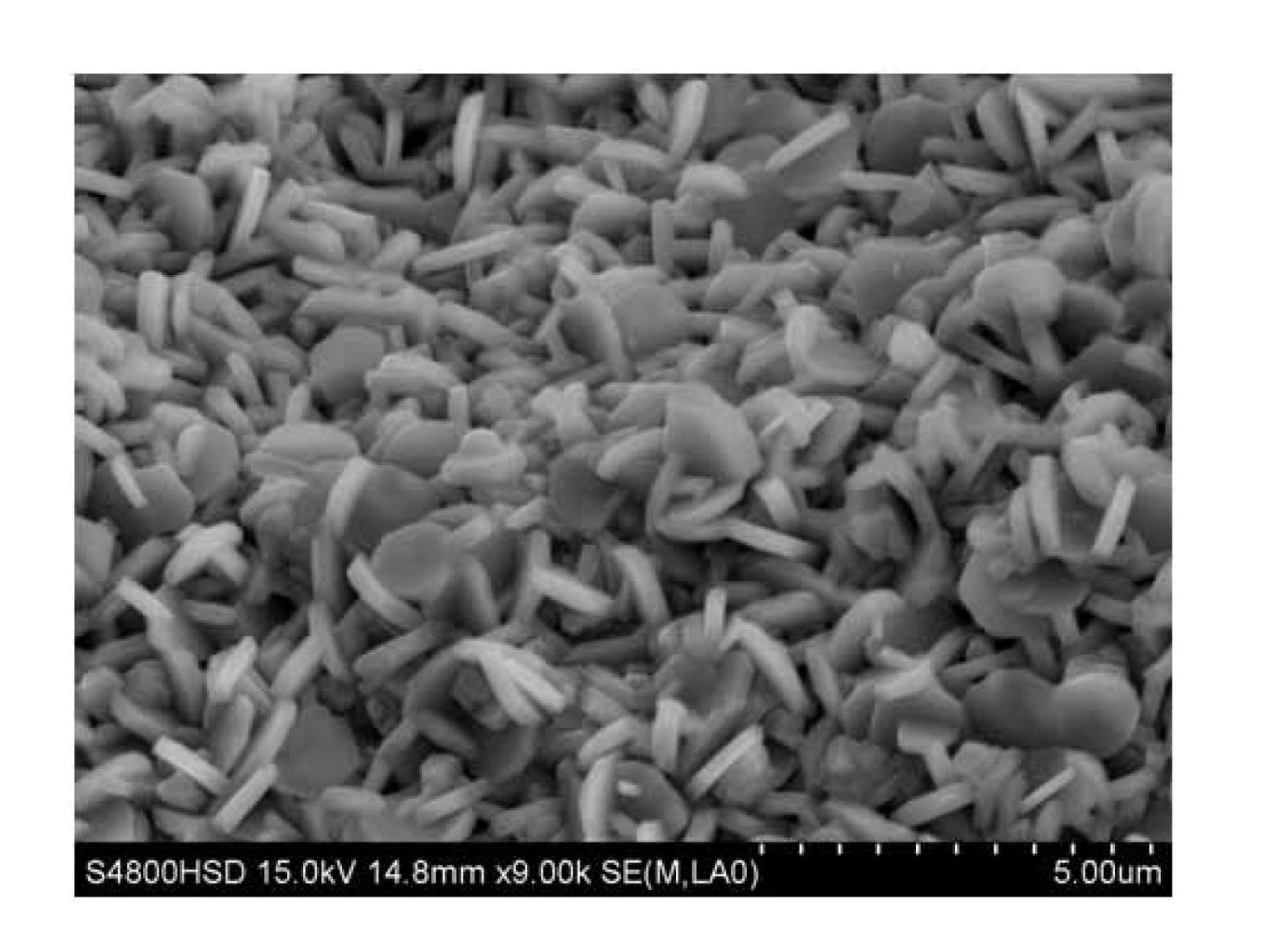

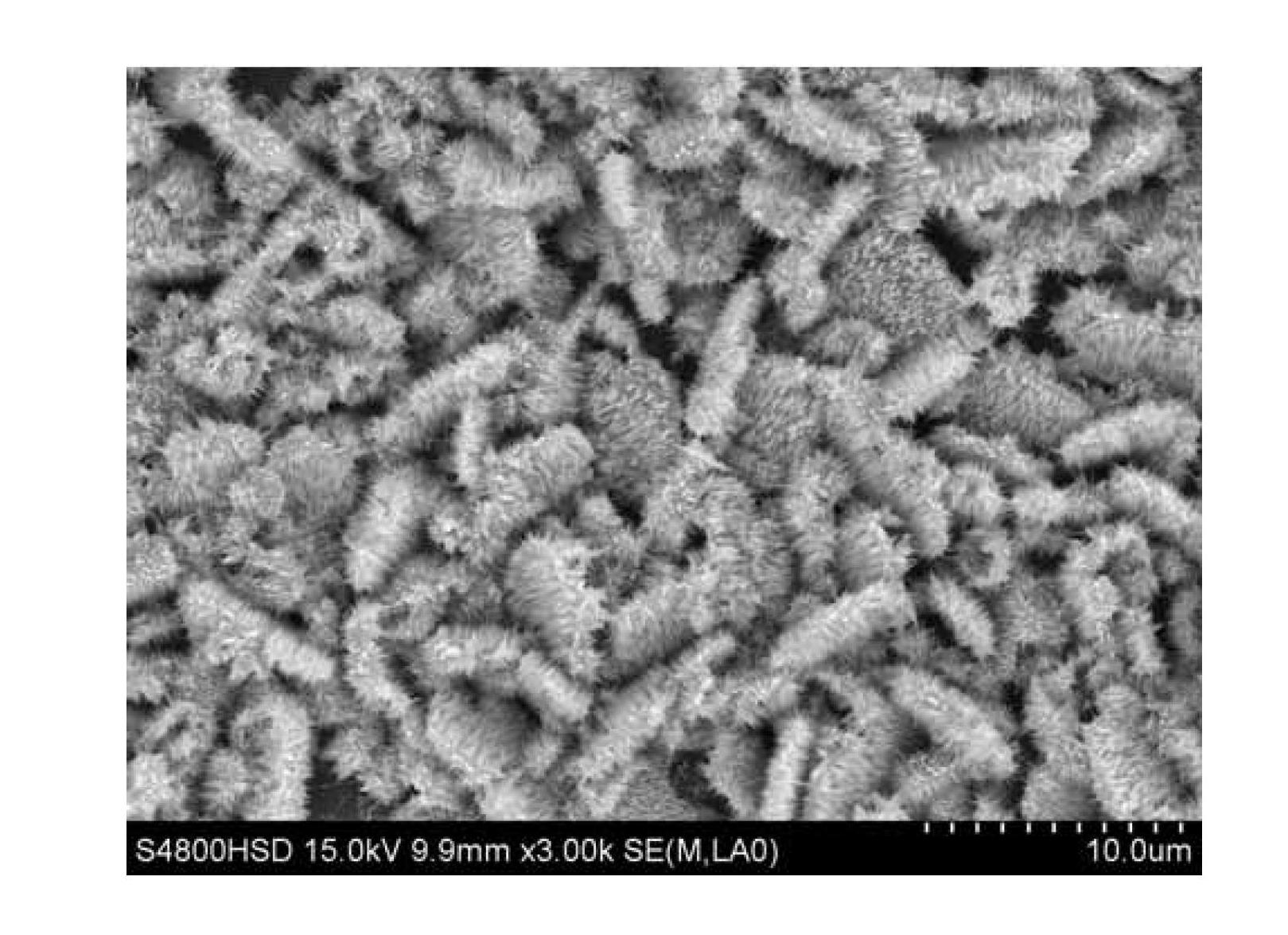

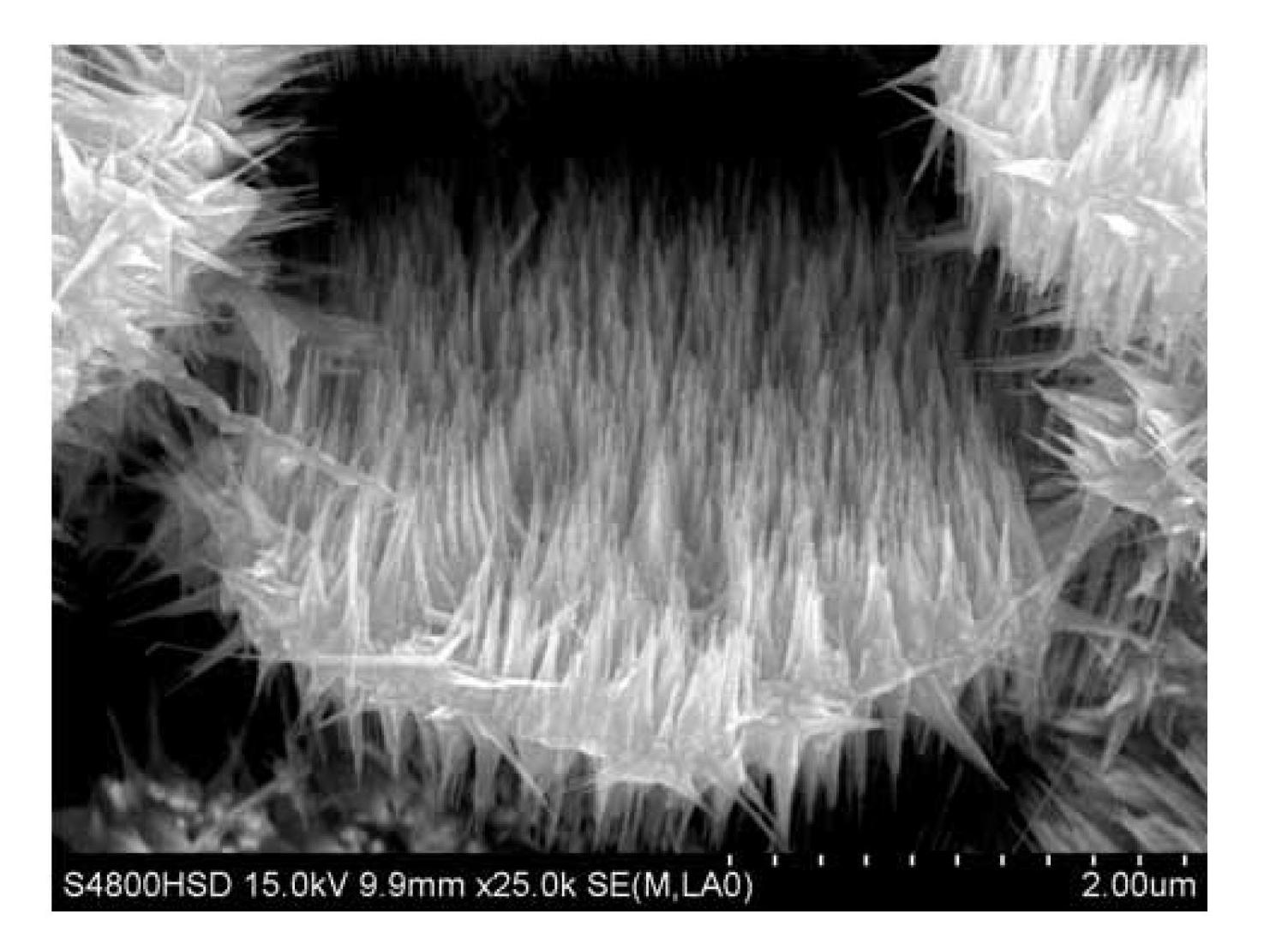

[0009] Specific embodiment one: the preparation method of the ZnO / ZnS heterostructure nanocone array of this embodiment is carried out according to the following steps: one, the single crystal silicon wafer is cleaned, and then the nano-gold film is sputtered on the single crystal silicon wafer as Silicon substrate; 2. Mix zinc oxide powder and zinc sulfide powder in a mass ratio of 1 to 25:1 as the source material, germanium powder as the catalyst, and place the source material, catalyst and silicon substrate in a high-temperature resistant container , where the source material is placed at one end of the high-temperature resistant container, and this end is placed at the center of the high-temperature reaction furnace, the catalyst is placed downstream of the source material, and the distance between the source material and the source material is 0.06-0.08m, and the silicon substrate Place it downstream of the source material, and the distance between it and the source materi...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that: the single crystal silicon wafer in step 1 is n-type or p-type. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the process of cleaning the monocrystalline silicon wafer in step one is: first use acetone to ultrasonically clean for 15 minutes, then use absolute ethanol to ultrasonically clean for 15 minutes, and finally Ultrasonic cleaning with deionized water for 15 min. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com