Synergistic heat radiation solar cell assembly and preparation method thereof

A technology of solar cell components and solar cells, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems affecting the aesthetics and practicability of cell components, low thermal conductivity of EVA packaging materials, space occupation and increased weight, etc. , to achieve the effect of improving photoelectric conversion efficiency and service life, improving heat conduction and heat dissipation performance, and small weight change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

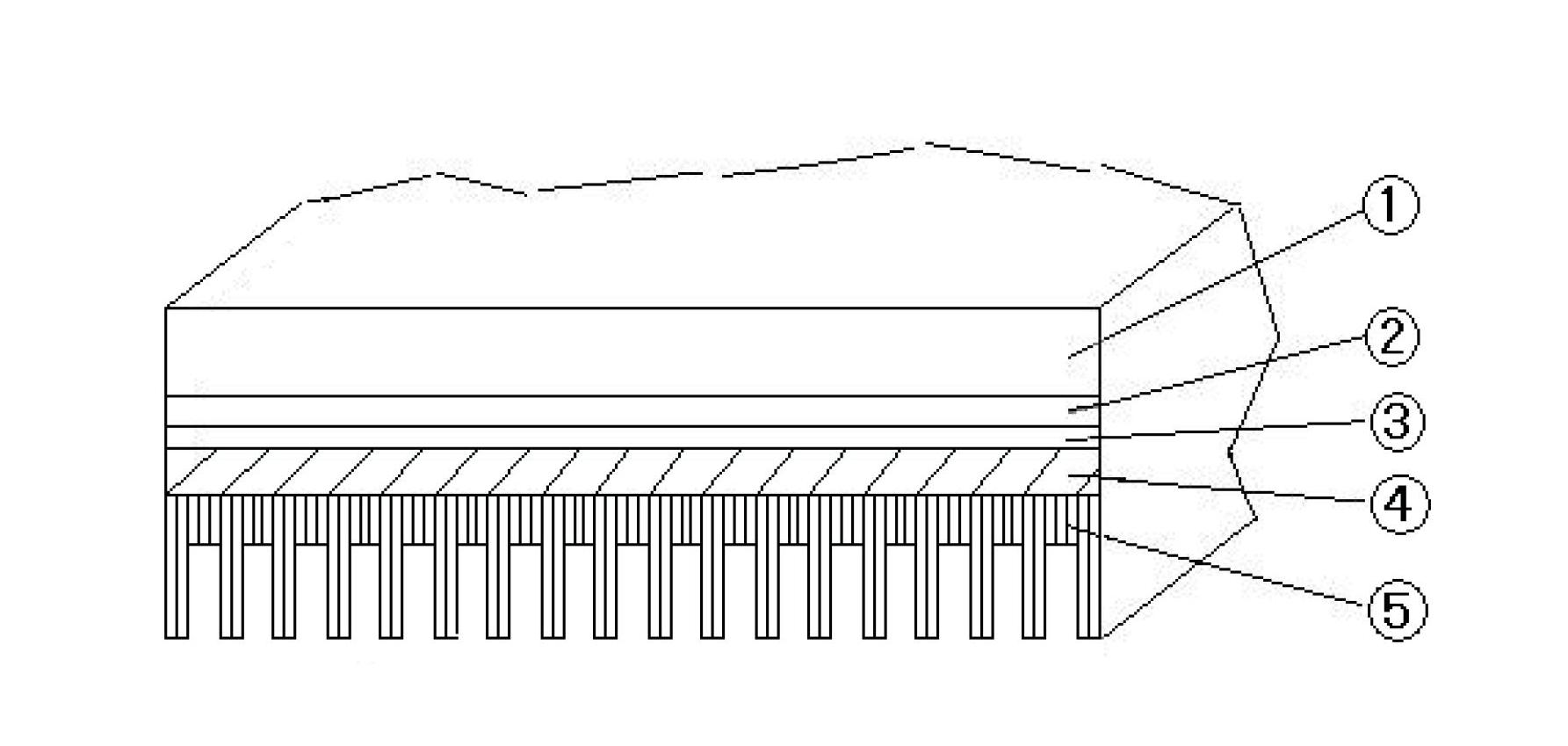

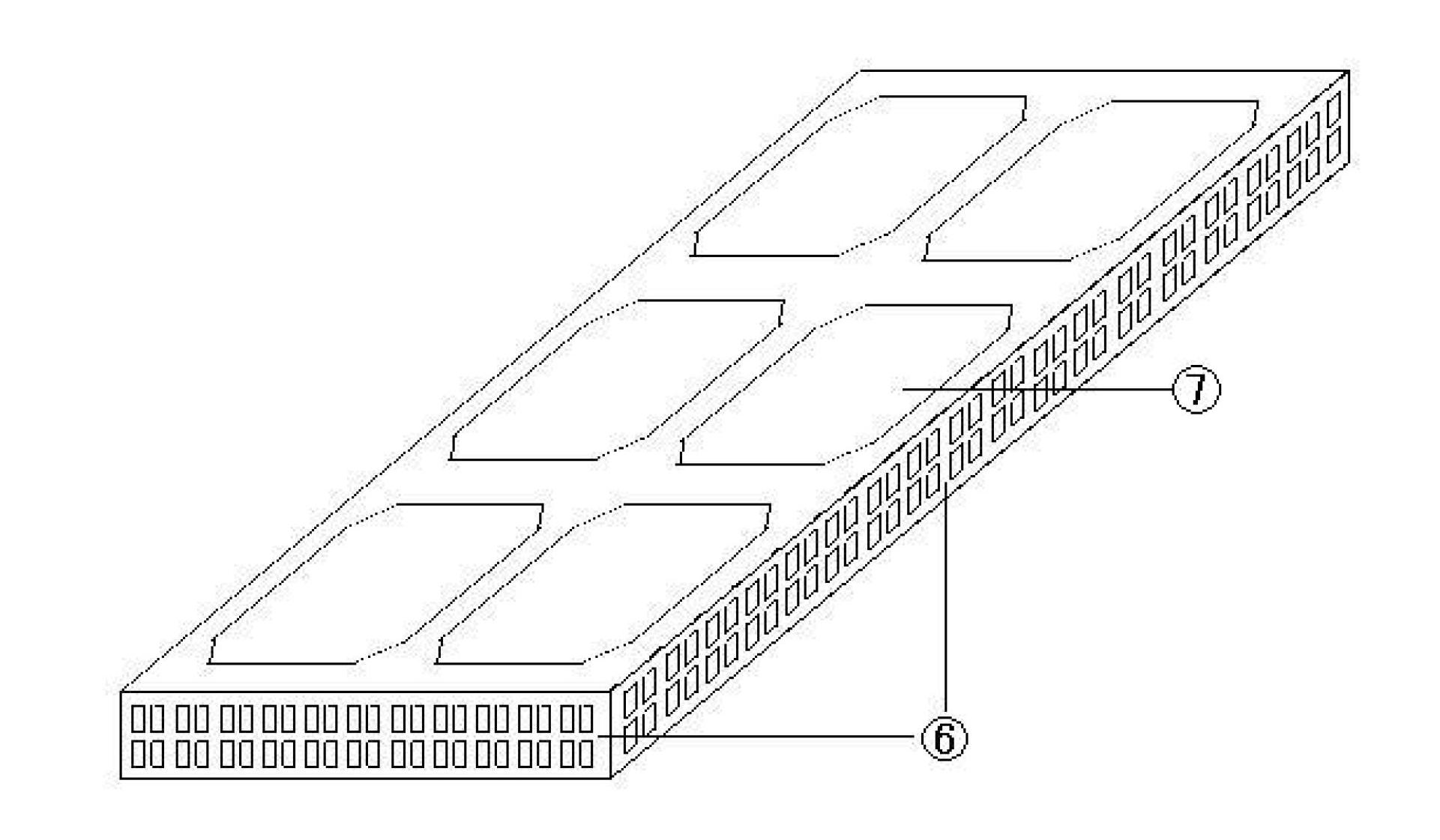

[0028] like figure 1 , figure 2 As shown, a solar cell module includes a module frame ⑥ and a module structure installed in the frame ⑥ with a reinforced heat dissipation backplane; the module structure includes: a light-transmitting front panel ① made of photovoltaic glass, a transparent EVA The sealing layer ②, the battery chip and circuit ③ encapsulated by the transparent EVA sealing layer ② and the thermally conductive composite EVA back-sealing adhesive film ④, and the heat dissipation backplane ⑤ with enhanced heat transfer comb teeth. The light-transmitting front plate (photovoltaic glass or plastic) ①, the transparent EVA layer ②, the solar cell chip and the circuit ③ all adopt the existing mature technology, and are applicable to the current solar cell structures of various combinations. The heat-conducting composite EVA back-sealing adhesive film ④ is obtained by extruding EVA resin, high-thermal-conduction insulating filler BN and other components through function...

Embodiment 2

[0033] refer to figure 1 , figure 2 As shown, a solar cell module includes a module frame ⑥ and a module structure installed in the frame ⑥ with a reinforced heat dissipation backplane; the module structure includes: a light-transmitting front panel ① made of photovoltaic glass, a transparent EVA The sealing layer ②, the battery chip and circuit ③ encapsulated by the transparent EVA sealing layer ② and the thermally conductive composite EVA back-sealing adhesive film ④, and the heat dissipation backplane ⑤ with enhanced heat transfer comb teeth. The light-transmitting front plate (photovoltaic glass or plastic) ①, the transparent EVA layer ②, the solar cell chip and the circuit ③ all adopt the existing mature technology, and are applicable to the current solar cell structures of various combinations. The heat-conducting composite EVA back-sealing adhesive film ④ is made of EVA resin and high heat-conducting insulating filler Si 3 N 4 and other components after functional c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com