Solar air source heat pump device used for vegetable and fruit drying

A technology of air source heat pump and solar energy device, which is applied in application, food processing, food science, etc., and can solve problems such as long drying time, high energy consumption, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

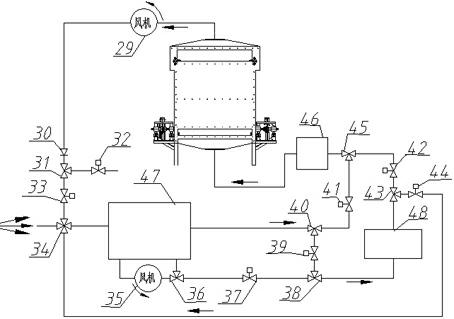

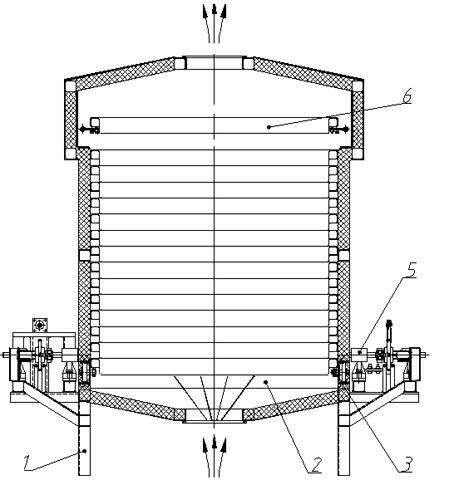

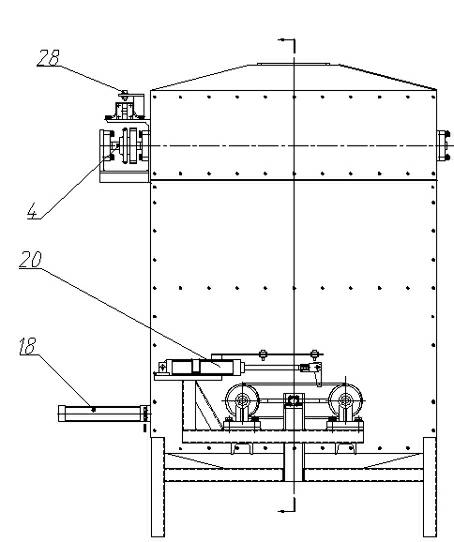

[0020] Example figure 1 As shown, a solar air source heat pump device for drying vegetables and fruits includes a drying box and a fan. The solar air source heat pump device includes an air source heat pump device 47 connected to each other through a three-way valve or a four-way valve, A solar device 48, an electric heating device 46 and a drying box, one end of the air inlet of the air source heat pump device 47 is connected to the A four-way valve 34, and the other end is connected to the B three-way valve 40, which is connected to the bottom of the air source heat pump device 47 The A fan 35 is connected to one end of the C three-way valve 36, and the other two ends of the C three-way valve 36 are respectively connected to the air source heat pump device 47 and one end of the A stop valve 37; one end of the solar device is connected to the D three-way valve 43 , the other end is connected with the other end of E three-way valve 38 and A stop valve 37 in turn; B three-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com