Ion beam certainty adding device applied in ion beam polishing process and ion beam polishing system

A technology of adding device and ion beam, applied in the field of ion beam deterministic adding device and ion beam polishing system, can solve the problem that it is difficult to achieve uniform convergence of full-frequency surface error and large gradient error removal processing, and it is difficult to realize large error gradient removal processing, It is difficult to remove the error low point and other problems to achieve the effect of improving surface roughness, simple structure and continuation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

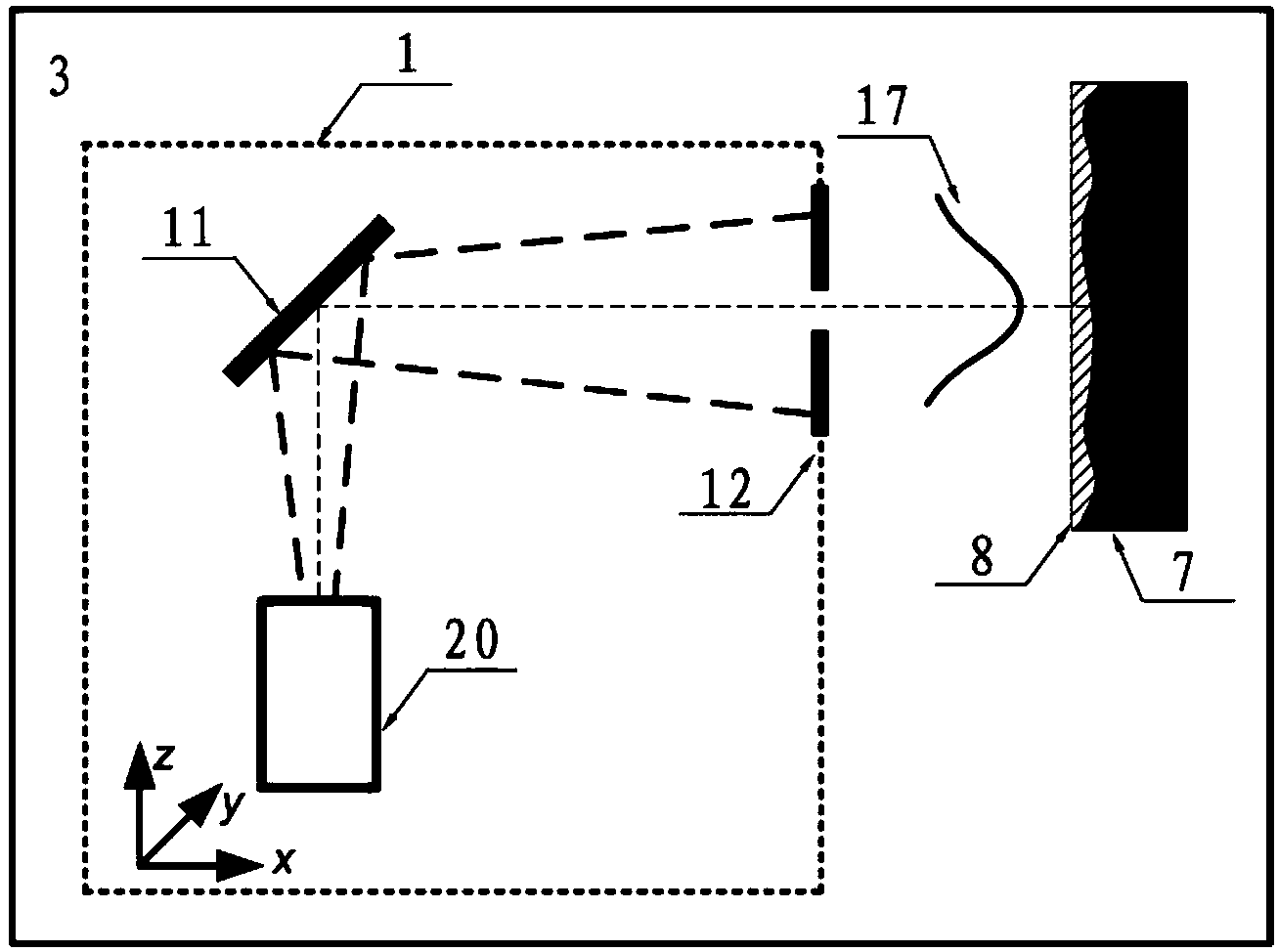

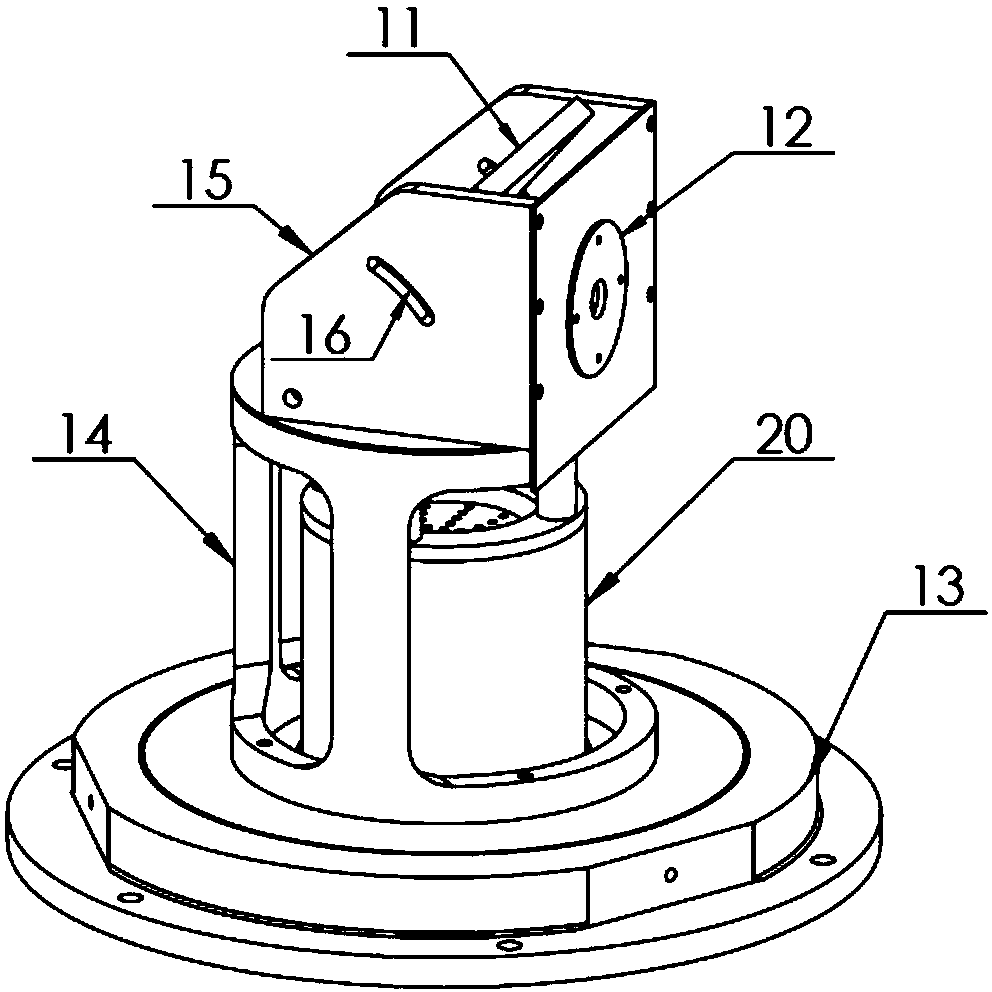

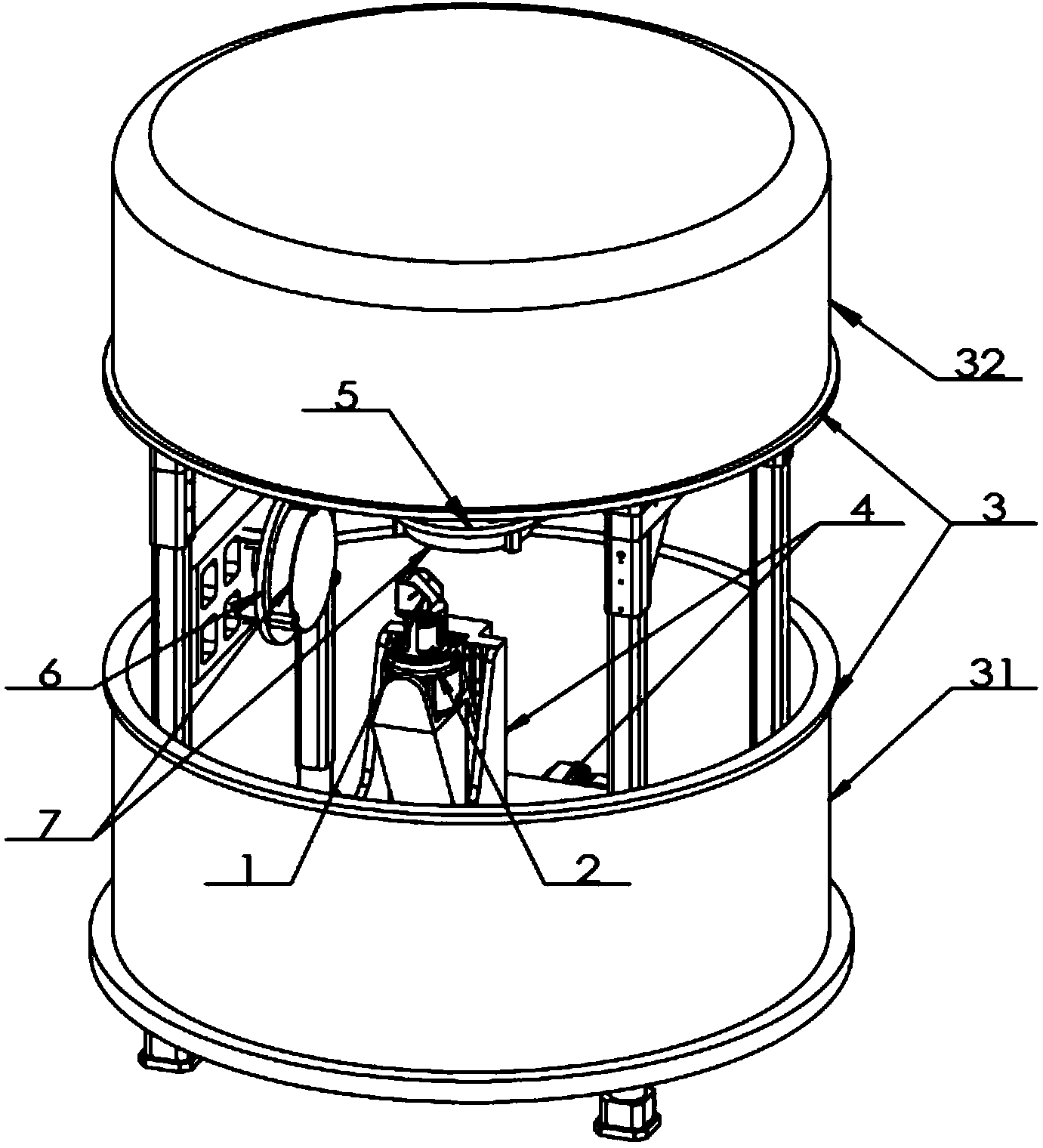

[0040] a kind of like figure 1 and figure 2 The shown ion beam deterministic adding device applied to the ion beam polishing process, the ion beam deterministic adding device 1 includes a support frame 14, an ion source 20 installed in the support frame 14 and an ion beam emitted by the ion source 20 The target material 11 to be bombarded, the support frame 14 includes a target material fixing fixture 15 for fixing the target material 11, and a fan-shaped waist-shaped hole 16 is provided on the target material fixing fixture 15, and the target material is installed in the waist-shaped hole 16 through a joint. The inclination angle of the target 11 can be adjusted through the waist hole 16 (that is, the incident angle of the ion beam can be changed). In this embodiment, the incident angle of the ion beam is 45°, and the type of the target 11 can also be changed as required. The support frame 14 is provided with an aperture 12 for intercepting the sputtering atomic flux of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com