Sequencing batch A2O sewage treatment method and device

A sewage treatment method and sequencing batch technology, applied in the field of sewage treatment, can solve the problems of restricting large-scale application, high idle rate of equipment, increased cost, etc., achieve a good biochemical environment for denitrification and phosphorus removal, reduce floor space and save energy. land use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

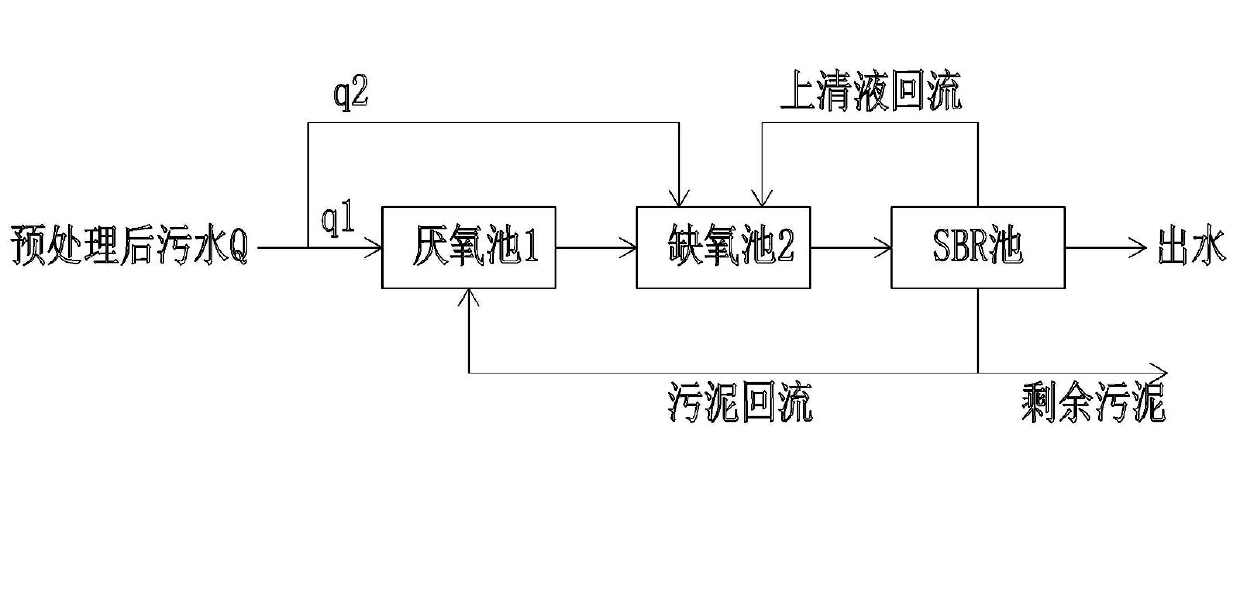

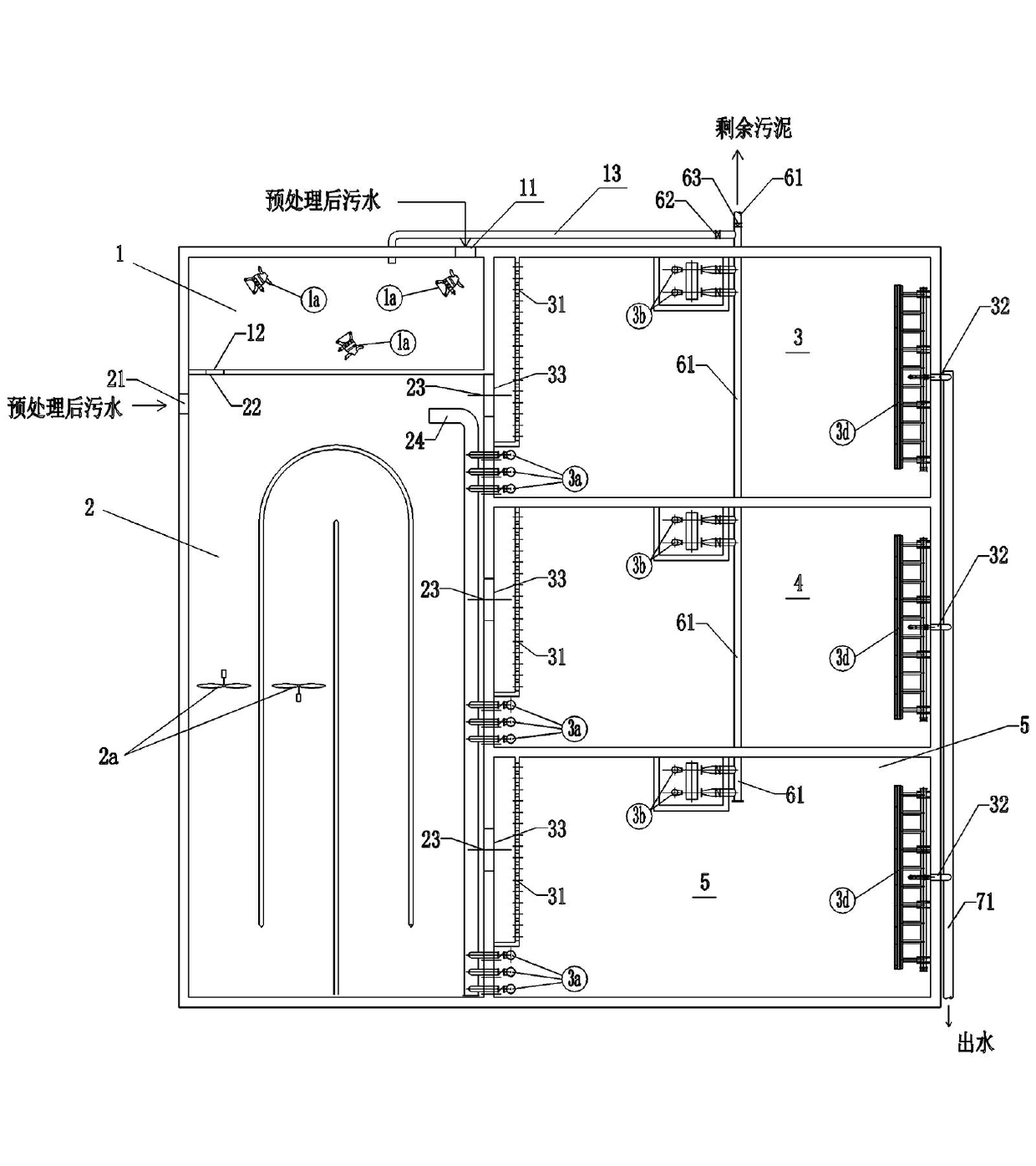

[0023] like image 3 As shown, the sequence batch type A2O sewage treatment method provided by the present invention adopts an anaerobic pool 1, an anoxic pool 2 and an SBR pool connected in sequence, and the SBR pool is provided with three: the first SBR pool 3, the SBR No. Second pool of 4 and SBR third pool of 5.

[0024] Anaerobic tank 1 is provided with water inlet 11, water outlet 12, agitator 1a; Anoxic tank 2 is provided with first water inlet 21, second water inlet 22, water outlet 23, pusher 2a, The water inlet hole 22 communicates with the water outlet hole 12 of the anaerobic tank;

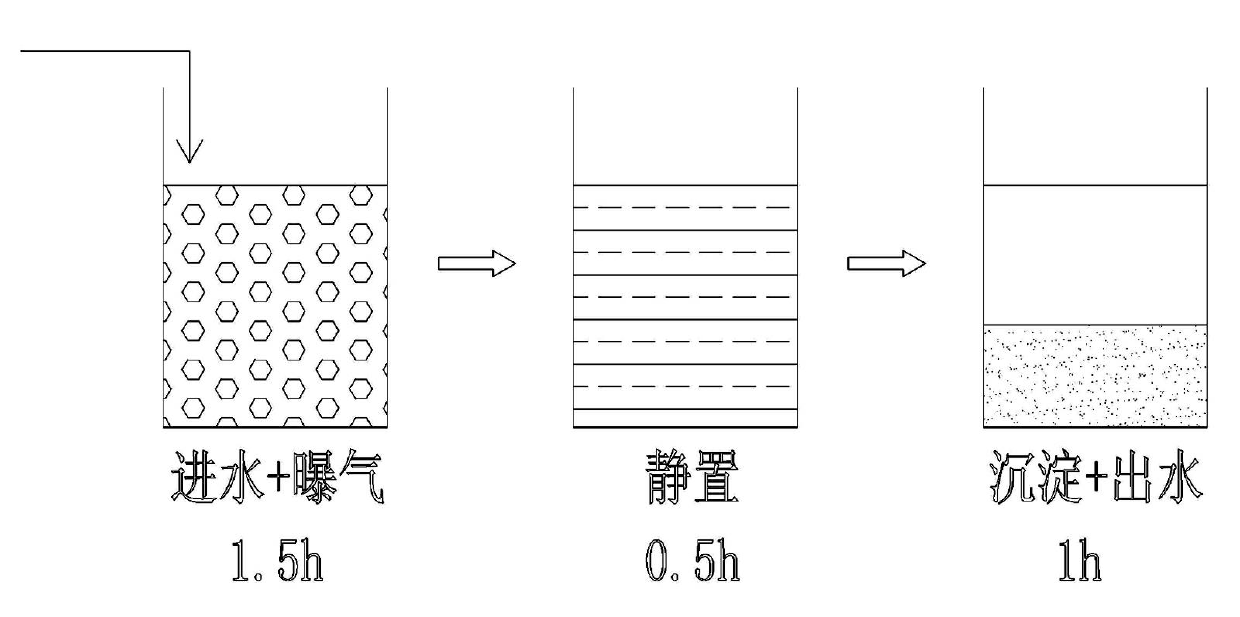

[0025] Each SBR pool has a water inlet 33 respectively, and the water inlet 33 is connected with the water outlet 23 of the anoxic pool 2, and a mixed liquid return pump 3a, a sludge discharge pump 3b, and a sludge discharge pipe 24 are respectively arranged in the pool , aeration device (not shown in the figure), decanting device 3d;

[0026] The mixed solution return pipe 24 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com