Novel environment-friendly efficient microorganism water quality purifying mixture and preparation method thereof

A high-efficiency microbial and water purification technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that the self-purification and adjustment ability of aquaculture water cannot meet the requirements of removing residual bait and fish and shrimp Problems such as excrement, ammonia nitrogen, nitrate, nitrite, sulfide exceeding the standard, antibiotics, aquaculture animal quality and export impact, etc., to improve survival rate and feed utilization rate, enhance digestion and absorption function, and reduce feeding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

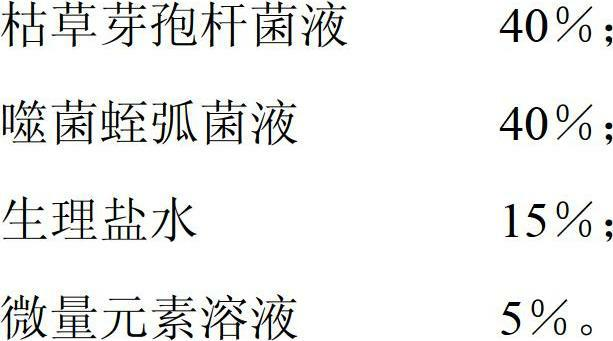

Embodiment 1

[0029] Preparation of novel environment-friendly and high-efficiency microbial water purification mixture of the present invention

[0030] A. Weigh 10g of yeast extract, 15g of molasses, 10g of peptone, 5g of sodium chloride, 0.5g of ferric sulfate, 1g of magnesium sulfate, 5ml of trace element solution, and 500ml of water.

[0031] Add the above raw materials into a 1000ml fermenter, adjust the pH value to 6.8-7.2, heat to 121°C for 30 minutes to sterilize, add Bacillus subtilis strains when cooled to 37°C, and cultivate at 36-38°C for 32 hours , to obtain the Bacillus subtilis liquid.

[0032] B. Weigh 10g of yeast extract, 15g of molasses, 10g of peptone, 5g of sodium chloride, 0.5g of ferric sulfate, 1g of magnesium sulfate, 5ml of trace element solution, and 500ml of water.

[0033] Add the above raw materials into a 1000ml fermenter, adjust the pH value to 6.8-7.2, heat to 121°C to sterilize for 30 minutes, add Enterobacter strains when cooled to 37°C, cultivate at 3...

Embodiment 2

[0038] Preparation of novel environment-friendly and high-efficiency microbial water purification mixture of the present invention

[0039] A. Weigh 10g of yeast extract, 15g of molasses, 10g of peptone, 5g of sodium chloride, 0.5g of ferric sulfate, 1g of magnesium sulfate, 5ml of trace element solution, and 500ml of water.

[0040] Add the above raw materials into a 1000ml fermenter, adjust the pH value to 6.8-7.2, heat to 121°C for 30 minutes to sterilize, add Bacillus subtilis strains when cooled to 37°C, and cultivate at 36-38°C for 32 hours, to obtain the Bacillus subtilis liquid.

[0041] B. Weigh 10g of yeast extract, 15g of molasses, 10g of peptone, 5g of sodium chloride, 0.5g of ferric sulfate, 1g of magnesium sulfate, 5ml of trace element solution, and 500ml of water.

[0042] Add the above raw materials into a 1000ml fermenter, adjust the pH value to 6.8-7.2, heat to 121°C for 30 minutes to sterilize, add Enterobacter strains when cooled to 37°C, cultivate at 36...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com