Method and device for making drinking water by coal mine water

A technology for drinking water and well water, applied in chemical instruments and methods, adsorption water/sewage treatment, light water/sewage treatment, etc., can solve the problems of no treatment measures, low fresh water recovery rate, etc., and reduce the water intake load , The effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method for producing drinking water from coal well water comprises the following steps in turn:

[0033] a. The raw water of coal well water flows through adding CaCl 2 The clarifier, the fluoride and sulfate in the raw water and the Ca in the clarifier 2+ A chemical reaction occurs and CaF is precipitated 2 and CaSO 4 ;

[0034] b. The effluent from the clarifier is pumped into the manganese sand filter together with the coagulant, and the Fe in the water 2+ and Mn 2+ Under the catalysis of manganese sand, Fe is precipitated 3+ and Mn 4+ ;

[0035] c. The effluent of the manganese sand filter is subjected to ultrafiltration treatment to remove bacteria and viruses;

[0036] d. The fresh water after ultrafiltration is then subjected to nanofiltration treatment to further remove Fe 2+ , Mn 2+ , Ca 2+ and Mg 2+ , and F - and Cl - .

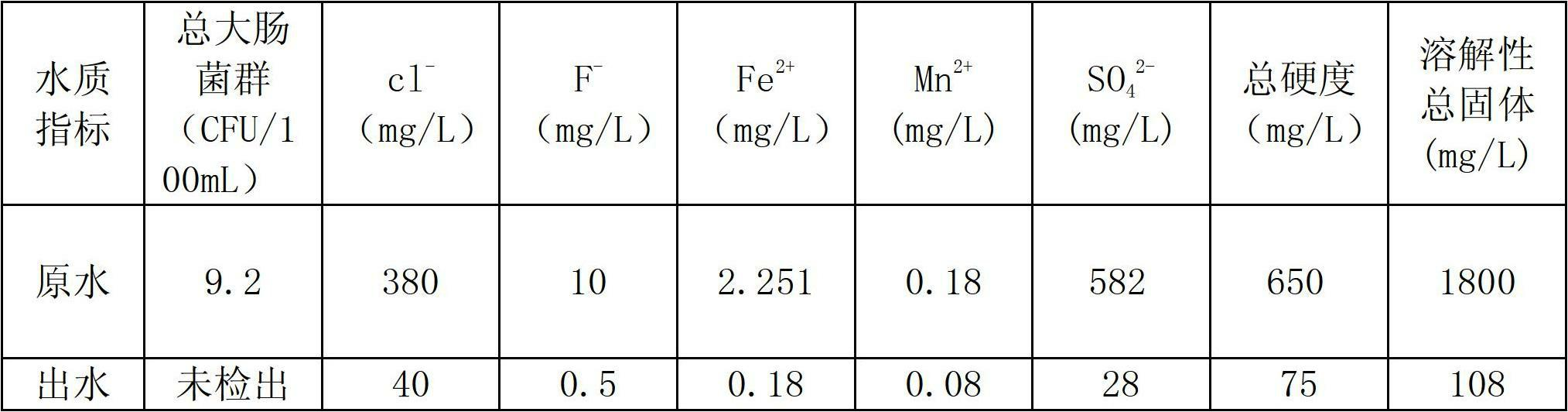

[0037] High salinity coal well water is treated by the above method, metal salts such as iron and manganese, fluoride, su...

Embodiment 2

[0042] The method for producing drinking water from coal well water comprises the following steps in turn:

[0043] a. The raw water of coal well water flows through adding CaCl 2 The clarifier, the fluoride and sulfate in the raw water and the Ca in the clarifier 2+ A chemical reaction occurs and CaF is precipitated 2 and CaSO 4

[0044] b. The effluent of the clarification tank flows through the inclined tube sedimentation tank, and the cinder and suspended matter are precipitated;

[0045] c. The effluent from the inclined tube sedimentation tank is collected into the raw water tank for re-sedimentation;

[0046] d. The effluent of the raw water tank is pumped into the manganese sand filter together with the coagulant, and the Fe in the water 2+ and Mn 2+ Under the catalysis of manganese sand, Fe is precipitated 3+ and Mn 4+ ;

[0047] e. The effluent of the manganese sand filter is subjected to ultrafiltration treatment to remove bacteria and viruses;

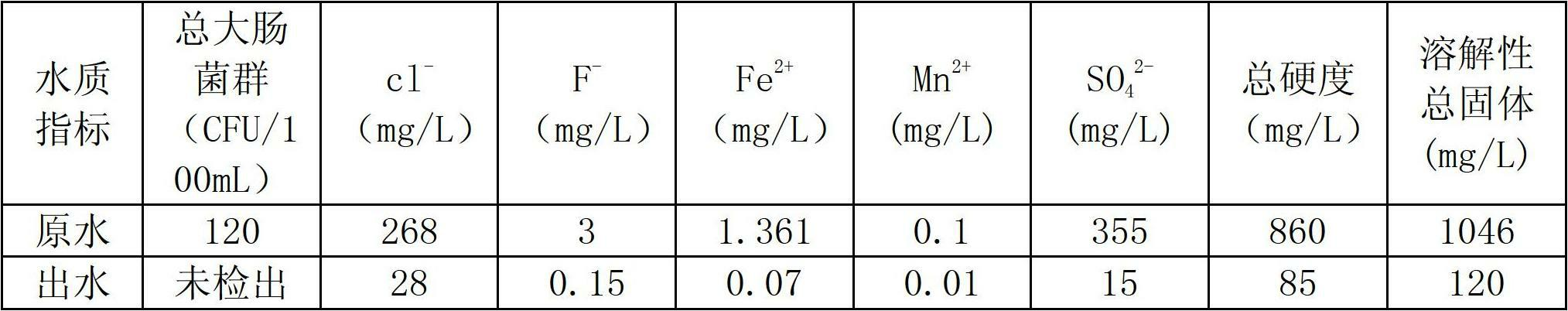

[0048] f....

Embodiment 3

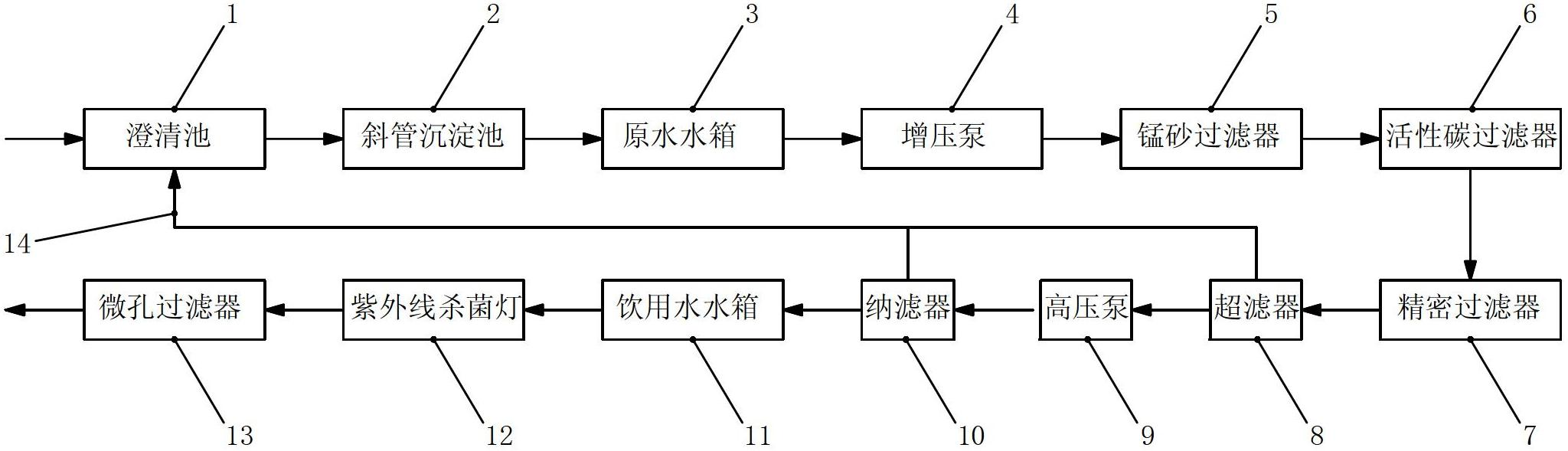

[0055] A device for producing drinking water from coal well water, including pipelines, which are arranged sequentially from the water inlet to the water outlet: clarifier 1, inclined tube sedimentation tank 2, raw water tank 3, booster pump 4, manganese sand filter Device 5, activated carbon filter 6, precision filter 7, ultrafilter 8, high pressure pump 9, nanofilter 10, drinking water tank 11, ultraviolet germicidal lamp 12 and microporous filter 13, described ultrafilter 8 and nanofilter Concentrated water outlets of the filter 10 are respectively provided with return pipelines 14 connected to the clarifier 1 . The filtration accuracy of the precision filter 7 is 5 μm; the filtration accuracy of the microporous filter 13 is 1 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com