Ultraviolet light ozone reaction process and device

A reaction device and ultraviolet light technology, which are applied in illumination water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of poor treatment effect, slow reaction speed, and low utilization rate of ozone, etc. Achieve the effect of fast reaction speed, small diameter and high ozone utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

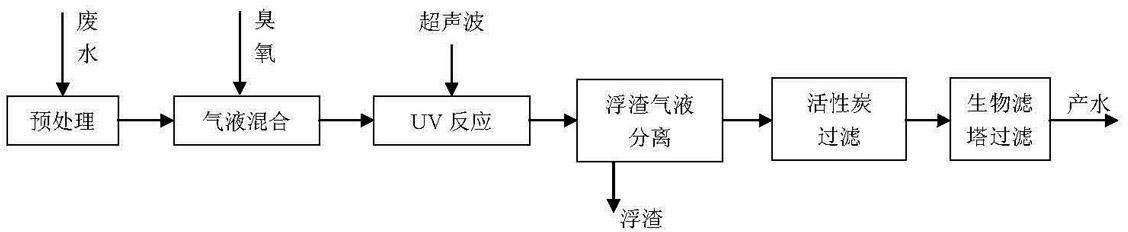

[0037] A kind of ultraviolet light ozone reaction technology, it comprises the following method steps:

[0038] (a) Pretreatment: Wastewater is pretreated to remove suspended solids, turbidity and chroma;

[0039] (b) Gas-liquid mixing: The wastewater treated in step (a) passes through the nano-bubble pump and fully mixes with the ozone and air in the nano-bubble pump to generate countless microbubbles with a diameter of 10 microns to 50 microns, and the ozone is compressed in the in microbubbles;

[0040] (c) UV reaction: the wastewater treated in step (b) is catalyzed by UV light, ozone produces hydroxyl radicals [ OH], and the hydroxyl radicals [ OH] break the molecular chains of pollutants in the wastewater, polluting substances are gradually degraded;

[0041] (d) Activated carbon filtration: the residual ozone and pollutants in the wastewater treated in step (c) are adsorbed by activated carbon;

[0042] (e) Biological filter tower filtration: the water treated i...

Embodiment 2

[0045] Such as figure 1 Shown, a kind of ultraviolet light ozone reaction technology, it is made up of following method steps:

[0046] (a) Pretreatment: Wastewater is pretreated to remove suspended solids, turbidity and chroma;

[0047] (b) Gas-liquid mixing: The wastewater treated in step (a) passes through the nano-bubble pump and fully mixes with the ozone and air in the nano-bubble pump to generate countless microbubbles with a diameter of 10 microns to 50 microns, and the ozone is compressed in the in microbubbles;

[0048] (c) UV reaction: the wastewater treated in step (b) is catalyzed by UV light, ozone produces hydroxyl radicals [·OH], and the hydroxyl radicals [·OH] break the molecular chains of pollutants in the wastewater, and at the same time Ultrasonic waves are input to pressurize the microbubbles, and the pollutants are gradually degraded;

[0049] (c1) Gas-liquid separation of scum: Micro-bubbles gather and float in the scum gas-liquid separation tow...

Embodiment 3

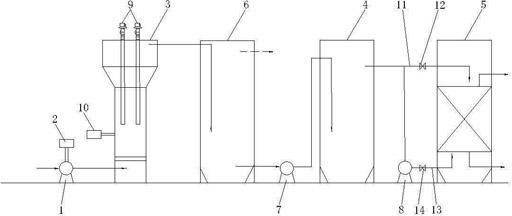

[0060] Such as figure 2 Shown, a kind of ultraviolet light ozone reaction device for realizing the ultraviolet light ozone reaction process of embodiment 1, it comprises nano-bubble pump 1, ozone generator 2, UV reaction tower 3, active carbon reaction tower 4, biofiltration tower 5 , the ozone generator 2 is connected with the nano-bubble pump 1, and the waste water passes through the nano-bubble pump 1, the UV reaction tower 3, the activated carbon reaction tower 4 and the biological filter tower 5 in sequence. The solid line arrows in the figure represent the flow direction of water, and the dotted line arrows in the figure represent the flow direction of scum.

[0061] Nanobubble pump 1 is a gas-liquid high-speed mixing pump, and ozone generator 2 delivers ozone O 3 To nanobubble pump 1. Ozone O 3 It is fully mixed with air and pretreated wastewater in the nano-bubble pump 1 to form countless nano-scale micro-bubbles with a diameter of 10 microns to 50 microns, and ozo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com