Prestressing tendon reinforced composite material and manufacturing method thereof

A technology for reinforcing composite materials and pre-existing stress tendons, which is applied in the field of preparing the pre-existing stress tendons reinforced composite materials, and can solve the problems affecting the safety, reliability, durability, easy cracking, and poor reliability of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

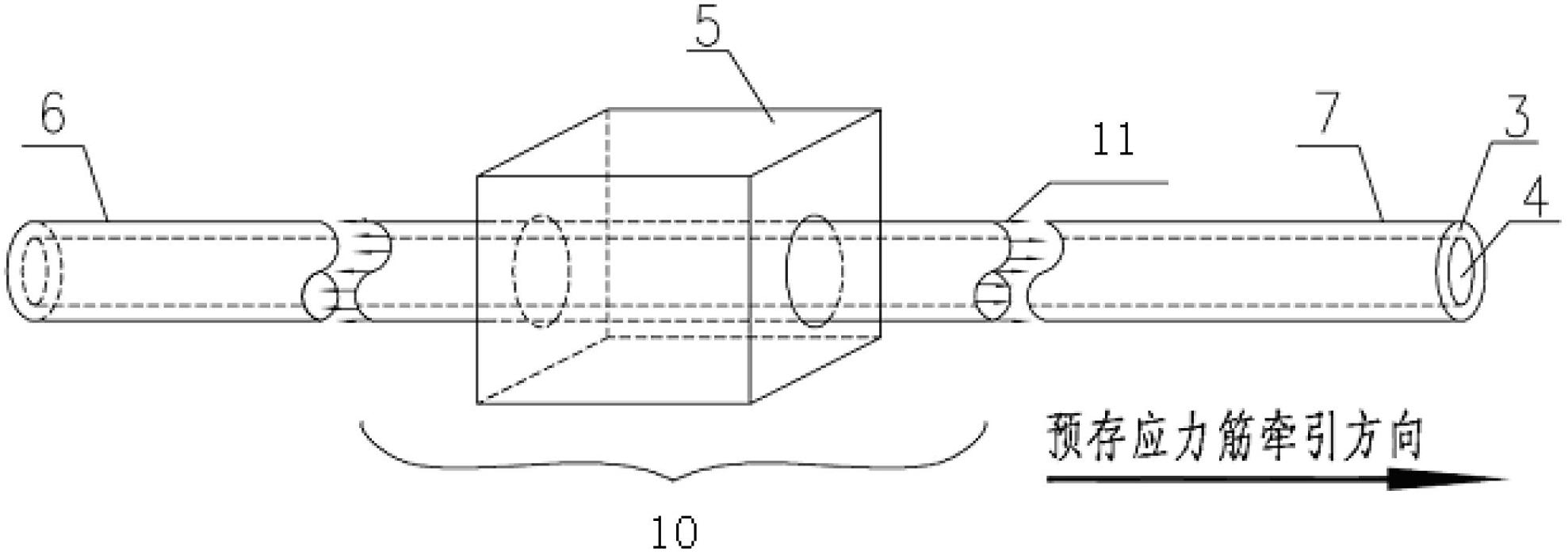

[0067] C / C outer tube 3, Si core pre-stored stress tendons 7 reinforced Si 3 N 4 The steps of the preparation method of the ceramic matrix composite material are as follows:

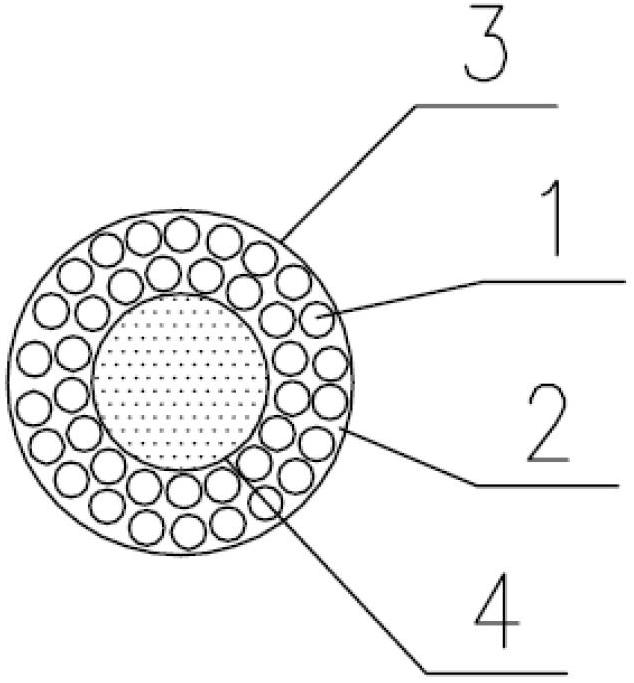

[0068] (1) Preparation of pre-existing stress tendon precursor 6: Si material is used as the core material in this example. Since elements such as C, N, or O have strong pinning dislocation capabilities in Si materials, a certain The amount of these elements can improve the shear strength, compressive strength and elastic modulus of the Si core body 4, but at the same time will increase the service temperature T of the Si core body 4. o .

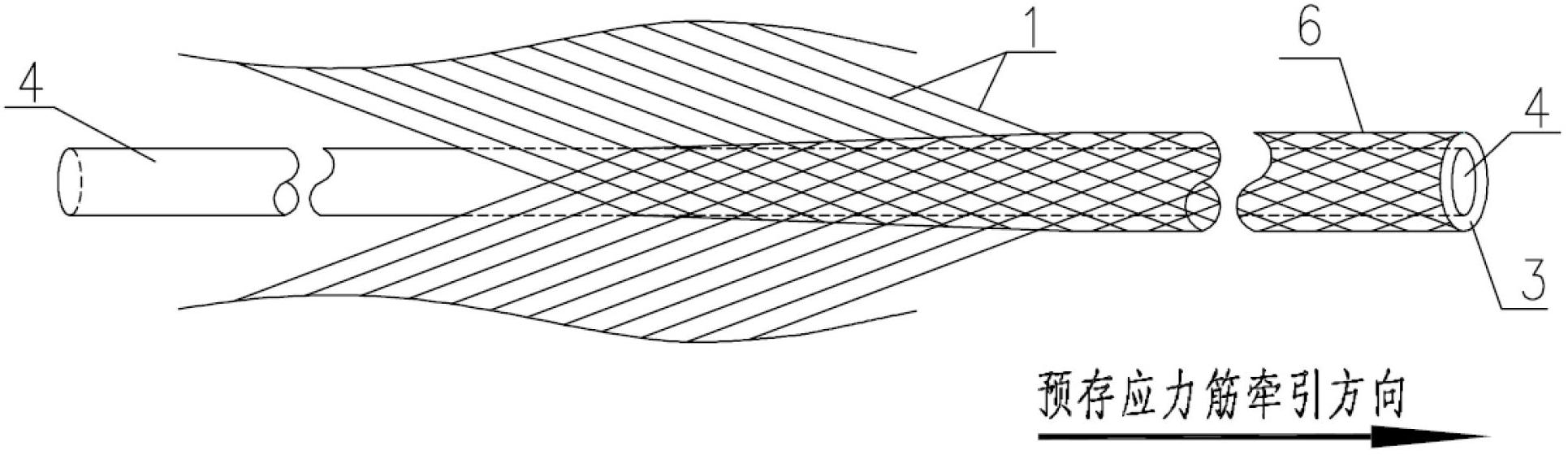

[0069] The core body 4 of this embodiment adopts the Si material doped with a small amount of N impurities, and the doped N impurity concentration is 10 15 ~10 20 / cm 3 Make it use temperature T o reaches 800°C, its T m The temperature was 1410°C. Such as figure 1 As shown, a plurality of T300 carbon fibers 1 that are woven or arranged in a single direction ...

Embodiment 2

[0079] C / C outer tube 3, Si core body pre-stored stress ribs 7 The preparation method of reinforced SiC ceramic matrix composite material is as follows:

[0080] (1) Preparation of pre-existing stress tendon precursor 6: Si material is used as the core material in this example. Since elements such as C, N, or O have strong pinning dislocation capabilities in Si materials, a certain The amount of these elements can improve the shear strength, compressive strength and elastic modulus of the Si core body 4, but at the same time will increase the service temperature T of the Si core body 4. o . For example, when C is added, as the content ratio of C in the core 4 increases, the shear strength, compressive strength and elastic modulus of the core increase accordingly. When the mole fraction of C is 50%, the core 4 material becomes a SiC ceramic material, and the T of SiC m It is around 2000°C, so by adjusting the content of C in Si, the T of the Si core m The temperature is modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com