Method for preparing dichloropropanol

A technology of dichloropropanol and hydrogen chloride, which is applied in the direction of introducing halogen preparation, hydroxyl compound preparation, chemical instruments and methods, etc., can solve the problems of reducing value, achieve the improvement of raw material utilization rate, specific catalytic performance, and increase reaction speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

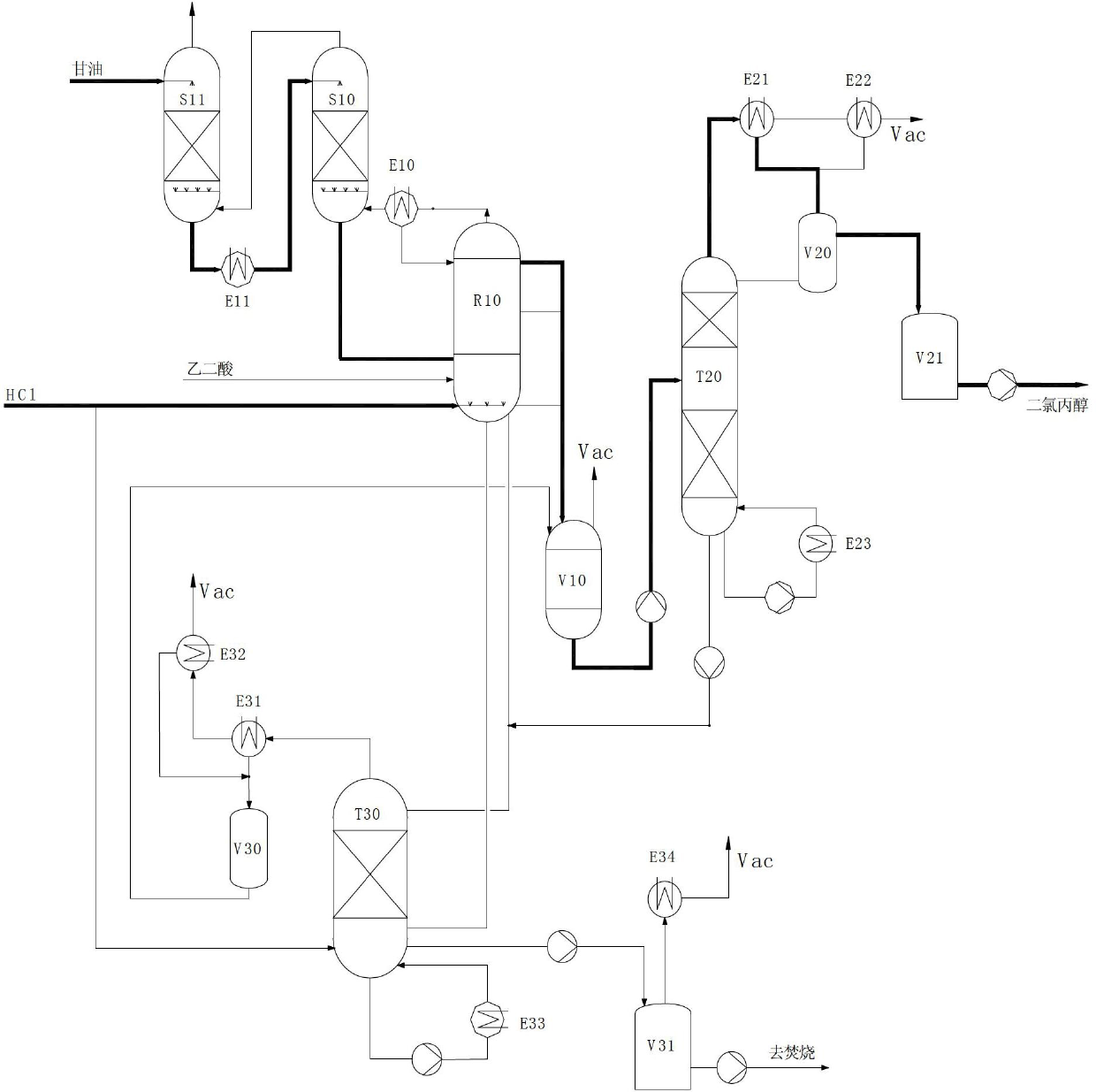

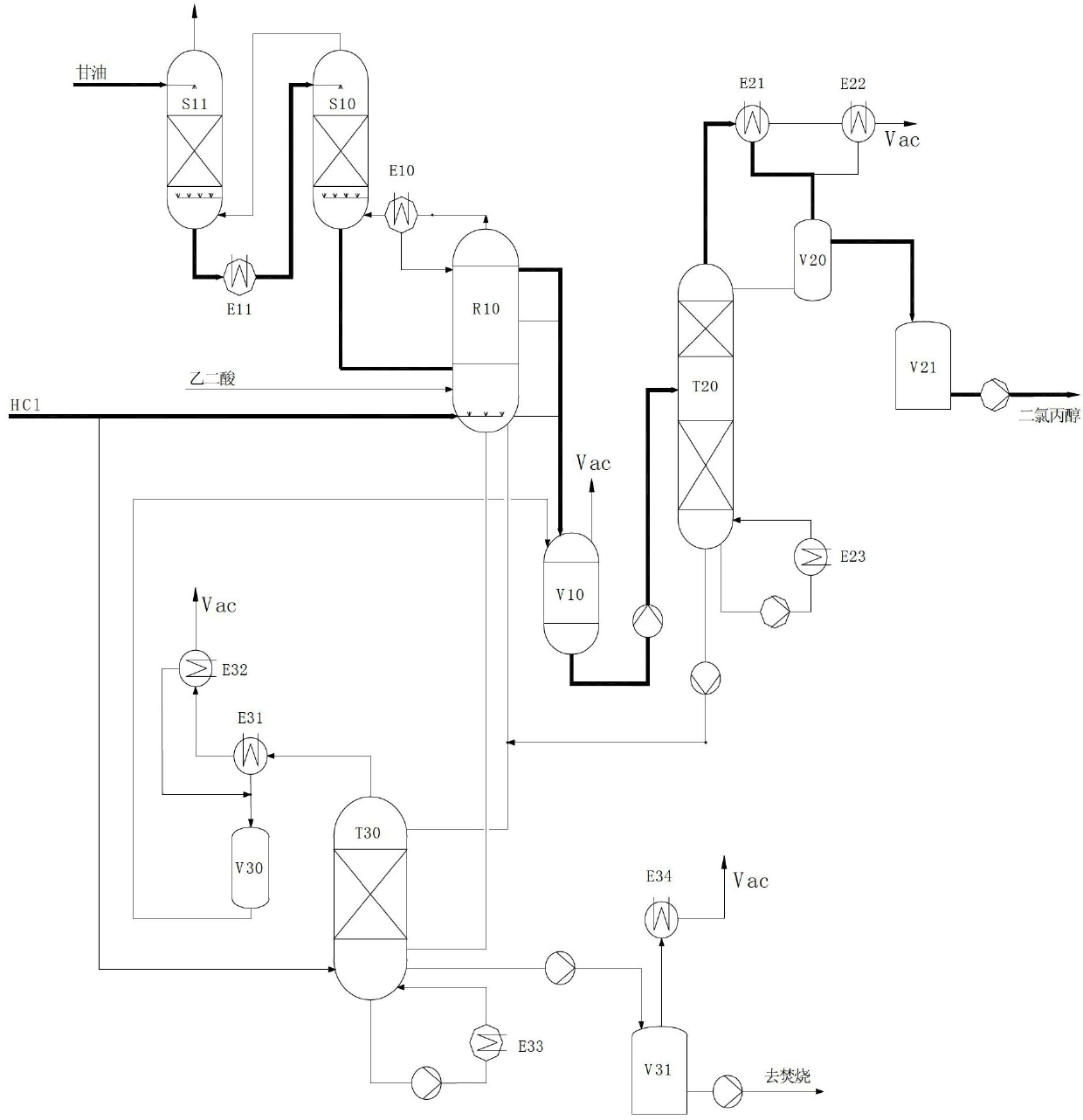

[0025] As shown in Figure 1, the glycerol with a weight purity of 95.0% (temperature at 50°C) and a flow of 4300kg / h flow through scrubber S20 and heat exchanger E11 to raise the temperature of glycerin to 130°C and enter scrubber S10, where the absorption part After the HCl enters the chlorination reactor (R10), under the action of the catalyst oxalic acid (weight concentration is about 2~3%), the chlorohydrin reaction is carried out with 4000kg / h HCl (pressure ≥0.2MPaG), that is, the above In the first and second steps of the reaction, the weight concentration of dichloropropanol produced is about 12%. The temperature of the chlorination reactor (R10) is maintained at 120~130℃, the pressure is 0.5bar, the diameter is 3.5m, the height is 10m, and the material is fiber reinforced material / perfluoroalkylate.

[0026] The mixture formed by the reaction overflows into the buffer tank V10, and then is sent to the vacuum distillation tower (T20, vacuum, temperature is 140℃, the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com