Method for producing epoxy chloropropane by dichloropropanol

A technology of epichlorohydrin and dichloropropanol, applied in the direction of organic chemistry, etc., to achieve the effect of reducing equipment size, saving energy, and low steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

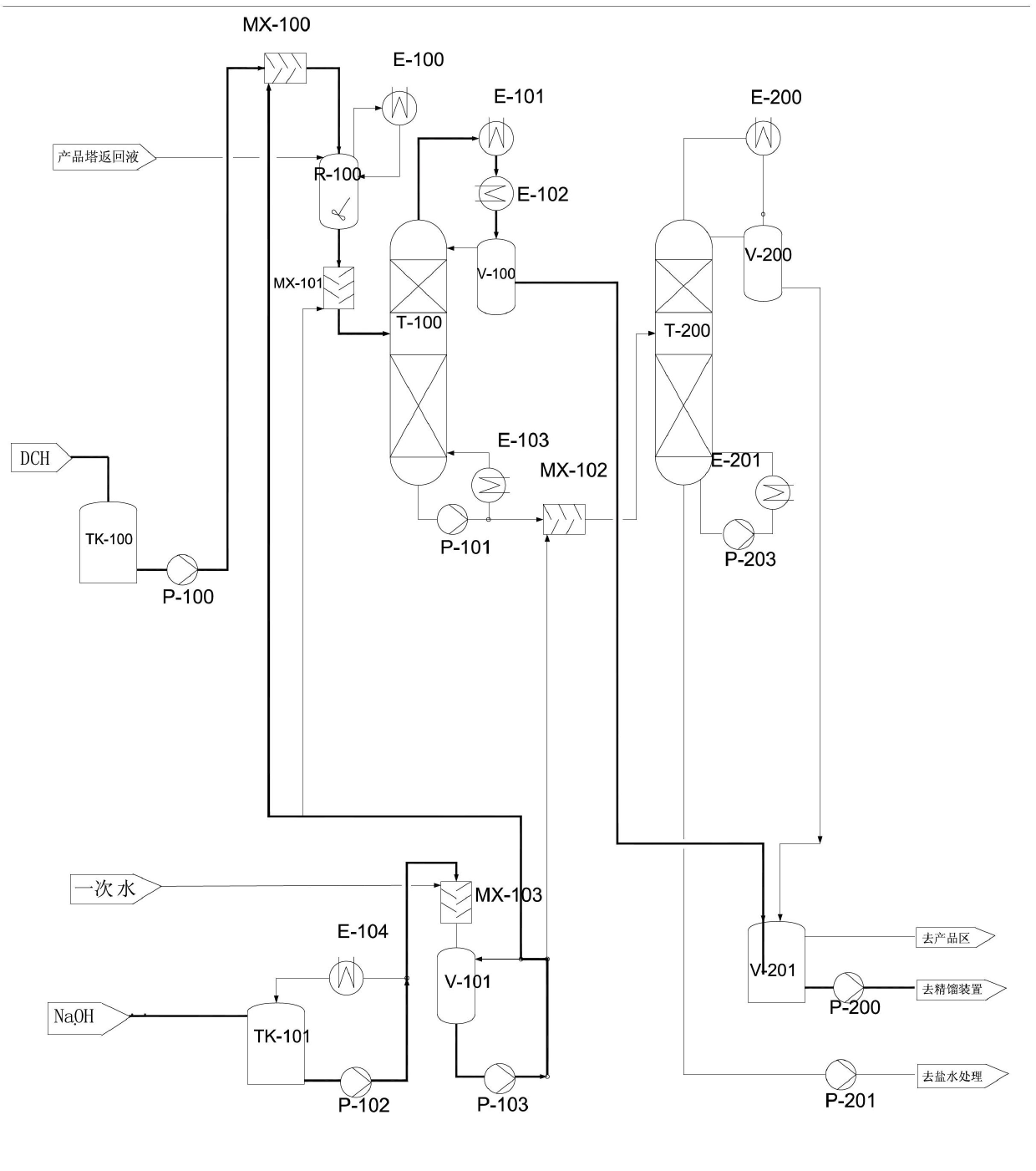

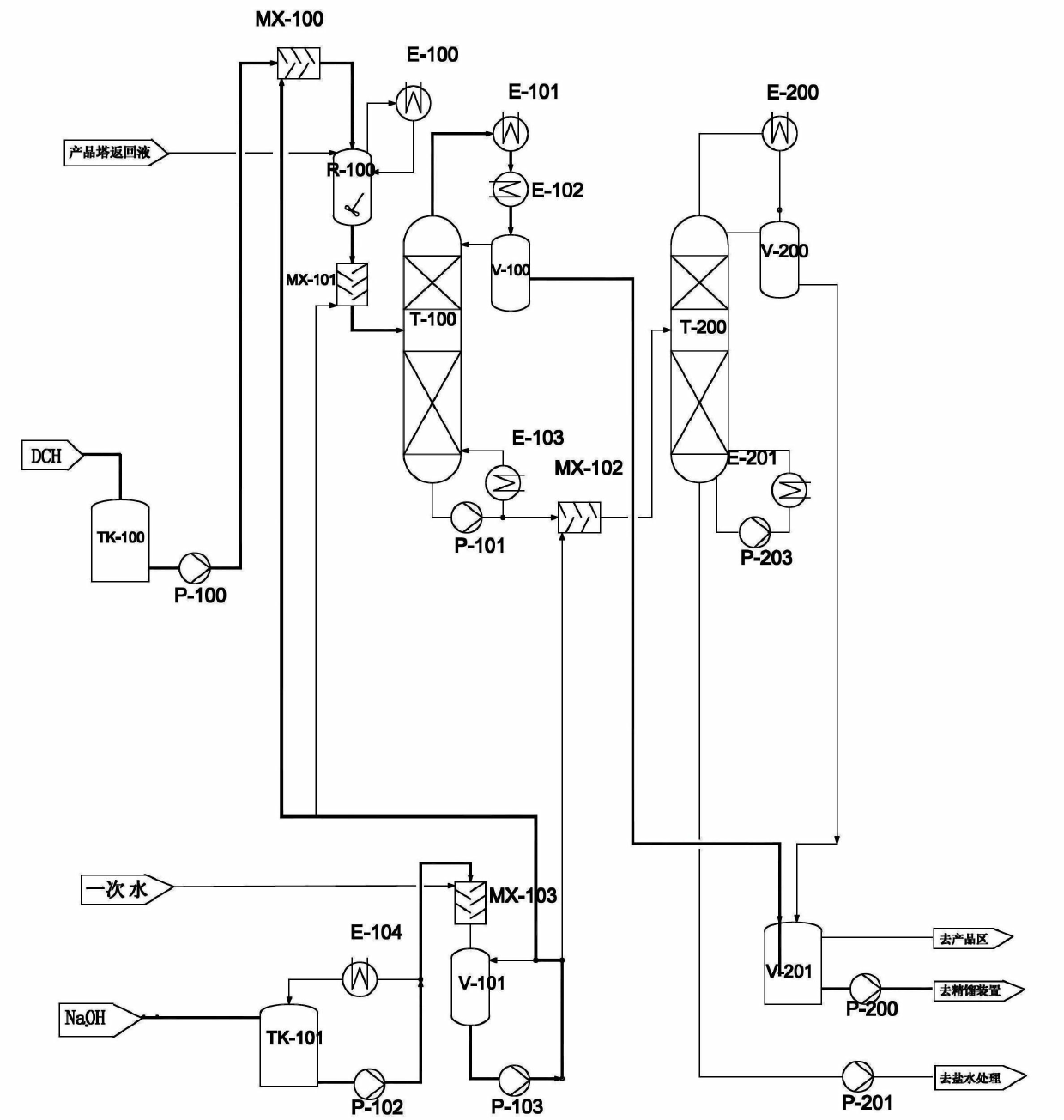

[0017] The dichloropropanol from chlorination is transported from the storage tank (TK-100) to the mixer (MX-100) through the pump (P-100), and at the same time, the sodium hydroxide preparation device in the device prepares about 20% of the After the sodium hydroxide solution is pressurized and preheated, it is finally sent to the mixer (MX-100) by the pump (P-103) to mix with dichloropropanol and then enters the reactor (R-100) for the first step of saponification reaction , the tempering water is produced by exchanging heat between the heat exchanger (E-100) and the waste water from the bottom of the saponification tower (T-100) and raising the temperature. After the first part of the reaction, it enters the mixer (MX-101) and then mixes with NaOH, then enters the stripping tower (T-100) for the second step of reaction, while performing distillation and separation, DCH (dichloropropanol) continues in the tower The reaction occurs, and the crude epichlorohydrin and water fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com