High-impact-resistance polystyrene polymer and preparation method thereof

A polystyrene, high-impact technology, applied in the field of material chemical industry, can solve problems such as poor heat resistance, and achieve the effects of improving thermal performance, heat resistance and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The specific implementation of the method for preparing the high-impact polystyrene polymer of the present invention will be described in detail below, but the implementation of the present invention is not limited to the following implementation.

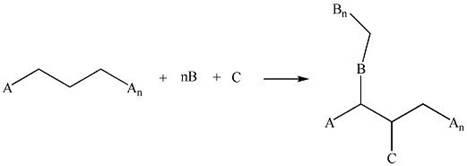

[0064] A kind of preparation method of high-impact polystyrene polymer, its step comprises:

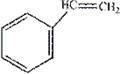

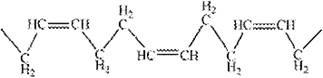

[0065] (1) Add 220.75ml (200g) of styrene monomer from which the polymerization inhibitor has been removed into a 500ml four-neck flask, cut 17.0g of high-cis polybutadiene rubber into granules and add it to styrene, and pass argon Protection, the stirring rate is set to 100rpm, and the sol time is 12 hours, so that the mixed high-cis polybutadiene rubber and styrene become a uniform mixture.

[0066](2) Add 1.21g of octavinyl-POSS monomer to the mixture in step (1), and at the same time, add 27.86ml (24.24g) of ethylbenzene (solvent) and continue stirring for 1 hour to obtain a homogeneous mixture.

[0067] (3) Add 0.0782ml (0.072...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com