Water-soluble degradable and efficiently antibacterial polymeric micelle and preparation method thereof

A biodegradable, polymer glue technology, applied in the directions of non-active ingredients medical preparations, pharmaceutical formulations, etc., can solve the problems of inability to apply in the biomedical field, poor antibacterial effect of polymers, poor antibacterial and bacteriostatic effect, etc. Achieve good bactericidal effect, improve bacteriostatic and bactericidal effects, and have a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Macromolecular initiator PEO 43 - b -PCL 20 -Synthesis of Br

[0036] 5g polyoxyethylene (PEO), 18g ε-caprolactone and toluene (50mL) were successively added to a 150mL flask, azeotropic removal of trace water, and the reaction was carried out at 120 o Under the condition of C for 24h, the product was precipitated in low-temperature n-hexane for 5 times, and dried in vacuum for 2 days to obtain white powdery PEO 43 - b -PCL 20 -OH. Subsequently, 10gPEO 43 - b -PCL 20 -OH and 1.9mL 2-bromoisobutyryl bromide were added to a 500mL flask, 250mL of solvent and 2mL of triethylamine were added, and the reaction was carried out for 24h. Filtration, extraction, washing, dissolution, precipitation, and finally vacuum drying to obtain the white powdery macromolecular initiator PEO 43 - b -PCL 20 -Br.

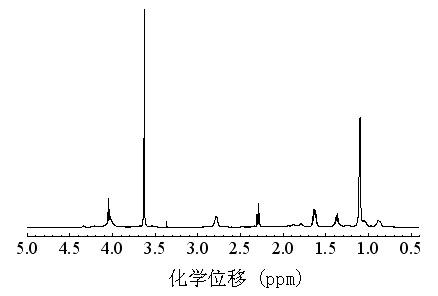

[0037](2) ATRP synthetic polymer

[0038] 1g macroinitiator PEO 43 - b -PCL 20 -Br, 0.033g catalyst cuprous bromide (CuBr), 0.039g ligand HMTETA, 0.8g monomer 2...

Embodiment 2

[0046] (1) Macromolecular initiator PEO 43 - b -PCL 20 -Synthesis of Br

[0047] 5g polyoxyethylene (PEO), 18g ε-caprolactone and toluene (50mL) were successively added to a 150mL flask, azeotropic removal of trace water, and the reaction was carried out at 120 o Under the condition of C for 24h, the product was precipitated in low-temperature n-hexane for 5 times, and dried in vacuum for 2 days to obtain white powdery PEO 43 - b -PCL 20 -OH. Subsequently, 10gPEO 43 - b -PCL 20 -OH and 1.9mL 2-bromoisobutyryl bromide were added to a 500mL flask, 250mL of solvent and 2mL of triethylamine were added, and the reaction was carried out for 24h. Filtration, extraction, washing, dissolution, precipitation, and finally vacuum drying to obtain the white powdery macromolecular initiator PEO 43 - b -PCL 20 -Br.

[0048] (2) ATRP synthetic polymer

[0049] 1g macroinitiator PEO 43 - b -PCL 20 -Br, 0.033g catalyst cuprous bromide (CuBr), 0.039g ligand HMTETA, 1.5g monomer ...

Embodiment 3

[0055] (1) Macromolecular initiator PEO 43 - b -PCL 30 -Synthesis of Br

[0056] 5g polyoxyethylene (PEO), 25g ε-caprolactone and toluene (60mL) were successively added to a 150mL flask, azeotropic removal of trace water, and the reaction was carried out at 120 o Under the condition of C for 36h, the product was precipitated in low-temperature n-hexane for 5 times, and dried in vacuum for 2 days to obtain white powdery PEO 43 - b -PCL 30 -OH. Subsequently, 10gPEO 43 - b -PCL 20 -OH and 1.5mL 2-bromoisobutyryl bromide were added to a 500mL flask, 250mL of solvent and 2mL of triethylamine were added, and the reaction was carried out for 24h. Filtration, extraction, washing, dissolution, precipitation, and finally vacuum drying to obtain the white powdery macromolecular initiator PEO 43 - b -PCL 30 -Br.

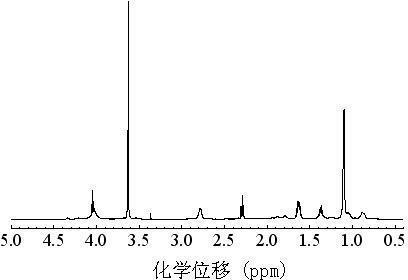

[0057] (2) ATRP synthetic polymer

[0058] 1g macroinitiator PEO 43 - b -PCL 30 -Br, 0.04g catalyst cuprous bromide (CuBr), 0.049g ligand PMDETA, 1.2g monomer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com