Thermal response poly-(carbonate-ether) capable of being biologically degraded and preparation method thereof

A biodegradable and carbonated technology, applied in the field of poly(carbonate-ether), can solve the problems of limited application and non-biodegradable polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

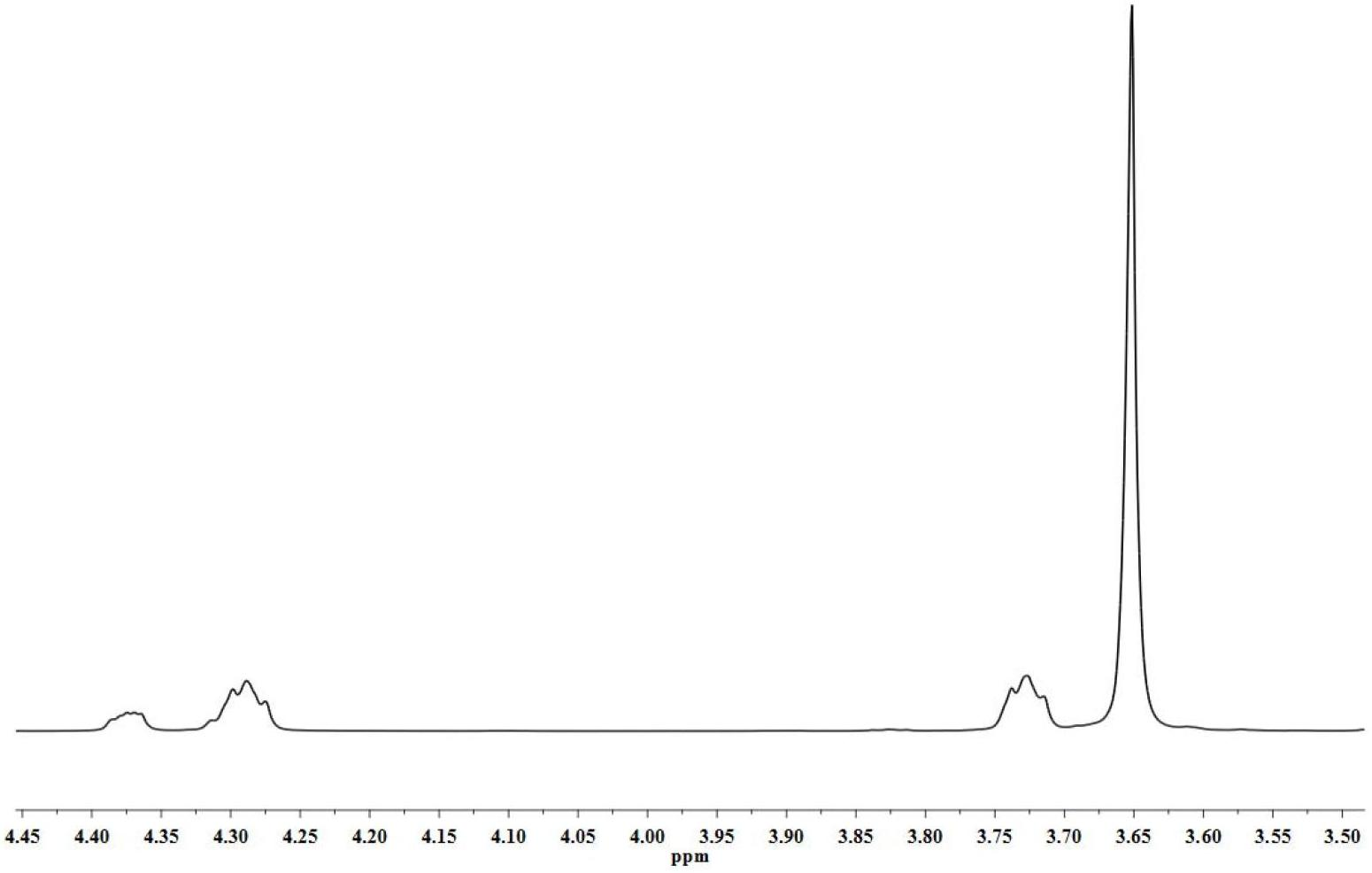

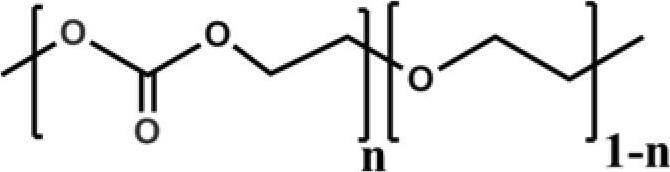

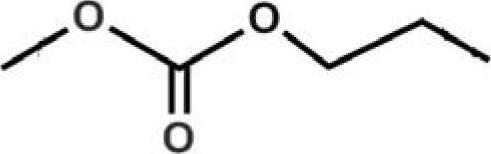

[0035] Correspondingly, the present invention also provides a preparation method of the above-mentioned poly(carbonate-ether), comprising the following steps: carrying out a copolymerization reaction of carbon dioxide and ethylene oxide under the catalysis of a double metal cyanide-rare earth complex composite catalyst , to give poly(carbonate-ether). The reaction formula is as follows:

[0036]

[0037] The poly(carbonate-ether) prepared above has a structural unit shown in formula I:

[0038]

[0039] Formula I,

[0040] Wherein, n is the ratio of the structural unit represented by formula II to the structural unit represented by formula I, and n is 4%-45%.

[0041]

[0042] Formula II.

[0043] The number average molecular weight of the poly(carbonate-ether) is 70~250kg / mol, preferably 70~247kg / mol; the transition temperature is 10~90°C, preferably 35~37°C.

[0044] According to the present invention, the double metal cyanide-rare earth complex composite cataly...

Embodiment 1

[0054] Preparation of Double Metal Cyanide-Rare Earth Complex Composite Catalyst

[0055] Double metal cyanide catalyst is prepared with reference to the method of Eur.Polym.J., 47(11), 2152, 2011:

[0056] 11.42g (0.084mol) ZnCl 2 Dissolve in a mixed solution formed by 60mL deionized water and 30mL tert-butanol (TBA), heat the formed solution to 50°C and keep the temperature for 20min, then add dropwise to the solution with a dropping funnel under stirring (300rpm) 1.32g (0.004mol) analytically pure K 3 [Co(CN) 6 ] and 20mL of deionized water, the dropwise addition takes 45min, keeping the reaction constant at 50°C, and continuing to stir at 50°C for 1h after the dropwise addition; the obtained suspension is centrifuged with a centrifuge (5000rpm) for 10min, poured out and separated The supernatant and the sediment were successively washed with 60mL 50℃ TBA / H 2 The mixed solution of O was pulped and washed 5 times, and finally washed once with TBA pulp, and the mixed solu...

Embodiment 2

[0060] 5mg Zn 3 [Co(CN) 6 ] 2 0.92ZnCl 2 2.05t-BuOH 1.93H 2 O, the composite catalyst of 8mg trichloroacetate yttrium and 10mL 1,3-dioxane composition is in CO 2 Under protection, add in evacuation (20~40Pa) at 80°C, fill with CO 2 Treat for 2 hours (filled with CO 2 10 times), and cooled to 0°C in the autoclave, at the same time, 100mL of ethylene oxide was added into the autoclave, and the pressure of carbon dioxide in the autoclave reached 4.0MPa quickly through the carbon dioxide pressure regulator. The polymerization reaction temperature was 90° C., the reaction time was 6 hours, and the stirring speed was 500 rpm. After the polymerization, the autoclave was cooled to 0°C with a cold water bath, and the residual carbon dioxide in the autoclave was slowly removed, and dichloromethane was added into the autoclave until the polymer was diluted to facilitate passing through the G2 glass sand core funnel. Filter the diluent through a sand core funnel to remove the catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transition temperature | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com