Novel halogen-free flame-retardant master batch material

A flame retardant masterbatch, a novel technology, applied in the field of novel flame retardant masterbatch materials, can solve the problems of operator's physical harm, poor dispersion and compatibility, low flame retardant content, etc., to achieve environmental friendliness, no corrosion Good performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

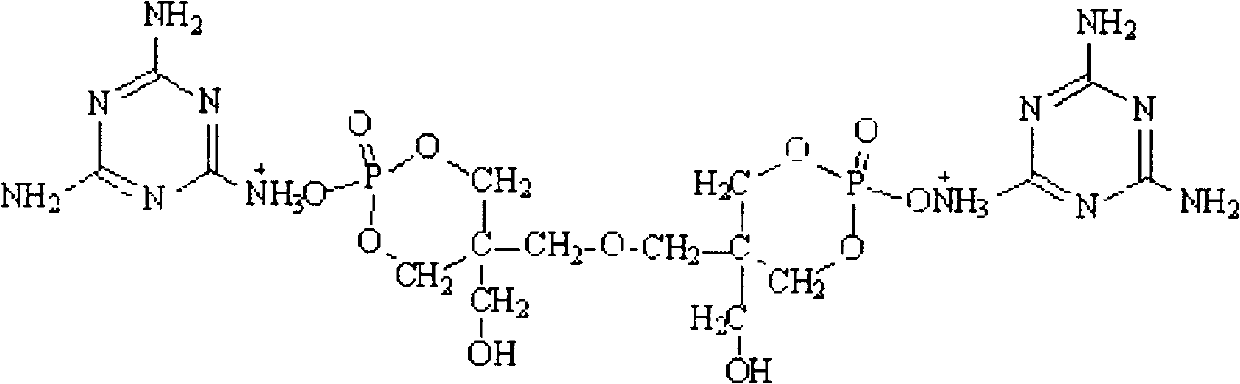

Image

Examples

Embodiment 1

[0021] Mix 33.3g of amine polyphosphate with a size of 5-7μm, 16.7g of dipentaerythritol, and 0.1g of composite lubricant, and then add a mixture of 20g of maleic anhydride-grafted polypropylene and 80g of polypropylene. The above mixture is fed into a twin-screw extruder, extruded and granulated. A flame retardant polypropylene masterbatch with a flame retardant content of 33.3% by weight was obtained.

[0022] Using a 25-ton vulcanizing machine, mold the above-mentioned flame-retardant masterbatch at 180°C, and make a sample with a universal prototype machine. The sample size is 100×10×3mm, and the oxygen index meter JF-3 is used, according to the ASTME-1354 standard. Determination of the flame retardant properties of the material; make a dumbbell-shaped sample with a size of 150×10×4mm and 80×10×4mm, use a SANS electronic universal testing machine, and measure the tensile and bending strength of the material according to ASTM D638 and ASTM D256 standards . The test result...

Embodiment 2

[0024] Mix 53.3g of amine polyphosphate with a size of 5-7μm, 26.7g of dipentaerythritol, and 0.16g of compound lubricant, and then add 24g of maleic anhydride-grafted polypropylene and 96g of polypropylene mixture. The above mixture is fed into a twin-screw extruder, extruded and granulated. A flame retardant polypropylene masterbatch with a flame retardant content of 40% by weight was obtained.

[0025] Using a 25-ton vulcanizer, add the above-mentioned 64g flame-retardant masterbatch and 12.8g polypropylene into a twin-roller plastic mixer, knead at 170°C for 10 minutes to make it evenly mixed, and use a 25-ton vulcanizer to mold it at 180°C. Universal sample making machine sample, the sample size is 100×10×3mm, using the oxygen index meter JF-3, according to the ASTME-1354 standard, to measure the flame retardancy of the material; the sample size is 150×10×4mm dumbbell-shaped and 80×10×4mm, using SANS electronic universal testing machine, according to ASTM D638 and ASTM D...

Embodiment 3

[0027] Mix 82.2g of amine polyphosphate with a size of 5-7μm, 41.1g of dipentaerythritol, and 0.25g of compound lubricant, and then add 7.8g of maleic anhydride-grafted polypropylene and 25g of polypropylene mixture. The above mixture is fed into a twin-screw extruder, extruded and granulated. A flame retardant polypropylene masterbatch with a flame retardant content of 75% by weight was obtained.

[0028] Using a 25-ton vulcanizer, add the above-mentioned 40g flame-retardant masterbatch and 40g polypropylene into a twin-roller plastic mixer, knead at 170°C for 10 minutes to make it evenly mixed, and use a 25-ton vulcanizer to mold it at 180°C. Sampling machine sample, the sample size is 100 × 10 × 3mm, using the oxygen index meter JF-3, according to the ASTME-1354 standard, to measure the flame retardancy of the material; the sample size is 150 × 10 × 4mm dumbbell shape and 80 ×10×4mm, using SANS electronic universal testing machine, according to ASTM D638 and ASTM D256 stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com