Additive composite used for preparing expandable polystyrene, and preparation method and application thereof

A technology of expandable polystyrene and composition, applied in the field of preparing expandable polystyrene particles, can solve problems such as environmental impact, and achieve the effect of easy transportation, high strength, good flame retardancy and good balance of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0053] Embodiment 1~7 prepares predispersion particle

[0054] Step 1, mix and disperse the raw materials evenly with a dry mixer according to the ratio in Table 1;

[0055] Step 2: Melting uniformly dispersed raw materials at 80 to 130° C. through a screw extruder, extruding, cooling, and cutting into pellets to prepare pre-dispersed particles.

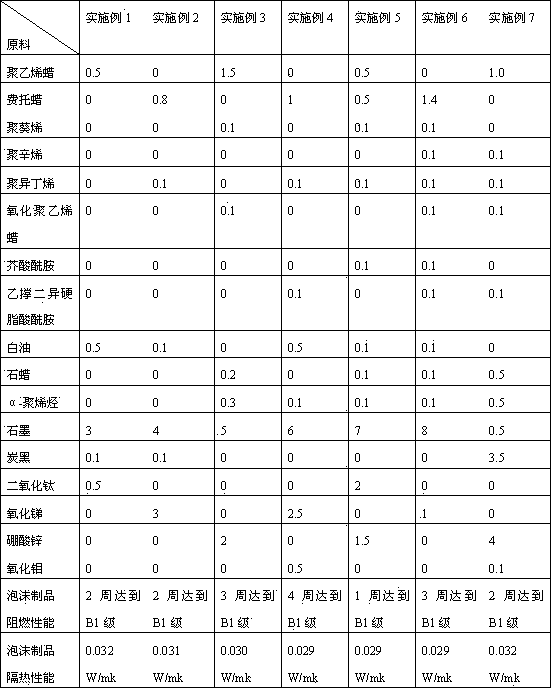

[0056] Table 1: The parts by weight of the following raw materials corresponding to the amount of styrene monomer taken in 1000 parts by weight

[0057]

[0058] The pre-dispersed particles obtained in the above-mentioned embodiments 1 to 7 are used to prepare expandable polystyrene particles:

[0059] In a 1000L reactor, add 400kg of deionized water while starting to stir and heat up, then add 20g of sodium dodecylbenzenesulfonate, 2.5kg of sodium disulfide, 1.25kg of calcium phosphate (TCP), and benzoyl peroxide Acyl (BPO) 1kg, tert-butyl peroxybenzoate (TBPB) 0.5kg, dicumyl peroxide (DCP) 1kg, styrene 250kg, add hexabromocycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com