Method for preparing bio-oil and/or pyrolytic gas by pyrolysis of biomass

A biomass pyrolysis and biomass technology, applied in the field of chemical industry, can solve problems such as harsh reaction conditions, high temperature and pressure, complex process, etc., and achieve the effect of low production cost, large profit margin, and simple equipment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

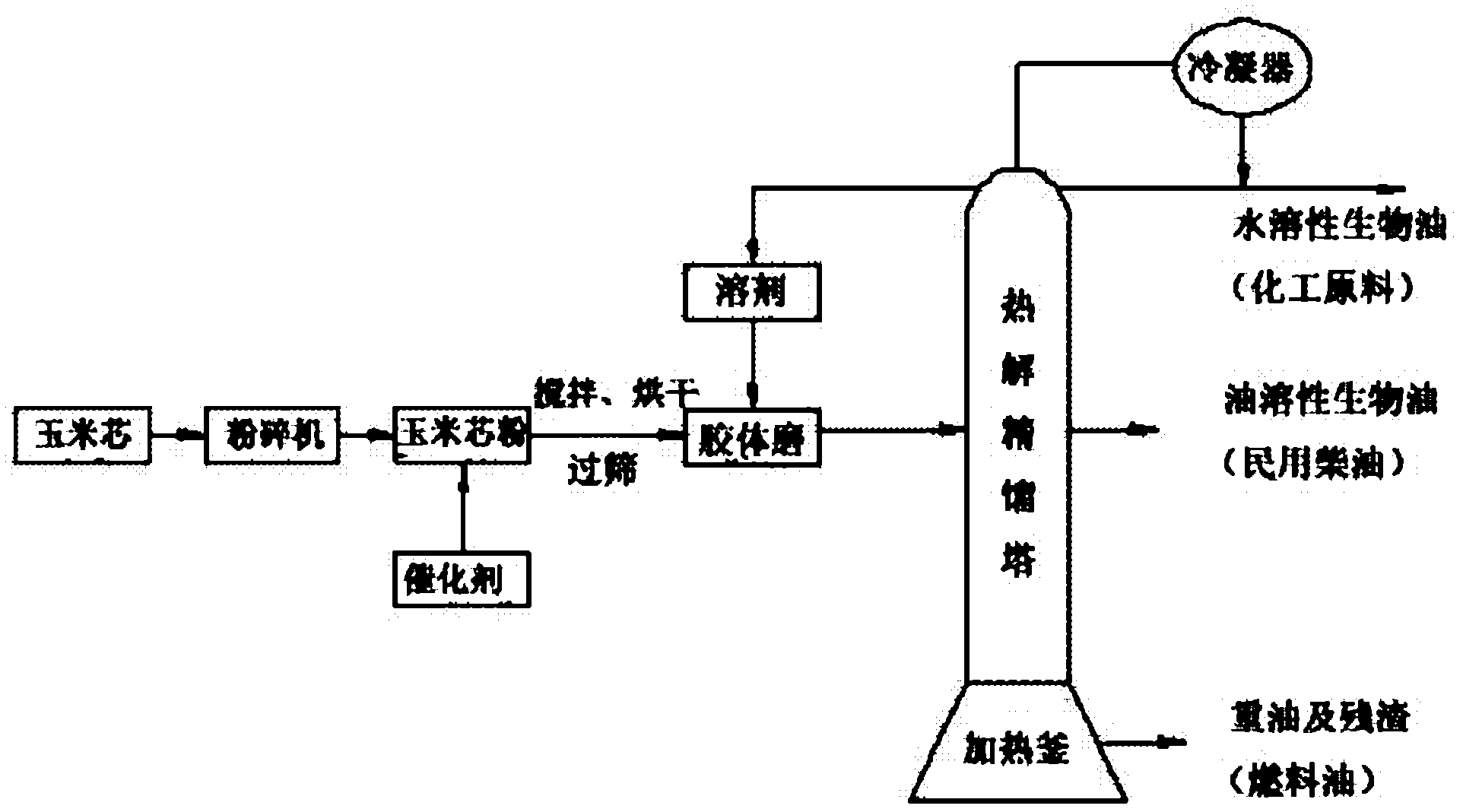

Image

Examples

Embodiment 1

[0048] 1. Weigh 20g of NaOH (analytical grade AR) and add it to 380g of tap water to obtain a 5% NaOH solution.

[0049] 2. After the dried corn cob (water content 5%-15%) is crushed by a pulverizer, it is passed through a 20-mesh sieve to obtain corn cob powder.

[0050] 3. Weigh 150g of the corncob powder obtained in step 2 and add it to 75g of the NaOH solution obtained in step 1, stir and mix well and let it stand for 3 hours, then put it in an oven at 80℃ for 12 hours to bake the dried corncob The powder is passed through a 20-mesh sieve to obtain a corncob powder containing catalyst.

[0051] 4. Weigh 31.8 g of corn cob powder obtained in step 3 and add 124.7 g of oil feet to the colloid mill and mix well to obtain a pyrolysis reactant with a corn cob content of 20% (hereinafter referred to as solid content). The reactant is added to the pyrolysis rectification tower, and pyrolyzed at normal pressure and 270° C. for 0.5 h to obtain pyrolysis liquid and pyrolysis gas. The liqu...

Embodiment 2

[0057] Steps 1-3 are the same as in Example 1. In Step 4, a material with a solid content of 30% is prepared. The other reaction conditions are the same as in Example 1. After the pyrolysis is completed, the liquid yield is 64.69% and the gas yield is 13.12%. , Repeated experiments on a solid content of 30%, the liquid yields obtained are all around 65%, and the repeatability is good.

[0058] The obtained bio-oil was tested, and the results are shown in Table 1.

[0059] Table 1 Bio-oil technical indicators

[0060] Analysis Project

[0061] 10% recovery temperature, ℃

[0062] The results show that the obtained bio-oil has a high calorific value of 41.59MJ / kg, which is higher than the calorific value of fuel oil (39.8MJ / kg). At the same time, the density, flash point, mechanical impurities and other indicators are similar to fuel oil and can be used to replace fuel oil. . It can also be further processed to obtain biodiesel or an emulsification process can be used to prepa...

Embodiment 3

[0068] Steps 1-3 are the same as in Example 1. In Step 4, a material with a solid content of 40% is prepared. The pyrolysis time is 0.3h. Other reaction conditions are the same as in Example 1. After the pyrolysis is completed, the liquid yield is 57.83%. , The gas yield is 18.20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com