Cascading distributed fiber Raman temperature measuring system

A distributed optical fiber, Raman temperature measurement technology, applied in thermometers, measurement devices, measurement of heat and other directions, can solve the problem of no distributed temperature measurement system, eliminate adverse effects, reduce measurement errors, and resist electromagnetic interference. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so as to better understand the present invention.

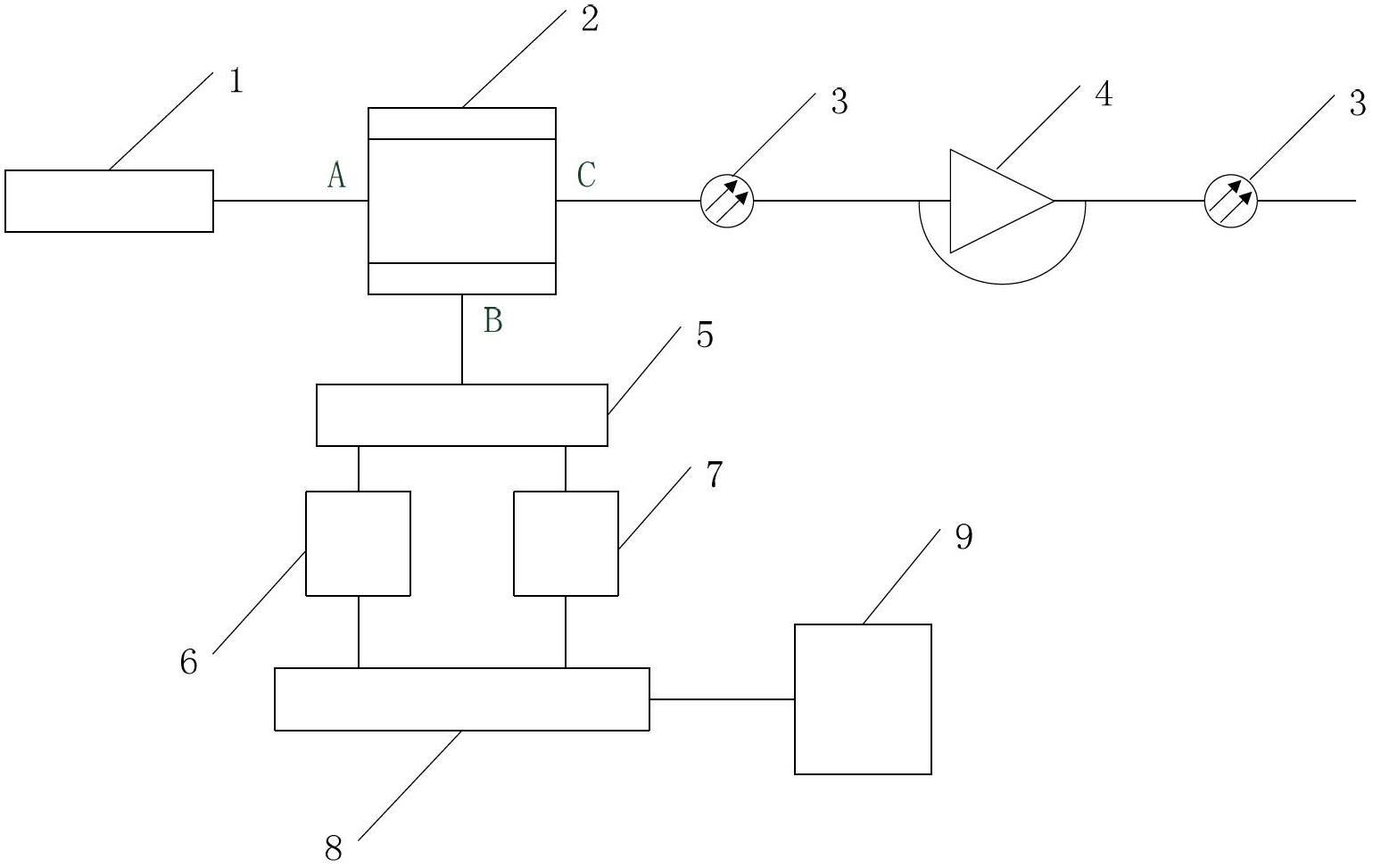

[0019] Such as figure 1 As shown, the cascadable distributed optical fiber Raman temperature measurement system of the present invention includes: a broadband light source 1, a bidirectional three-channel coupler 2, a single-mode optical fiber 3, an optical relay amplifier 4, an optical splitter 5, and a first photoelectric receiver 6 , a second photoelectric receiver 7, a signal acquisition card 8 and a computer 9; wherein the A port and the C port of the bidirectional three-channel fiber coupler 2 are respectively connected to a broadband light source 1 and a single-mode optical fiber 3, and the B port is connected to an optical splitter 5; The two ends of the amplifier 4 are respectively connected to the single-mode optical fiber 3 in sequence; the two beams of light split by the optical splitter 5 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com