Method for preparing bacteriostasis dental repair composite resin

A composite resin, dental restoration technology, used in dental preparations, dentistry, dental prostheses, etc., can solve the problem of uneven dispersion affecting the antibacterial and mechanical properties of resin, the antibacterial effect needs to be studied, and the color stability of materials, etc. problems, to achieve the effect of low color stability, excellent mechanical properties, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

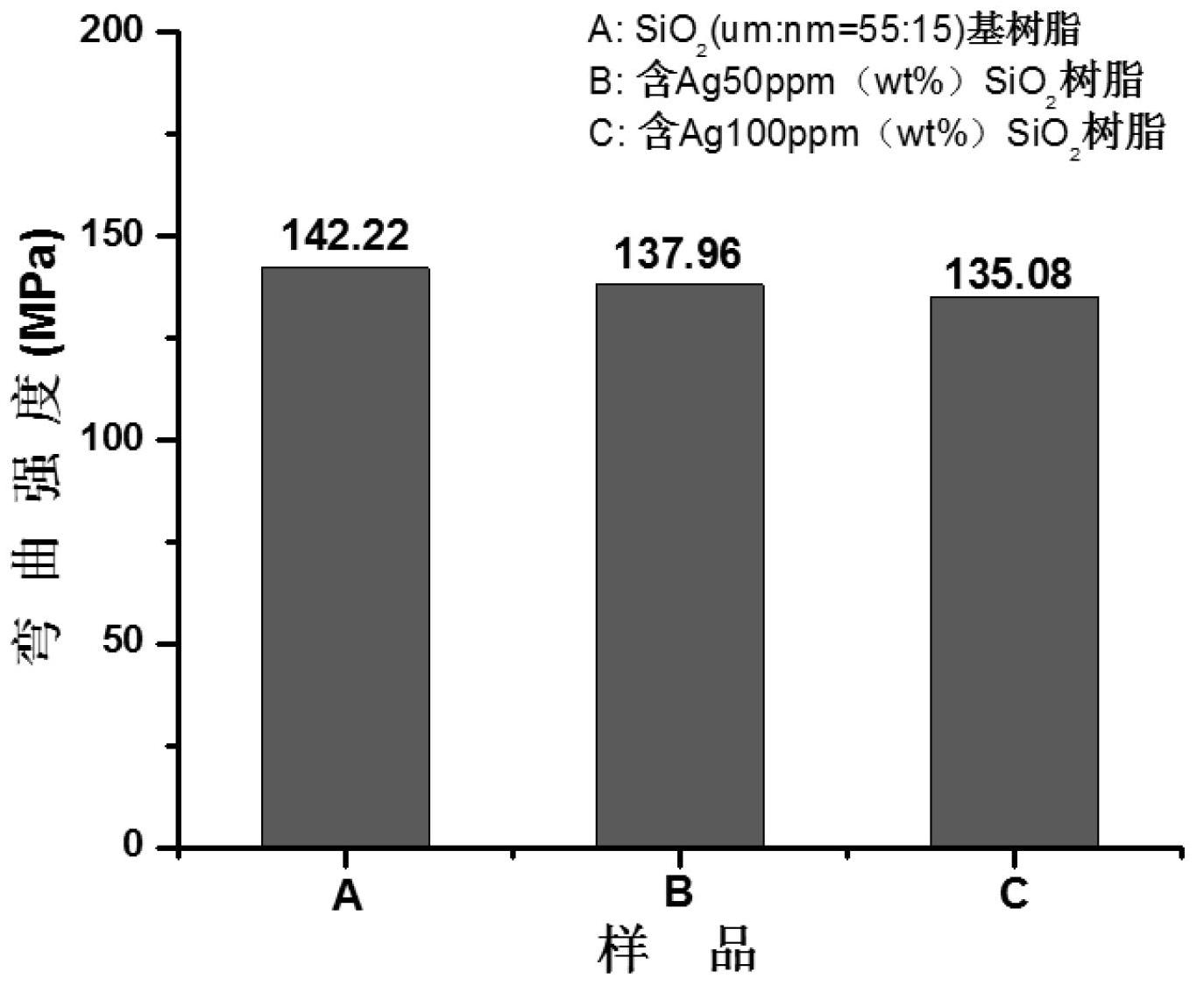

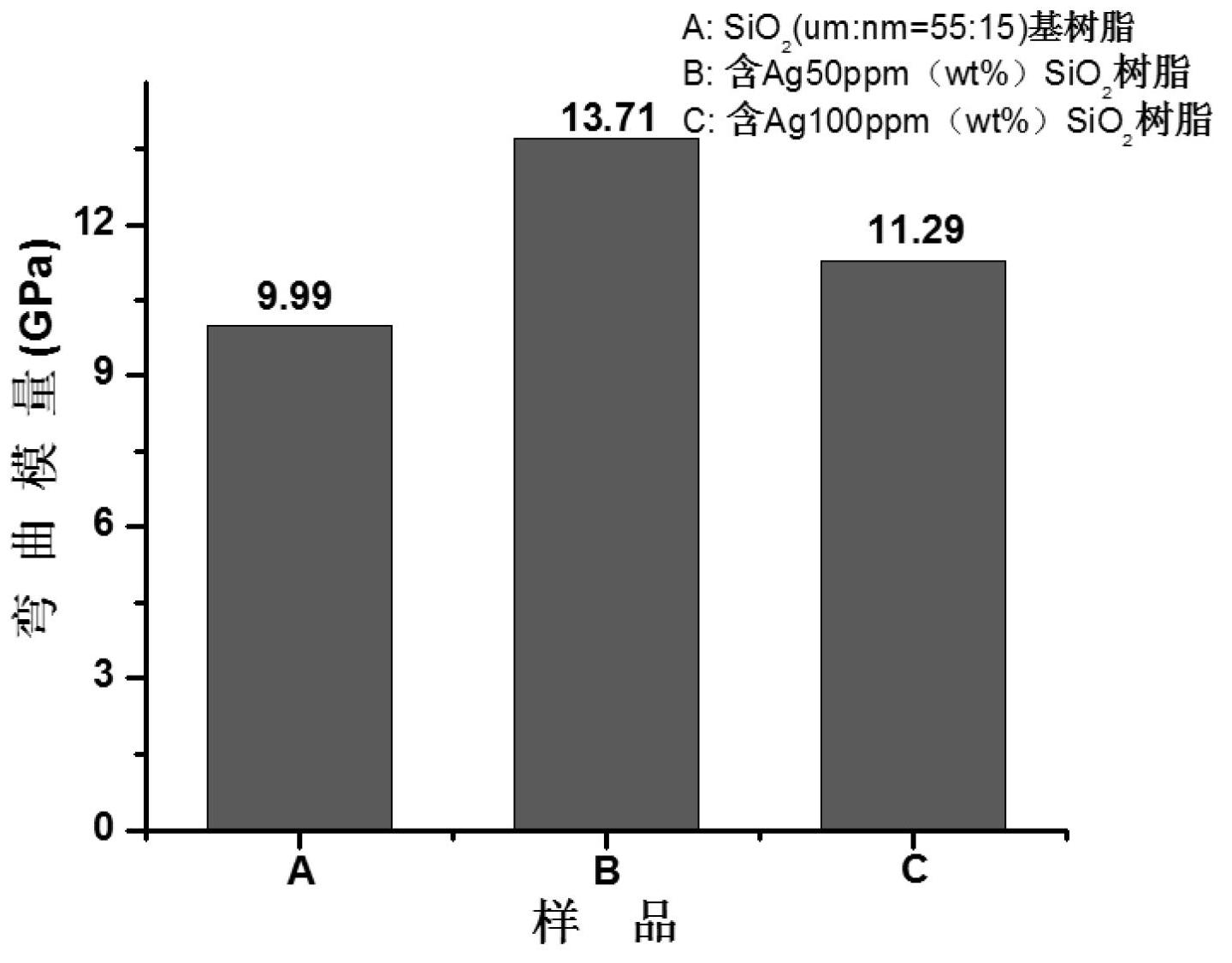

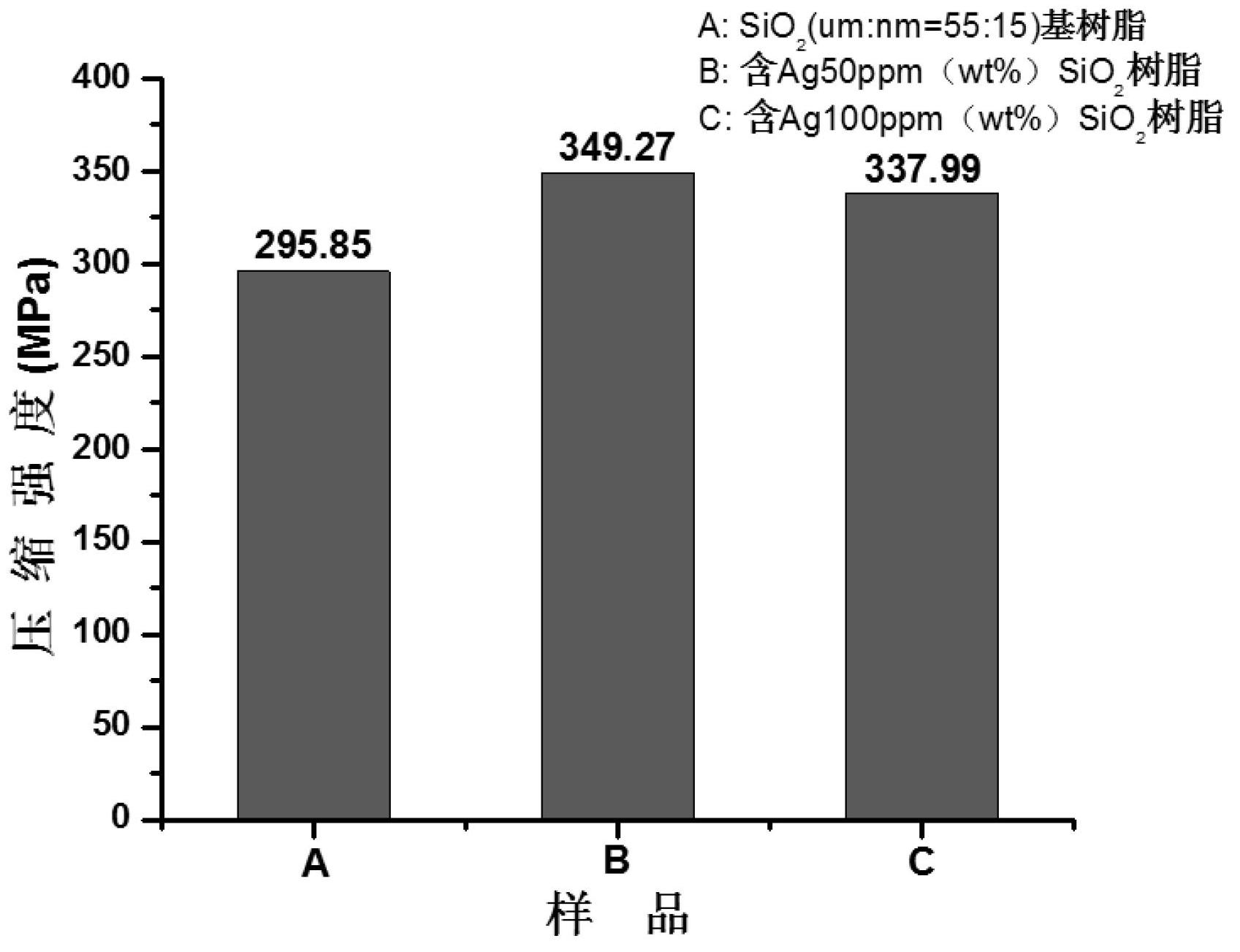

Embodiment 1

[0031] (1) In 200mL of cyclohexane, add 0.00050g of surface-modified nano-silver, 5.50000g of modified fumed silica with an average particle size of 1μm and 1.50000g of an average particle size of 40nm, and place it in an oscillating ultrasonic machine after mechanical stirring , ultrasonically dispersed for 30 minutes, and the solvent was distilled off under reduced pressure at 60°C to obtain a composite functional filler.

[0032] (2) Add a small amount of composite functional filler in step (1) to the organic monomers of 1.50000g bisphenol A-glycidyl methacrylate and 1.50000g triethylene glycol dimethacrylate, and add 0.00600g of camphorquinone and 0.02400g of ethyl 4-N,N-dimethylaminobenzoate were premixed, and then further mixed uniformly by an ultra-fine three-roll mixer to obtain an uncured composite resin paste with a filling amount of 70%.

[0033] (3) The uncured composite resin paste in step (2) is cured by visible light (460-480nm) for 40 seconds to obtain a light-...

Embodiment 2

[0036] (1) In 240ml of cyclohexane, add 0.00200g of surface-modified nano-silver, 5.50000g of modified fumed silica with an average particle size of 1μm, 1.20000g of an average particle size of 40nm and 0.80000g of modified hydroxyapatite Whiskers were mechanically stirred and placed in an oscillating ultrasonic machine, ultrasonically dispersed for 30 minutes, and the solvent was distilled off under reduced pressure at 60°C to obtain a composite functional filler.

[0037] (2) Add 1.00000g of bisphenol A-glycidyl methacrylate, 1.00000g of ethoxylated bisphenol A diester methacrylate, 0.50000g of bisphenol A-glycidyl methacrylate, and 0.50000g of dimethacrylate Add 0.00500g of 1-phenyl-1,2-propanedione and 0.02000g of 4-N,N-dimethylaminobenzoic acid ethyl ester to the organic monomer of triethylene glycol ester, and then pass through the ultrafine The three-roll mixer further mixed evenly to obtain an uncured composite resin paste with a filling amount of 75%.

[0038] (3) Th...

Embodiment 3

[0040] (1) In 200ml of cyclohexane, add 0.00100g of surface-modified nano-silver, 5.50000g of modified fumed silica with an average particle size of 1μm and 1.50000g of an average particle size of 40nm, and place it in an oscillating ultrasonic machine after mechanical stirring , ultrasonically dispersed for 30 minutes, and the solvent was distilled off under reduced pressure at 60°C to obtain a composite functional filler.

[0041] (2) Add a small amount of composite functional filler in step (1) to the organic monomers of 1.50000g bisphenol A-glycidyl methacrylate and 1.50000g triethylene glycol dimethacrylate, and add 0.00600g of camphorquinone and 0.02400g of ethyl 4-N,N-dimethylaminobenzoate were premixed, and then further mixed uniformly by an ultra-fine three-roll mixer to obtain an uncured composite resin paste with a filling amount of 70%.

[0042] (3) The uncured composite resin paste in step (2) is cured by visible light (460-480nm) for 40 seconds to obtain a light-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com