A low-alkali quick-hardening stone adhesive preparation method and an adhesive thereof

An adhesive and stone technology, applied in the field of adhesives, can solve the problems of polluted stone surface, long construction period, poor bonding strength, etc., and achieve the effects of simple preparation process, high production efficiency, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

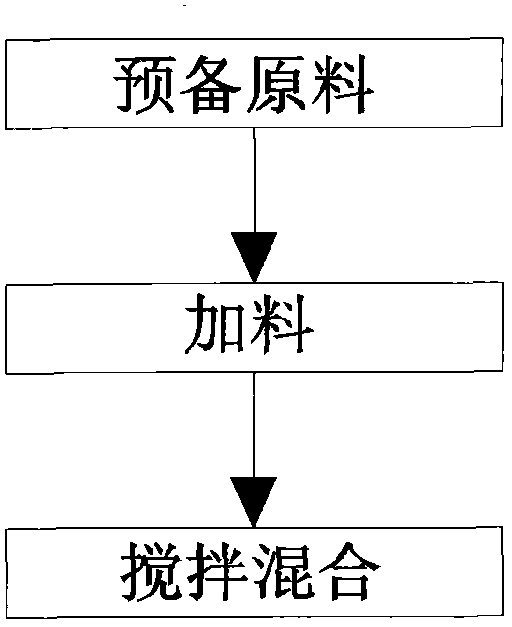

[0056] Embodiment 1: see figure 1 A method for preparing a low-alkali quick-hardening stone adhesive provided in this embodiment is characterized in that it comprises the following steps:

[0057] (1) Prepare raw materials: the components and weight ratios of the raw materials are as follows:

[0058] Portland cement 300Kg,

[0059] High alumina cement 70Kg,

[0060] Anhydrite 50Kg,

[0061] 40-70 mesh quartz sand 326Kg,

[0062] 80-120 mesh quartz sand 200Kg,

[0063] Redispersible latex powder 25Kg,

[0065] Water reducer 2.4Kg,

[0066] Metakaolin 20Kg,

[0067] Tartaric acid 2Kg,

[0068] Lithium carbonate 0.6Kg;

[0069](2) Feeding: first add half of Portland cement, high alumina cement, 40-70 mesh quartz sand and 80-120 mesh quartz sand into the mixing equipment, and then add anhydrite, redispersible latex powder, cellulose Ether water reducer, metakaolin, tartaric acid and lithium carbonate are added to the mixing equipment, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com