Method for preparing m-xylylenediamine

A technology of m-xylylenediamine and isophthalonitrile, which is applied in the field of preparing m-xylylenediamine, can solve the problems of poor m-xylylenediamine selectivity, high reaction pressure and high energy consumption, and achieve improved selectivity and reduced Effects of Reaction Pressure and Energy Consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

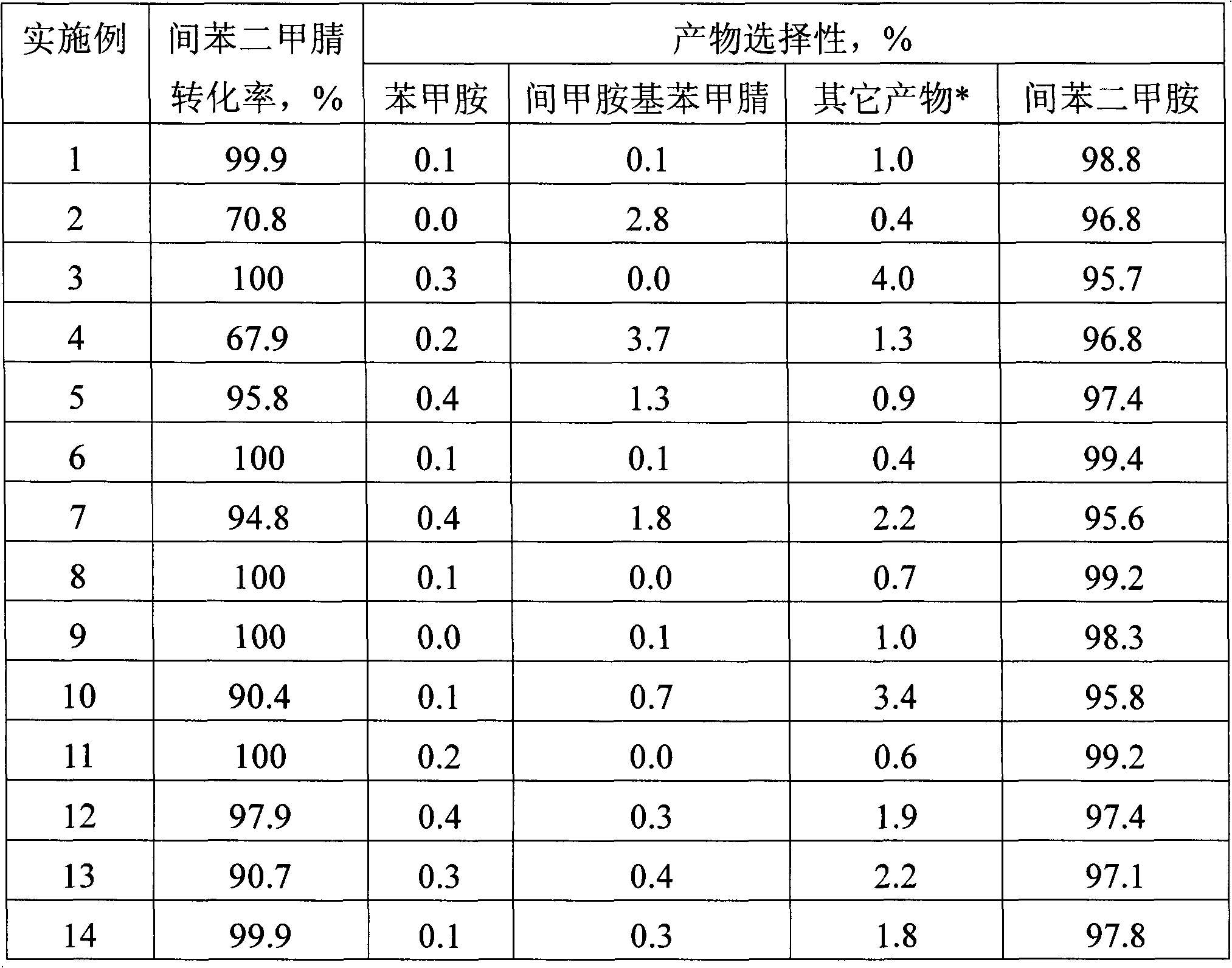

Examples

Embodiment 1

[0017] The catalyst used is 10%Ni-5%Cu-5%Re / diatomaceous earth. The carrier is diatomaceous earth, which is sieved into 20-40 mesh. The catalyst active components Ni, Cu and Re were supported on the carrier diatomite by conventional impregnation method. 3.0 grams of catalyst were activated by hydrogen before the reaction, and the activation conditions were: GHSV=1000h -1 , 0.2MPaG, 375°C, reduction time 5 hours. A trickle bed reactor is used. At a reaction temperature of 80°C and a reaction pressure of 10.0MPaG, H 2 / isophthalonitrile=100 (molar ratio), isophthalonitrile / m-xylylenediamine / NH 3 =10:10:80 (weight ratio), isophthalonitrile liquid space velocity is 0.8h -1 , the reaction time is 50h, sampling analysis. SE-30 capillary column, FID detector. Normalized by area. The results of the reactions are summarized in Table 1.

Embodiment 2

[0019] Adopting reaction temperature is 60 ℃, other conditions are identical with embodiment 1.

Embodiment 3

[0021] Adopting reaction temperature is 100 ℃, other conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com