Chitooligosaccharide quaternary ammonium salt and its synthesis method

A technology of chitosan oligosaccharides and quaternary ammonium salts, applied in chemical instruments and methods, botanical equipment and methods, amino sugars, etc., can solve problems such as fracture, chitosan oligosaccharides are easy to oxidize, and are not suitable for large-scale preparation. High efficiency, non-cytotoxicity, and favorable effects for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

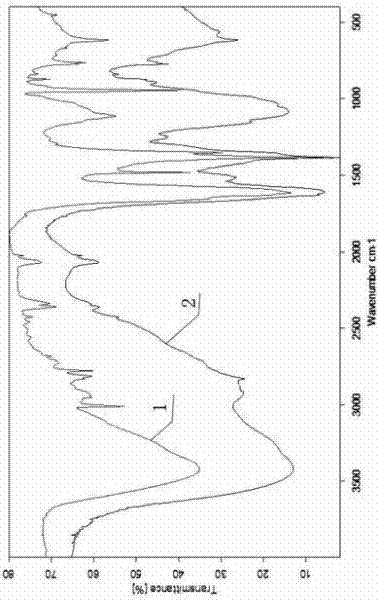

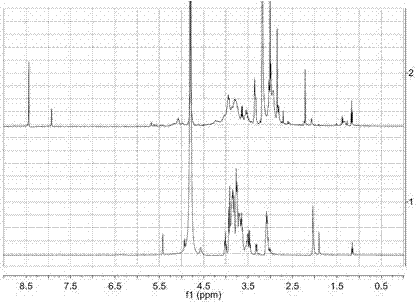

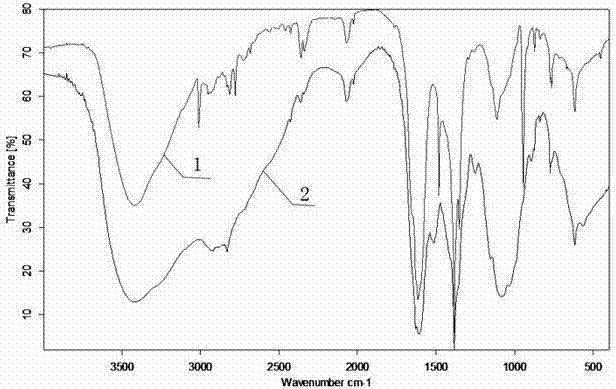

Image

Examples

Embodiment 1

[0021] Example 1. A kind of chitosan oligosaccharide quaternary ammonium salt, its structural formula is as shown in formula (1),

[0022]

[0023] Formula 1)

[0024] The value of n is 0~15.

Embodiment 2

[0025] Example 2. A kind of preparation method of chitosan oligosaccharide quaternary ammonium salt as described in embodiment 1, its steps are as follows: take the mixture of dimethyl sulfate and water as solvent, the volume ratio of dimethyl sulfate and water in the solvent is 4:1 , using dimethyl sulfate as a methylation reagent; during preparation, oligochitosan is added to the solvent to make oligochitosan solution, the mass volume ratio concentration of oligochitosan solution is 4%, and then oligochitosan is added to the solution respectively 0.5 times the mass of NaOH and NaCl, magnetically stirred, and reacted at room temperature for 6 hours; the reaction solution was precipitated with 3 times the volume of acetone, filtered with suction, the filter cake was washed, dried, and the quaternary ammonium salt of chitosan oligosaccharide was obtained.

Embodiment 3

[0026] Example 3. A kind of preparation method of chitosan oligosaccharide quaternary ammonium salt as described in embodiment 1, its steps are as follows: take the mixture of dimethyl sulfate and water as solvent, and the volume ratio of dimethyl sulfate and water in the solvent is 8:1 , using dimethyl sulfate as a methylation reagent; during preparation, oligochitosan is added to the solvent to make oligochitosan solution, the mass volume ratio concentration of oligochitosan solution is 10%, and then oligochitosan is added to the solution respectively 4 times the mass of NaOH and NaCl, magnetically stirred, and reacted at room temperature for 18 hours; the reaction solution was precipitated with 5 times its volume of acetone, filtered with suction, the filter cake was washed, and dried to obtain the quaternary ammonium salt of chitosan oligosaccharide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com