Method for mechanically separating river crab shell and meat

A separation method, a technology for separating shell and meat, which is applied in the fields of crustacean processing, slaughtering, food science, etc., can solve the problems of high manual labor intensity, affecting product safety, and residual meat on the shell, so as to reduce labor intensity, shell Improved meat separation efficiency and good crab meat quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] The invention provides a method for separating the shell meat of river crab, wherein one embodiment comprises the following steps:

[0028] 1) Cleaning, that is, cleaning the river crabs with a combination of brushing and water washing;

[0029] 2) Cooking, that is, put it in a cooking pot and cook for 8-10 minutes;

[0030] 3) Pre-treatment, that is, removing inedible parts such as dorsal shell, gills, and lungs;

[0031] 4) Classification, that is, to separate and classify the crab body, crab legs and crab claws;

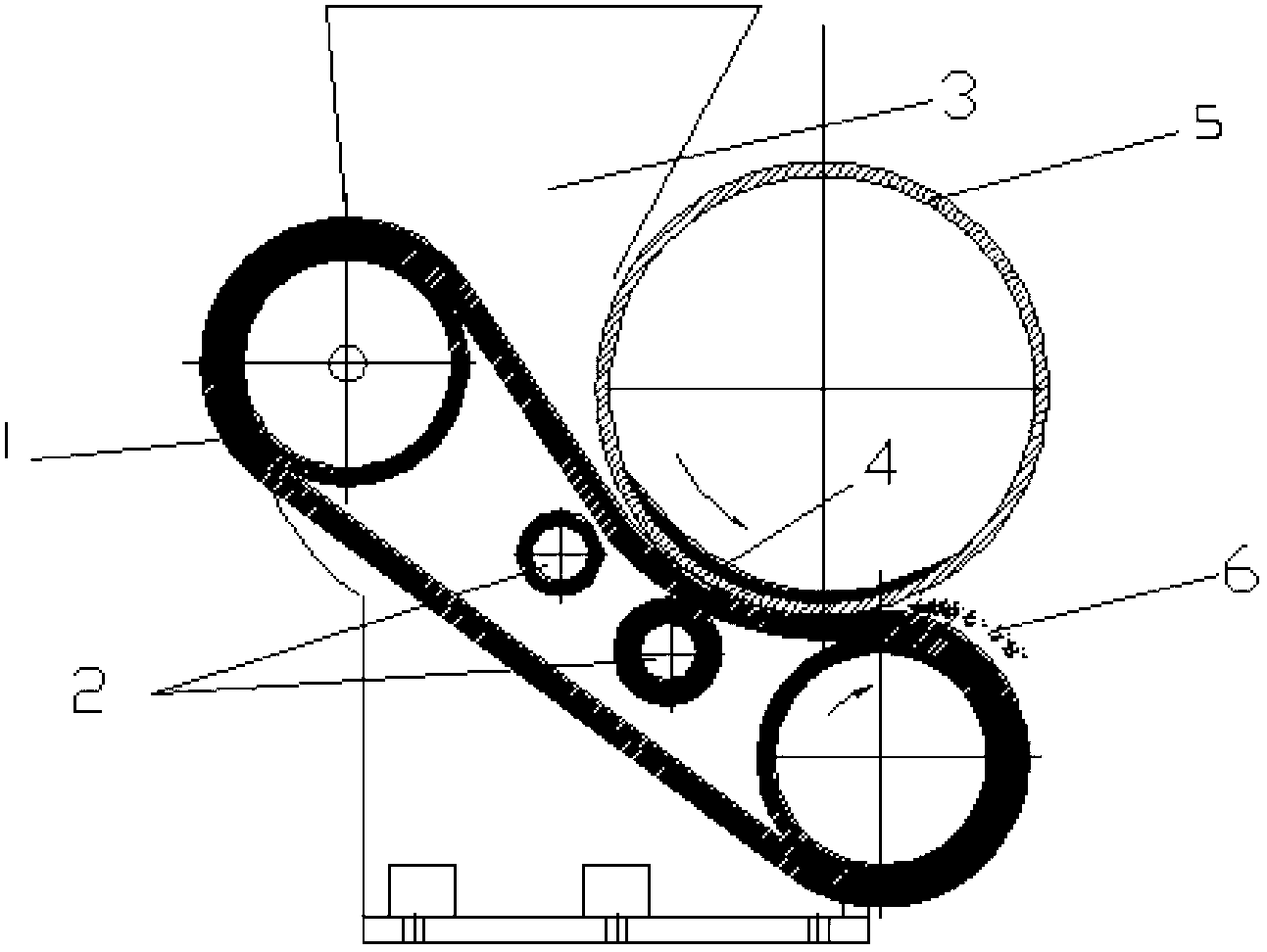

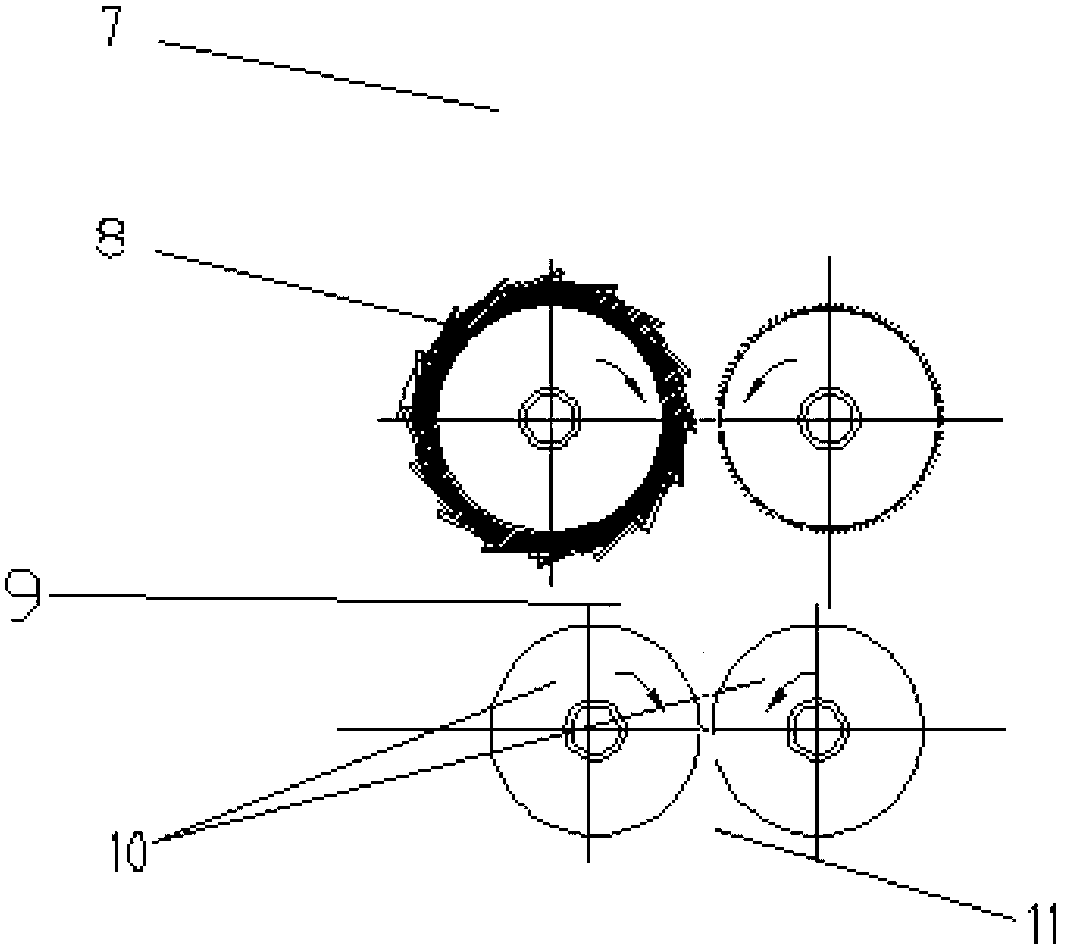

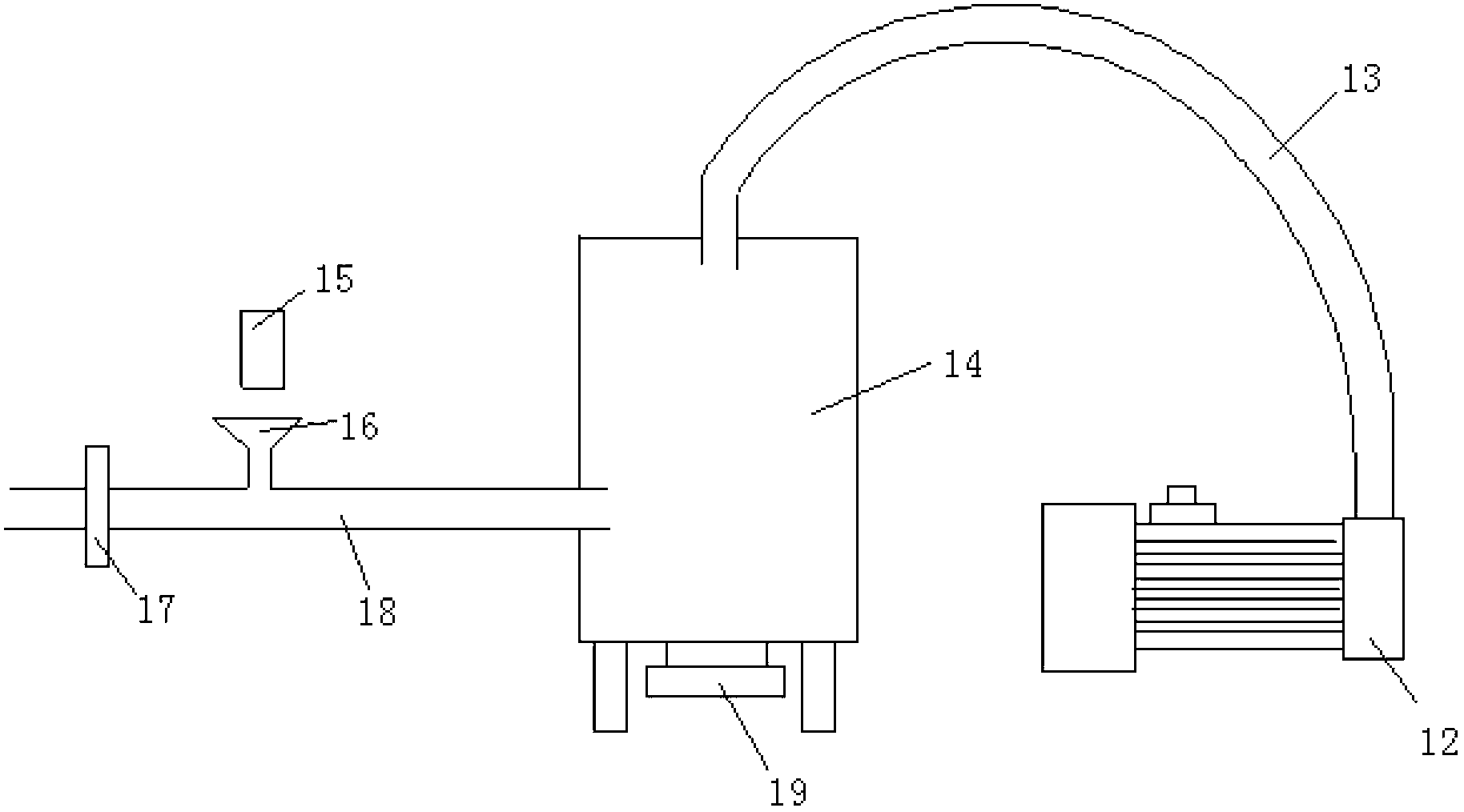

[0032] 5) The crab body is separated from the shell by belt extrusion, that is, the crab body 3 is placed on a belt 1 driven by a pulley. The tension can be adjusted according to the tightness of the crab body and shell meat. One or more idler rollers 2 are set under the belt 1, and one or more sieve cylinders 5 with one end open and the other end closed are set above the belt. The hole diameter of the hole cylinder is 2.5-3mm, and the total area of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com