Control method for moving mechanism of all-wheel-drive combined attracting-type wall-climbing robot

A crawling robot and composite adsorption technology, which is applied in the direction of manipulators, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of leading, not being able to drive the front wheel, and not being able to solve the sensor, etc., to achieve no additional delay, good real-time tracking performance, The effect of good responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

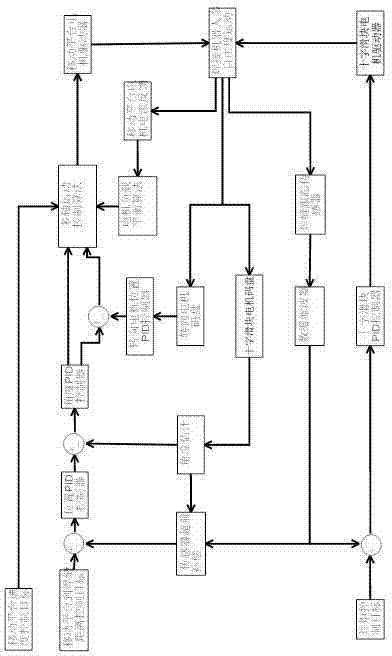

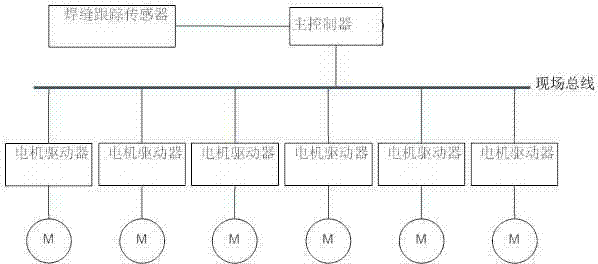

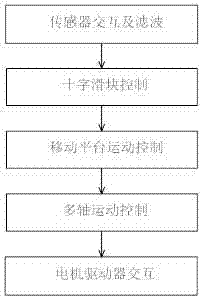

[0042] A control method for the motion mechanism of a fully-driven composite adsorption crawling robot. The control object of the method is a fully driven crawling that uses a laser seam tracking sensor as a seam tracking sensor and a cross slider as an actuator. Type welding robot, its specific steps are:

[0043] A. Obtain the two-dimensional weld position information provided by the seam tracking sensor, and perform filtering processing; the equipment used in step A is a data filter, and the filtering processing method in step A is: through a certain amount of historical data to compare the current value Estimate and judge the data based on the estimated value and the error threshold to remove the wrong data.

[0044]The steps of the filtering processing method are: based on the historical data of at least the first 10 periods, the estimated data is calculated using the sliding window smoothing filter method. If the error between the measured value and the estimated value e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com