Advanced treatment device for vitamin C production waste water and application method thereof

A production wastewater and advanced treatment technology, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of high salt content in sewage, complex process flow, high operating costs, etc. problem, to achieve the effect of obvious treatment effect, reasonable economy and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

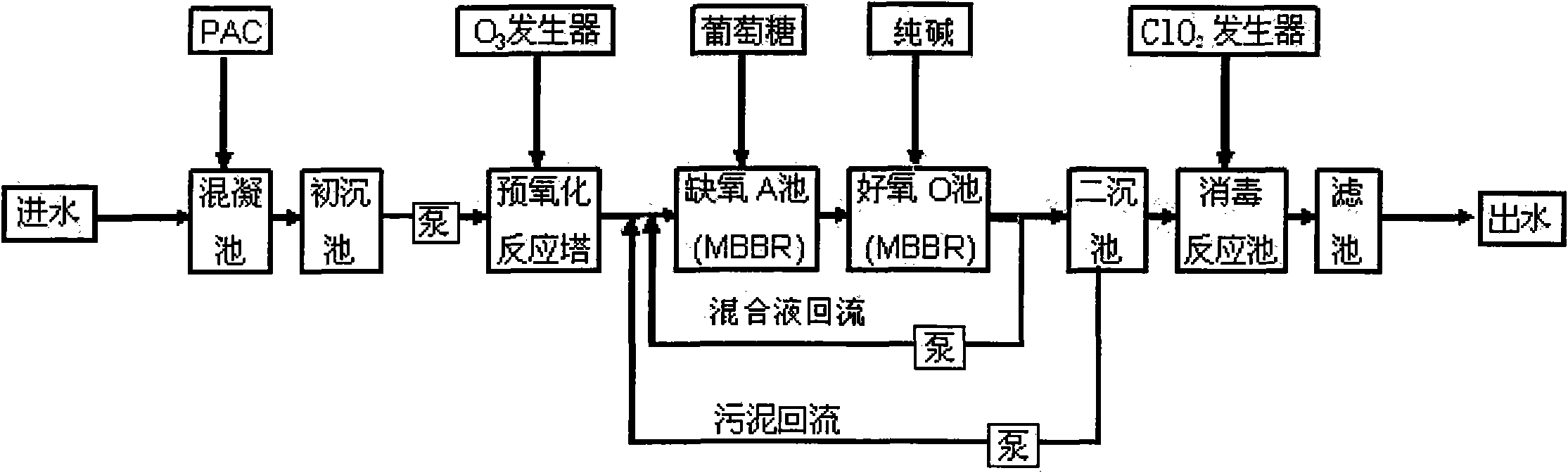

Method used

Image

Examples

example 1

[0049] Example 1: Test water source: The test water is normal drainage from the sewage treatment plant in the Sinopharm Group Weisheng Pharmaceutical Factory. The water quality indicators are as follows: COD: 200-500mg / L, NH 3 -N: 5-15mg / L, TN: 30-60mg / L; test water intake: 1.0m 3 / h; temperature: air temperature 20-25℃, water temperature 20-25℃.

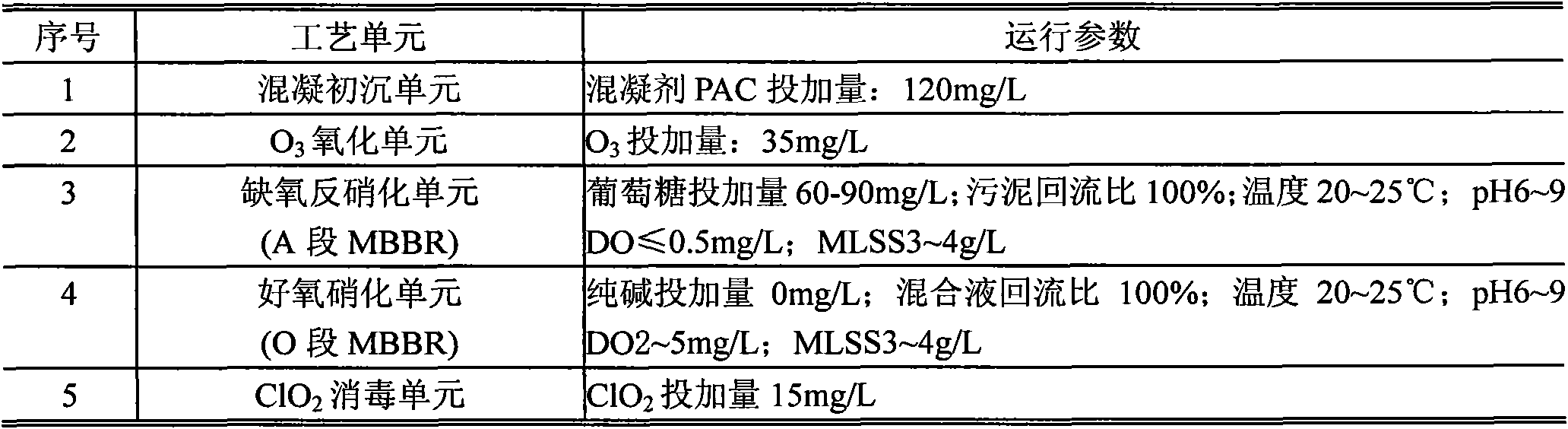

[0050] The operating parameters of each process unit are as follows:

[0051]

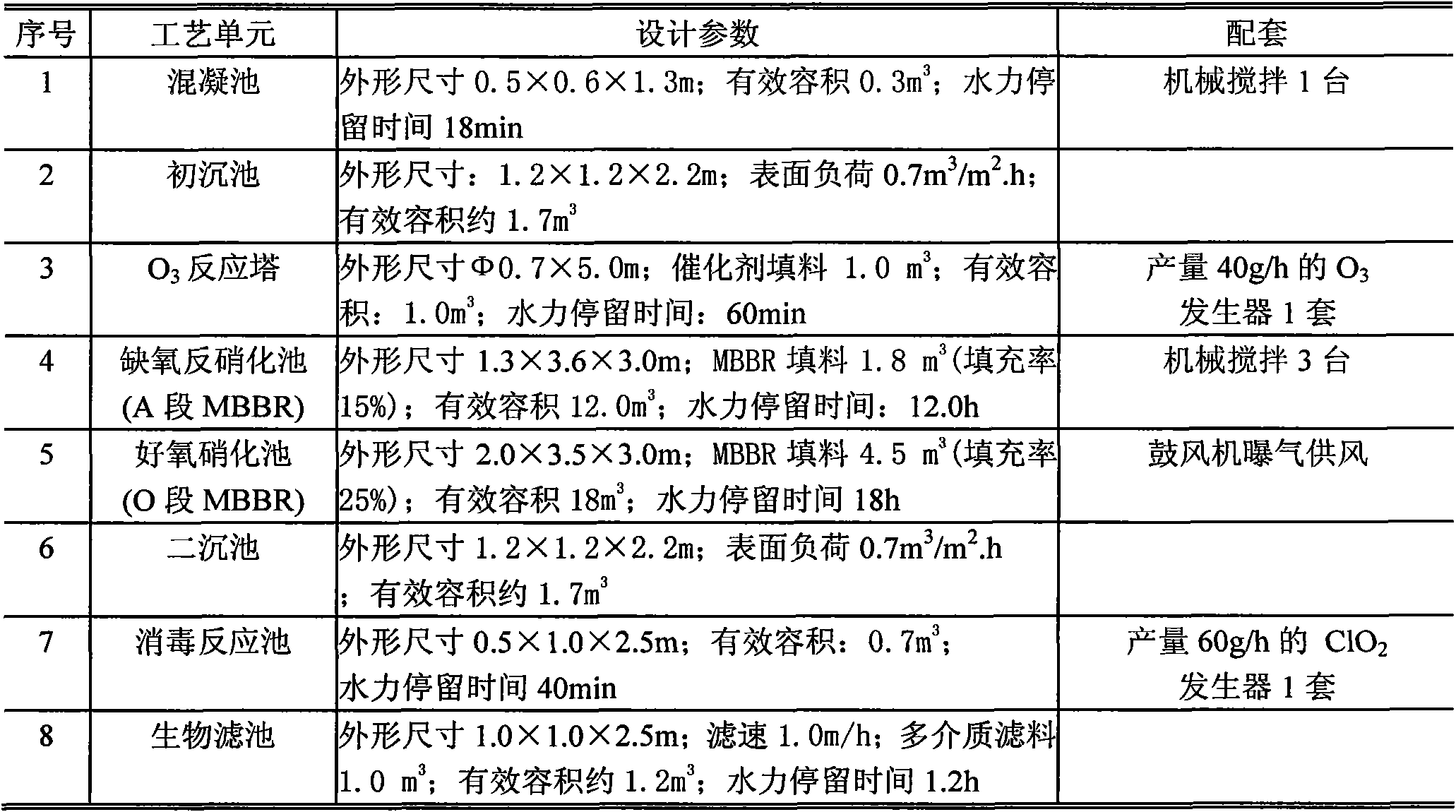

[0052] The design parameters of each process unit are as follows:

[0053]

[0054] The data during the normal operation of the test is as follows (unit: mg / L):

[0055]

example 2

[0056] Example 2: Test water source: The test water is a mixture of mother liquor from the product workshop of Sinopharm Group Weisheng Pharmaceutical Co., Ltd. and normal drainage from the factory's sewage treatment plant. The water quality indicators are as follows: COD: 200-500mg / L, NH 3 -N: 5-15mg / L, TN: 30-60mg / L; test water intake: 1.0m 3 / h; temperature: air temperature -10-5℃, water temperature 13-15.5℃. The design parameters of each process unit are the same as in Example 1.

[0057] The operating parameters of each process unit are as follows:

[0058]

[0059] The data during the full-load test period of the test is as follows (average water temperature: 14℃, unit mg / L):

[0060]

example 3

[0061] Example 3: Test incoming water is a mixture of mother liquor from CSPC Weisheng Pharmaceutical's product workshop and normal drainage from the factory's sewage treatment plant. The water quality indicators are as follows: COD: 372-2150mg / L, NH 3 -N: 54.4-323mg / L, TN: 77-349mg / L; test water intake: 1.0m 3 / h; temperature: air temperature -10-5℃, water temperature 13-15.5℃; the design parameters of each process unit are the same as in Example 1.

[0062] The operating parameters of each process unit are as follows:

[0063]

[0064] The data during the test impact assessment period is as follows (average water temperature: 14℃, unit mg / L):

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com