Mono-component polymer-cement waterproof mortar

A technology of waterproof slurry and polymer, which is applied in the field of building materials, can solve problems such as the inability to realize the multiple utilization of remaining powder, damage to the performance and durability of waterproof materials, increase in product transportation and storage costs, and achieve excellent waterproof performance and adhesiveness. Strong knot, not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

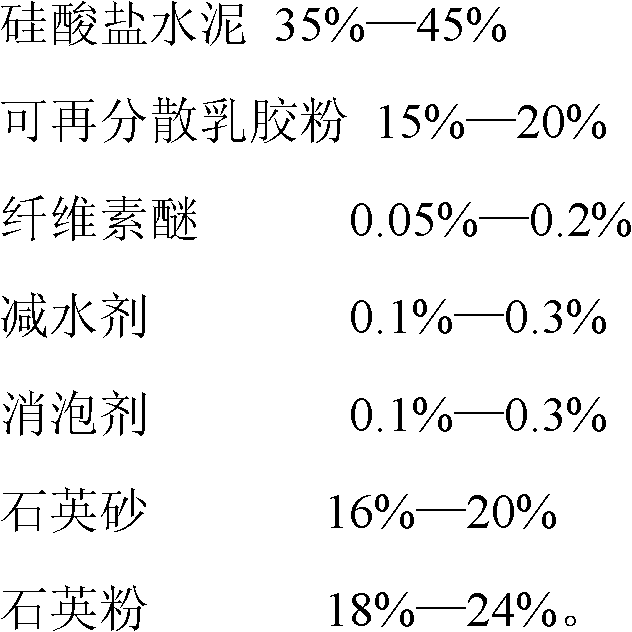

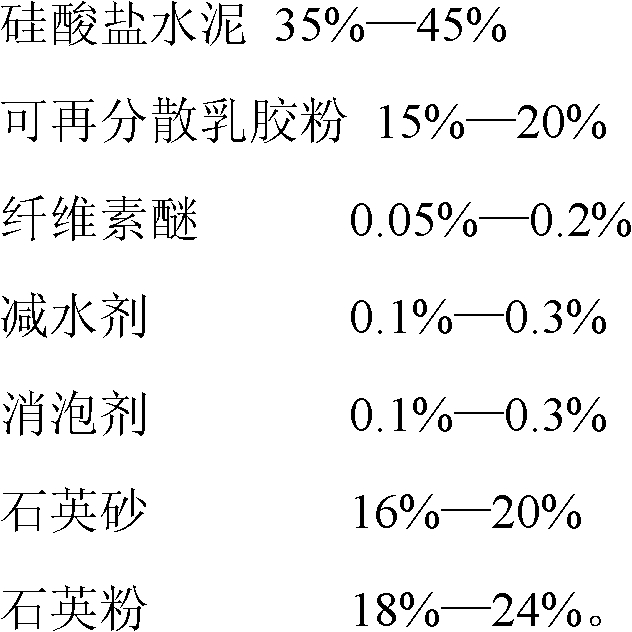

[0028] The composition of the single-component polymer cement waterproof slurry of the present embodiment is (in proportion by weight) 35% of ordinary portland cement, 15% of redispersible latex powder, 0.05% of cellulose ether, 0.1% of Water agent, 0.1% defoamer, 0.05% wood fiber, 4% 600 mesh talcum powder, 20% 80-120 mesh quartz sand, 24% 200 mesh quartz powder, 0.5% pigment.

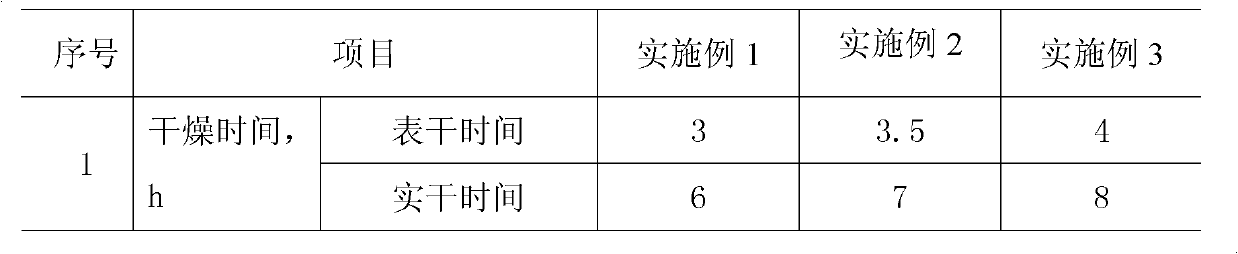

[0029] During use, when the amount of water added to the formula waterproof slurry is 25% of the total amount of dry powder, the test results of the main properties of the slurry coating are shown in Table 1.

Embodiment 2

[0031] The composition of the single-component polymer cement waterproof slurry of the present embodiment is (by weight) 40% of ordinary Portland cement, 15% of redispersible latex powder, 0.2% of cellulose ether, 0.3% of disinfectant Foaming agent, 0.2% wood fiber, 6% 600 mesh talcum powder, 16% 80-120 mesh quartz sand, 20% 200 mesh quartz powder, 0.5% pigment.

[0032] During use, when the amount of water added to the formula waterproof slurry is 25% of the total amount of dry powder, the test results of the main properties of the slurry coating are shown in Table 1.

Embodiment 3

[0034] The composition of the single-component polymer cement waterproof slurry of the present embodiment is (by weight) 45% of ordinary portland cement, 20% of redispersible latex powder, 0.2% of cellulose ether, 0.3% of disinfectant Foaming agent, 0.2% wood fiber, 4% 600 mesh talcum powder, 16% 80-120 mesh quartz sand, 20% 200 mesh quartz powder, 0.5% pigment.

[0035] During use, when the amount of water added to the formula waterproof slurry is 25% of the total amount of dry powder, the test results of the main properties of the slurry coating are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com