Compound fertilizer sustained release agent and preparation method thereof

A slow-release agent and compound fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of affecting the slow-release effect of fertilizers, cracks on the particle surface, and high production costs, so as to inhibit the excessive release of nutrients and improve the utilization rate. , to avoid the effect of water eutrophication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A compound fertilizer slow-release agent, its mass ratio is 100 parts of phenol, 10 parts of water, 100 parts of formaldehyde, and 15 parts of urea.

Embodiment 2

[0031] A preparation method of compound fertilizer slow-release agent, its steps are as follows:

[0032] a. Soak the iron bucket filled with phenol in hot water at 60-70°C and melt it;

[0033] b. adding mass ratio to the polymerization reactor is 100 parts of molten phenol, 10 parts of water, heating and stirring;

[0034] c. When the temperature of the reaction kettle is raised to 60-65°C, add sodium hydroxide with a mass ratio of 6 parts, and adjust the pH to 8-8.5;

[0035] d. Add formaldehyde with a mass ratio of 100 parts to the reactor, and react at 65-70°C for 70-90 minutes;

[0036] e. Heat up the reaction kettle to 70-80°C and react for 60-120 minutes;

[0037] f. Add urea with a mass ratio of 15 parts into the reactor, and react for 30 to 60 minutes.

Embodiment 3

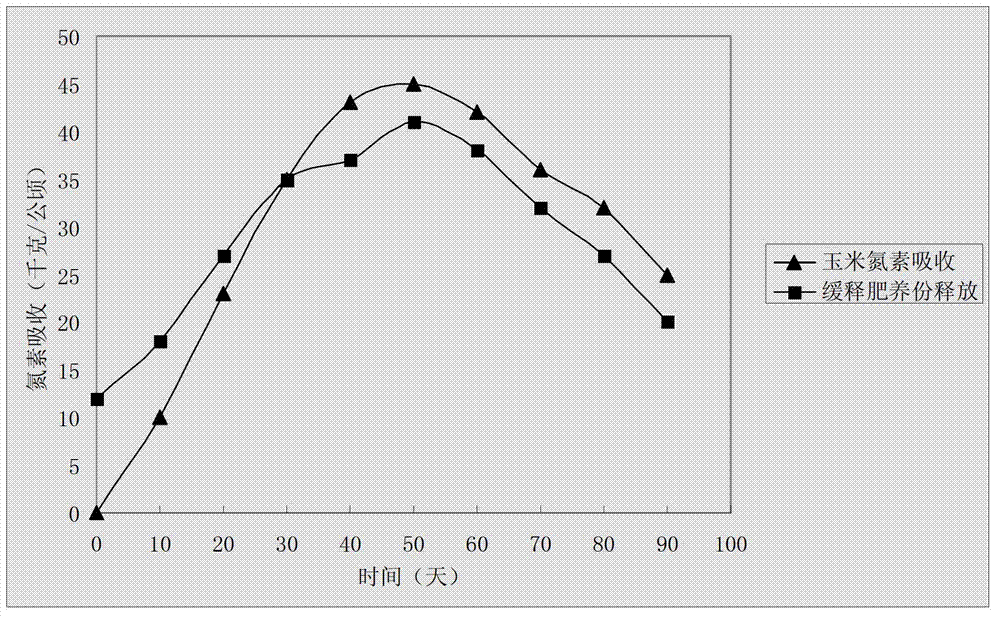

[0039] refer to figure 1 As shown, in the first 30 days of early corn planting, in order to meet the nitrogen demand of corn, the slow-release fertilizer releases nitrogen at a faster rate, so that the release of slow-release fertilizer nitrogen is higher than the nitrogen uptake of corn . After 30 days, the release rate of slow-release fertilizer nitrogen slowed down, but still increased with the increase of corn nitrogen absorption, and the release fertilizer released nitrogen at a fixed ratio slightly lower than the corn nitrogen absorption . Until the 50th day of the corn planting period, after the amount of nitrogen released by the slow-release fertilizer and the amount of nitrogen absorbed by the corn both reached their peaks, the amount of nitrogen released by the slow-release fertilizer was synchronized with the amount of nitrogen absorbed by the corn at a fixed ratio. Decrease, not only to ensure the whole process of corn growth process for nitrogen needs, but also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com