Coupling production process for preparing methyl acetate and butyl acetate

A technology of methyl acetate and butyl acetate, which is applied in the field of coupling production process for the preparation of methyl acetate and butyl acetate, can solve the problems of high energy consumption and material consumption, azeotropic carry-over, etc., to improve production efficiency and reduce heating The effect of reducing product energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

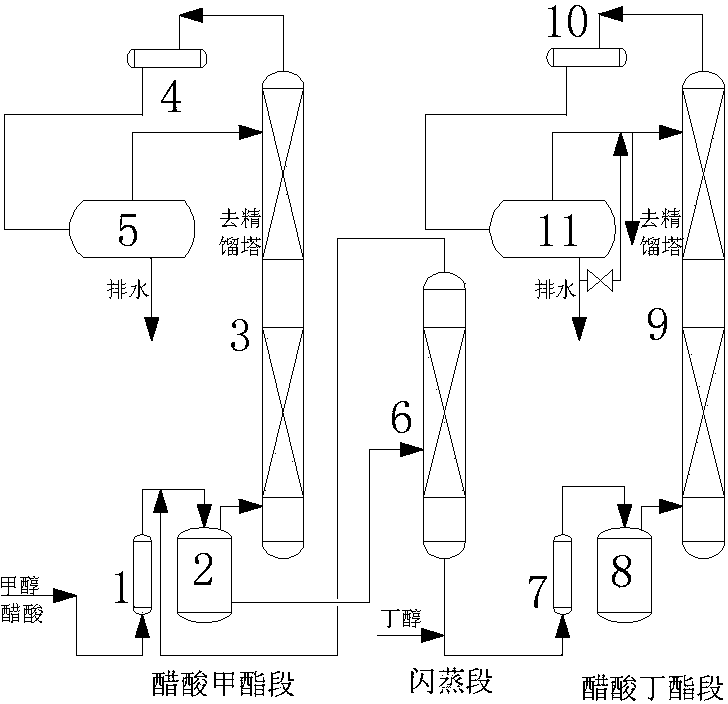

[0031] Such as figure 1 As shown, the raw material methanol and acetic acid enter the methyl acetate reboiler 1 at a molar ratio of 1:1.6, and the feed rate is 1800L / h. After mixing and preheating, they enter the methyl acetate esterification reactor 2 for esterification reaction. The product enters the methyl acetate esterification tower 3 in the form of an azeotrope, and then enters the methyl acetate overhead condenser 4 and the methyl acetate phase separator 5 for processing and then enters the rectifying tower. Methyl acetate is esterified at 95°C in the bottom of the tower, 68°C in the tower, and 56.3°C at the top of the tower, and the acid in the still is controlled at 65%~66%. Simultaneously extract a part of the still liquid and enter the flash tower 6 for processing, the flow of extracting the still liquid is 645L / h, and the low boiler methyl acetate and water are steamed from the top of the flash tower, which is connected to the plug behind the methyl acetate reboil...

Embodiment 2

[0033] Such as figure 1As shown, the raw material methanol and acetic acid enter the methyl acetate reboiler 1 at a molar ratio of 1:1.7, and the feed rate is 2000L / h. After mixing and preheating, they enter the methyl acetate esterification reactor 2, and then further heat up for reaction. The reaction product enters the methyl acetate esterification tower 3 in the form of an azeotrope, and then enters the methyl acetate overhead condenser 4 and the methyl acetate phase separator 5 for processing and then enters the rectifying tower. Methyl acetate is esterified at 98°C in the bottom of the tower, 70°C in the tower, and 56.5°C at the top of the tower, and the acid in the still is controlled at 70%~71%. Simultaneously extract a part of the still liquid and enter the flash tower 6 for processing. The flow of extracting the still liquid is 750L / h. The temperature of the tube and the bottom of the tower is controlled at 106°C~108°C, and the temperature at the top of the tower is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com